APOLLO 20 LP SUPPLIED-AIR RESPIRATOR

Page 6

WARNING

Never connect a breathing air line to an air source

that has not been tested for gas and particulate

contamination. The presence of unacceptable

levels of carbon monoxide (CO) or other gases in

the breathing air will cause death to the user.

4.1.2

Breathing air used to supply the respirator must be

respirable breathing air and contain no less than 19.5

volume-percent of oxygen. Breathing air shall also meet

the requirements for Grade D or higher quality, as de-

scribed in Compressed Gas Association Commodity Speci-

fication pamphlet G-7.1., titled Commodity Specification

For Air, published by Compressed Gas Association Inc.,

Arlington, VA. (42 CFR Chapter 1).

4.1.3

Prior to using the respirator, read the owner’s

manual and all instructions, labels, and warnings relating

to the ambient air pump.

4.1.4

Take precautions to prevent contaminants from

entering through the air pump’s inlet filter. Locate the air

pump’s inlet filter away from all sources of contaminants

including carbon monoxide, which is found in engine

exhaust, and in any form of combustion. Place the pump

in an area away from vehicle traffic. Do not locate the

pump’s inlet filter near any exhaust system outlet, ventila-

tion flue, or source of fumes or particles of any kind. If the

ambient air pump cannot be placed in an area where

respirable air can be guaranteed, use an air inlet extension

hose as specified by the pump manufacturer to bring air

from an area where clean respirable air is ensured.

4.2

Air Volume and Pressure

4.2.1

The Apollo 20 LP respirator is designed for use

with ambient pumps, that provides 6 to 15 cfm of Grade D

breathing air at pressures as noted in the table in Section

4.2.2. According to OSHA regulations, the respirator

provides adequate protection at 6 cfm. While 6 cfm is the

minimum required air flow, test data show that when 7 cfm

or more is used it provides even greater protection for the

user.

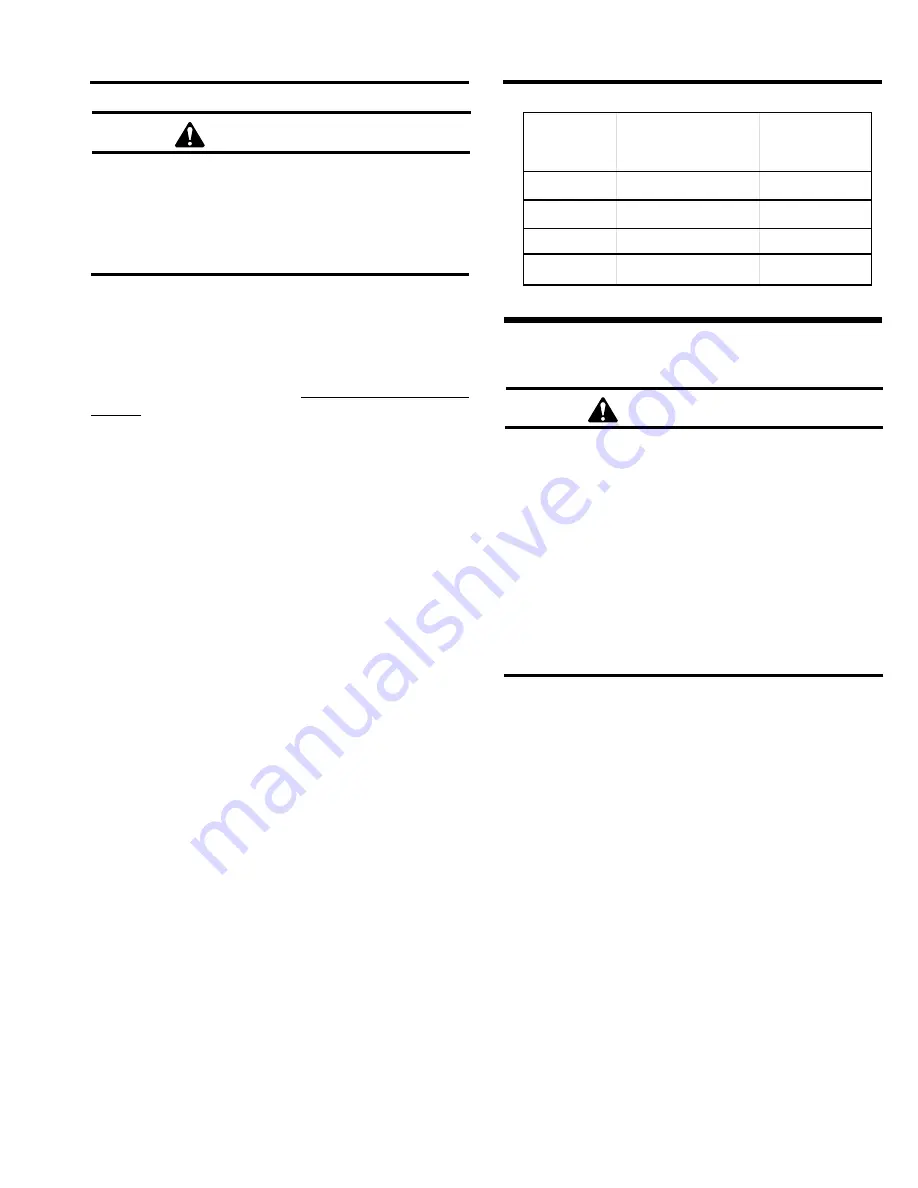

4.2.2

Use the following table to determine the minimum

and maximum pressure setting and maximum respirator

hose length.

Total Hose

Length

Maximum Number

of Hose Sections

Pressure (psi)

Min. Max.

50 feet

1

6

to

10

100 feet

2

8

to

14

200 feet

2

11

to

20

300 feet

3

15

to

20

5.0

OPERATION

WARNING

• With the respirator on, leave the blast area

immediately if any of the following conditions

occur:

• Any part of the respirator system becomes dam-

aged.

• Any air monitoring alarm is activated.

• Airflow into the respirator is reduced or stops.

• Breathing becomes difficult.

• At the first sign of dizziness, nausea, fever,

illness or injury.

• Any contamination is noted by taste, smell or

vision inside the respirator.

• Vision becomes impaired.

• Any irritation is noted.

5.1

Prior to operation, thoroughly inspect and clean

the helmet, breathing tube, respirator hose, air entry ports,

and fittings of all dust and debris. Inspect the helmet

suspension and adjust if necessary per Section 6.1.

5.2

Begin operation of the ambient air pump per the

manufacturer’s instructions.

5.3

Check air pressure at the point of attachment. Set

the pressure between the minimum and maxium pres-

sures assigned in Section 4.2.2.

5.4

Check all safety, and breathing equipment used in

conjunction with the respirator as recommended by the

manufacturer.

5.5

Check respirator hose and connections for tight-

ness and leaks.

5.6

Put the respirator on in a clean non-hazardous

environment, free of contaminants, where the air is safe to

breathe. When putting the respirator on or taking it off,

keep it upright to prevent dust and abrasive from falling

inside.