POWER GUN SUCTION BLAST TOOLS

Page 8

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 24189, Rev. C 06/18

5.3.2

Open the water valve only after the pulling the

trigger to begin blasting and closed before releasing the

trigger to stop blasting.

NOTICE

Open the water valve only after pulling the

trigger to begin blasting and always close it

before releasing the trigger to stop blasting.

Failure to have the water valve closed when the

trigger is released can allow water to flow into

the mixing chamber and material hose, causing

blockage from wet abrasive.

5.4

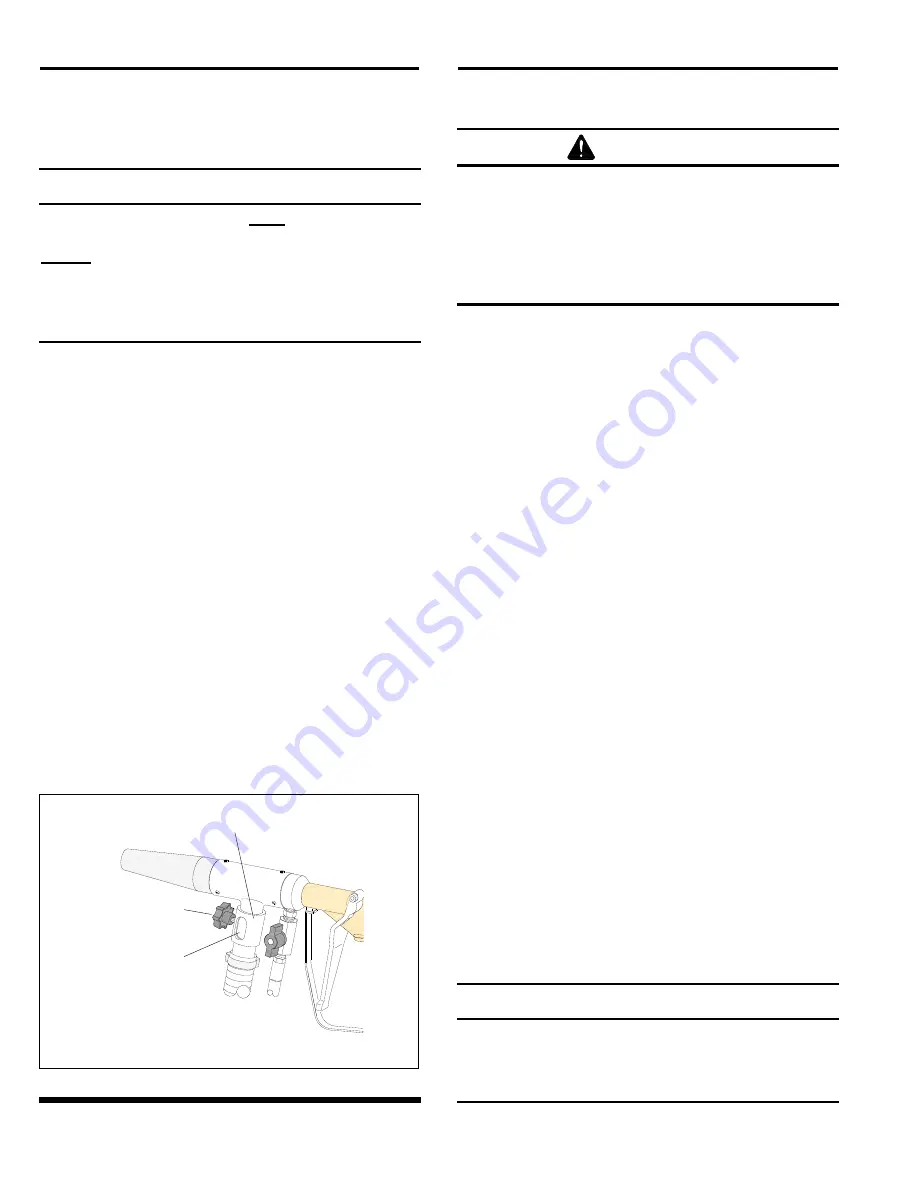

Air-Induction Valve (stops abrasive flow)

Figure 12

5.4.1

Opening the air-induction valve disrupts the

vacuum used to pull abrasive into the mixing chamber

allowing air only (no abrasive) to exit the nozzle. This step

is used to blow off dry abrasive from the blast surface or

assist in drying a wet surface after wet blasting.

5.4.2

To stop abrasive flow, loosen the tensioning

knob and rotate the sleeve to fully open the induction

port. Close the valve to resume blasting.

Wash Down:

If the water valve is open, air and water

continue to flow through the nozzle (as long as the

trigger is pulled) to wash off the blast surface. Refer to

Section 4.6.5.

Air Drying and Blow-Off:

If the water valve is closed,

air continues to flow through the nozzle (as long as the

trigger is pulled) to blow-off dry surface or assist in dry

wet surfaces. Refer to Section 4.6.6.

Figure

12

6.0 MAINTENANCE

WARNING

Failure to observe the following procedure

before performing any maintenance or service

can cause serious injury or death from the

sudden release of compressed air.

Lockout and tagout the compressed-air

supply.

Bleed the air-supply line.

Periodically inspect the air jet, mixing chamber, nozzle,

and material hose for wear.

6.1

Removing Nozzle and Air Jet:

There are no

threads on the mixing chamber; the jet and nozzle are

held onto the mixing chamber with three setscrews. Use

a 2.5 mm hex key to loosen the setscrews and while

twisting the nozzle and jet to loosen them, pull out to

remove them from the mixing chamber.

6.2

Nozzle:

A new nozzle has a 1/2" ID orifice.

Replace the nozzle when its diameter has increased by

more than 1/16" (9/16” ID) or sooner if suction

diminishes noticeably.

6.3

Air Jet, Dry Blast

Refer to Section 6.4 to service the H2O air jet.

NOTE: Breakaway thread sealant is used on the

threads between the air jet and gun. The sealant

prevents parts from rotating out of alignment during

operation. When removing the jet, use a strap

wrench or similar wrench that will not damage the

shaded areas shown in Figure 13. If a wrench that

can damage the surface must be applied to remove

the jet, the jaws must be placed in the recess area as

shown in Figure 13.

6.3.1

Separate the air jet from the mixing chamber.

Use a 2.5 mm hex key to loosen the three setscrews

holding the jet to the mixing chamber and while twisting

the jet to loosen it, pull out to remove it from the chamber.

6.3.2

Replace the air jet when wear reaches the orifice

and affects the overall length. New air-jet orifices are 1/4"

ID and extend approximately 1-5/16" from the jet body.

NOTICE

When removing and installing an air jet, do not

put a wrench on the shaded areas shown in

Figure 13. The jet is a slip fit into the mixing

chamber; gouges will interfere with the fit.

Induction Valve Sleeve

Tensioning Knob

Air Induction Port

Shown open.