CLASSIC BLAST MACHINE with TLR-100/300 REMOTE CONTROLS

Page 12

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22501, Rev. I 02/18

3.2.9

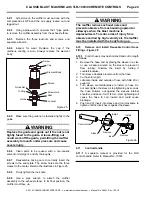

Make sure that the safety petcock located on the

inlet valve is open. Open position is when the lever is

aligned with the petcock, as shown in Figure 11.

Figure

11

3.2.10

Make sure the remote control handle lever is in

the up (no blast) position, as shown in Figure 12, and

that the handle lever and safety lock move freely.

Figure

12

WARNING

A separate manual is supplied with the remote

control handle. Do not operate the machine

before reading the remote control handle

operating instructions.

3.2.11

Make sure the rubber seal under the handle

lever does not seal the opening on the control handle,

unless the safety lever lock is intentionally folded down.

WARNING

Malfunctioning control handles can cause

unintentional actuation of a blast machine or

prevent a machine from deactivating upon

release. Malfunctioning control handles must

be taken out of service immediately and

repaired or replaced. Serious injury or death

could result from unintentional blasting.

3.2.12

Close the air valve on the compressor. Start the

compressor, and bring it to operating temperature and

pressure. The pressure must be more than 50 psi, but

must not exceed the blast machine’s rated pressure.

3.2.13

Slowly open the compressor air valve to

pressurize the air-supply line. Listen for open lines or air

leaks.

3.2.14

Load abrasive into the machine by following the

instructions in Section 3.8.

3.2.15

Do not allow anyone near the blast machine

except machine tenders who are appropriately attired in

approved personal protective equipment as noted in

Section 3.3.

WARNING

Everyone except for the blast operator or blast

machine tender must stay clear of the blast

machine. The machine tender or blast operator

may pressurize or depressurize the machine at

any time, which can cause abrasive to vent

under pressure, causing dust and toxins to

become airborne. Noise is produced by the

sudden release of compressed air when the

machine is pressurized or depressurized. These

conditions can cause injury. Both the operator

and machine tender must wear suitable

personal protective equipment including an

approved respirator, plus approved eye, face,

and hearing protection.

3.3 Blasting

Attire

WARNING

Before blasting, test the coating and substrate

for toxic materials, such as lead or other heavy

metals, or asbestos. These hazards require

special measures to protect the operators and

the environment.

Obtain a safety data sheet (SDS) for the blast

abrasive to identify hazardous substances.

Silica sand (crystalline) can cause silicosis,

lung cancer, and breathing problems in

exposed workers. Slag abrasives may contain

trace amounts of toxic metals

such as arsenic,

beryllium, and cadmium. Any abrasive dust has

potential to cause lung disease.

The lever lock must be folded down before the

control handle lever can be pressed.

Lever Lock

Prevents control handle lever

from being pressed down to the

blast position.

Control Handle Lever

Shown in the UP no-blast position.

Closed

Open