APOLLO 20 LP SUPPLIED-AIR RESPIRATOR

Page 9

8.0

CLEANING

CAUTION

Follow washing instructions as described in this

section. Do not use any caustic chemicals or

solvents that may be irritating or harmful to the

user, or which change the properties of the mate-

rials used in any part of the respirator.

8.1

Outer Cape

8.1.1

The cape can be machine washed using warm

water and mild detergent. Dry in a clothes dryer at the

lowest temperature setting. Do not dry clean. See Section

9.4 for removal and installation instructions.

8.2

Sweatband and Suspension

8.2.1

The sweatband, suspension, suspension strap,

and chin strap should be washed using warm water and

mild detergent. See Section 6.1 for removing the suspen-

sion.

8.3

Helmet Assembly

8.3.1

The helmet assembly should be wiped clean with

mild detergent and water. DO NOT IMMERSE THE HEL-

MET IN WATER! While this does not permanently damage

the helmet, it will require an extended drying period.

8.3.2

Care must be used to prevent abrasive entry when

putting on or removing the respirator and when changing

lenses. Vacuum the inside of the helmet to remove any

abrasive.

8.4

Inner Lens

8.4.1

Inner and middle lenses should be replaced when

pitted or scratched; however if they become dirty but not

pitted, use mild detergent and water to clean them. Volatile

solutions such as alcohol, gasoline or ammonia must not

be used to clean these lenses. Allow the lens to air dry;

cloth and towels can scratch the lens surface.

9.0

SERVICE MAINTENANCE

CAUTION

Clean the respirator of dust and media before

maintenance. All maintenance must be done in a

clean environment away from dust and media.

Doing so will help prevent ingress of dust and

contaminants.

9.1

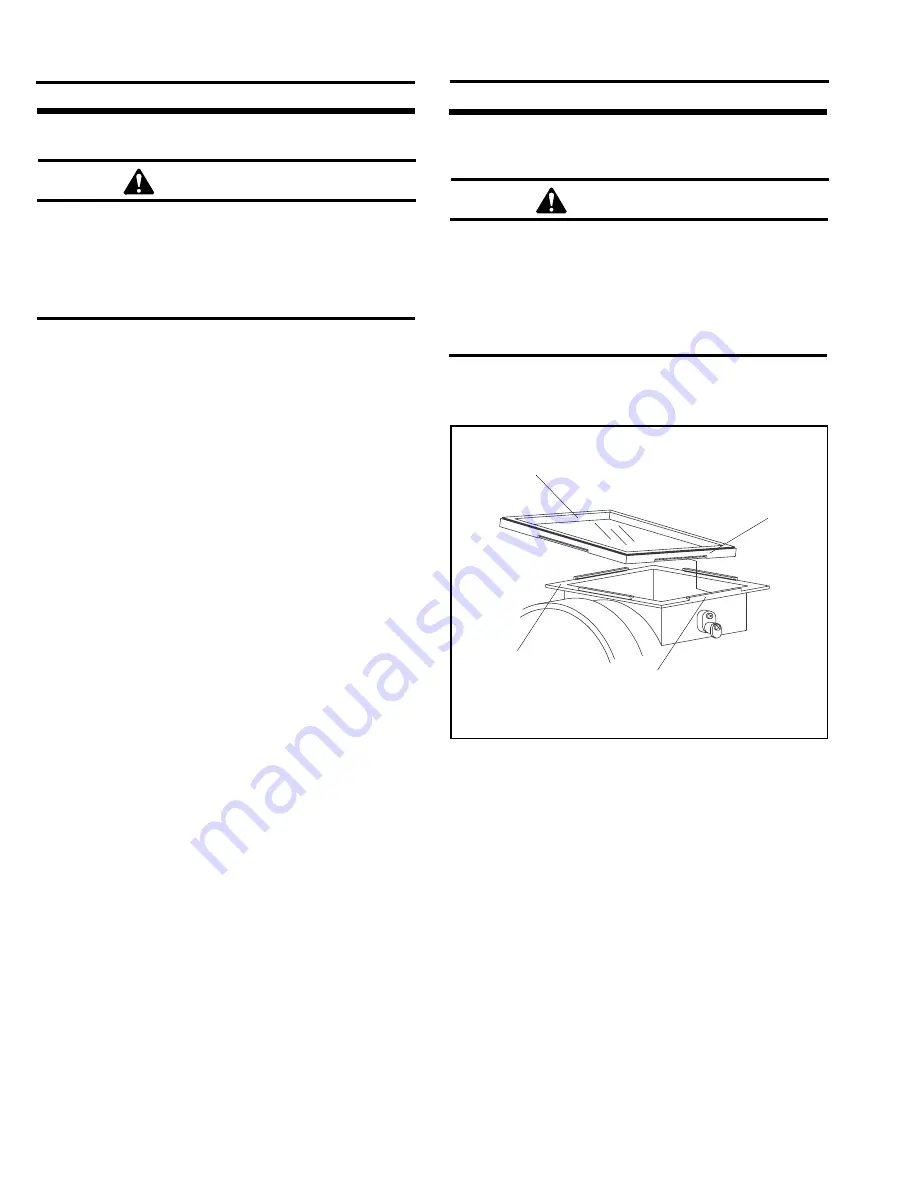

Replacing Inner Lens, Ref. Figure 3

9.1.1

Open the lens frame.

9.1.2

Remove the middle lens and cover lenses.

9.1.3

Pull the lens gasket and inner lens off the window

opening flange. The gasket is held in place by tabs on the

flange, that fit into slots on the gasket.

9.1.4

Remove the old lens from the gasket lens channel,

and clean the gasket.

9.1.5

Place a new lens into the gasket lens channel. The

lens must be in place before affixing the gasket to the

window opening.

9.1.6

Identify the retaining slots on the gasket, and the

holding tabs located on the helmet window opening shown

in Figure 3.

Figure 3.

Retaining Slot

(one on each

side)

Window

Opening Flange

Lens Gasket

with Inner Lens

Holding Tab

(one on each side)