CLASSIC BLAST MACHINE with TLR-100/300 REMOTE CONTROLS

Page 13

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22501, Rev. I 02/18

Abrasive blasting operations can create high

levels of dust and noise. No dust is safe to

breathe. Abrasive blasting can produce harmful

dust. Failure to wear NIOSH-approved

respirators could result in serious lung disease

or death. The respirators must be properly fitted

and maintained NIOSH-approved, type-CE

supplied-air respirators approved for abrasive

blasting.

During abrasive blasting, abrasive particles and

dust in the area around the blast machine and

blast nozzle become airborne. Everyone

working in the vicinity of abrasive blasting must

wear properly maintained, NIOSH-approved,

respiratory protection and eye protection

appropriate for the job site hazards.

Loud noise generated by the use of

compressed air can cause hearing damage.

Everyone in the blasting area must wear

approved hearing protection.

It is the employer’s responsibility to train

employees to identify hazardous substances

and to provide suitable policies, procedures,

monitoring, recordkeeping, and personal

protective equipment.

3.3.1

Operators

and

anyone else who may be

exposed to the hazards generated by the blasting

process

must wear appropriate protective gear,

including abrasive-resistant clothing, leather gloves, eye

and hearing protection, and a NIOSH-approved type-CE

supplied-air respirator.

3.3.2

Don protective blasting attire outside the blast

area in a clean nonhazardous environment, free of

contaminants, where the air is safe to breathe.

3.3.3

When finished blasting and after cleanup is

completed, remove the respirator and protective clothing

outside the respirator-use area in a clean environment

where the air is safe to breathe.

3.4

Pressurize Blast Machine to Start Blasting

3.4.1

Don all protective blasting attire per Section 3.3.

3.4.2

When the blast operator is ready to blast, the

operator or the machine tender must close the safety

petcock. Closing the petcock prepares the machine for

remote operation and activation by the control handle.

Air should be heard escaping from the opening under

the control handle lever but from nowhere else. The air

escaping at the control handle is an audible signal

meaning air is supplied to the blast machine, which will

activate when the control handle is pressed.

3.4.3

Hold the blast hose securely and point the

nozzle only toward objects intended to be blasted.

3.4.4

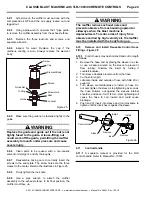

Fold down the safety lever lock and press the

remote control handle as shown in Figure 13. Within a

few seconds the pop-up valve will automatically close,

and the blast machine will pressurize to start blasting.

WARNING

Be prepared for the recoil from the blast hose.

Blasting should begin within a few seconds

after pressing the control handle lever.

Figure

13

WARNING

OSHA requires the use of remote controls on all

blast machines when an operator controls the

nozzle. To comply with OSHA regulations, the

remote control handle, which starts and stops

the flow of air and abrasive, must be held down

manually. Never tie down the control handle

lever or attempt to bypass any part of the remote

control system. Doing so will defeat the purpose

of the fail-to-safe feature of the remote control.

Serious injury or death could result from

uncontrolled blasting. Ref. 29 CFR 1910.244 (b).

3.4.5

If the abrasive metering valve is closed as

instructed, only air will exit the nozzle. Adjust abrasive

flow per Section 4.1.

Handle locked up

Fold lever lock down

Press control handle

down to begin blasting

Lever lock up