CLASSIC BLAST MACHINE with TLR-100/300 REMOTE CONTROLS

Page 16

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22501, Rev. I 02/18

3.9.6

When the machine is empty, release the control

handle lever, open the safety petcock, and open the

choke valve.

3.9.7

If the nozzle was removed, thoroughly inspect

the nozzle holder threads for wear before installing the

nozzle washer and reattaching the nozzle.

3.10 Shutdown

3.10.1

Empty the blast machine per Section 3.9.

3.10.2

When finished emptying the machine and after

cleanup is completed, remove the respirator and

protective clothing outside the respirator-use area, in a

clean environment where the air is safe to breathe.

3.10.3

Close the compressed-air supply valve at the

compressor.

3.10.4

Drain receiver tank, filters, air filters and water

collecting devices, and bleed the compressed-air supply

hose.

3.10.5

Shutdown the compressor.

3.10.6

Cover the blast machine when not in use. Refer

to Section 8.1 for optional cover.

4.0 ADJUSTMENTS

4.1

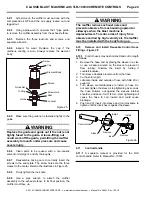

Adjust Abrasive Flow - Figure 16

The following instructions explain the adjustment of

handle-type FSV and LPV (Lo-Pot) metering valves.

Knob-type valves are adjusted by turning the knob

clockwise for less abrasive or counterclockwise for more

abrasive. Separate manuals are provided with alternate

valves.

4.1.1

Abrasive flow is adjusted at the metering valve

located at the bottom of the blast machine.

4.1.2

Begin adjustments with the metering valve

closed. The FSV and LPV metering valves are closed

when the handle is turned to either side of center until it

hits the stops. The alternate Quantum or MPV manual

pinch-tube metering valve is closed when the metering

knob is turned fully clockwise.

4.1.3

While the operator is blasting, the machine

tender increases abrasive flow by moving the handle

toward center no more than 1/4" at a time, allowing time

for the flow to stabilize before readjusting. The valve is

fully open when the handle is centered.

Figure

16

4.1.4

Optimum abrasive flow depends on the type and

size of abrasive and blasting pressure, and can best be

determined by experience. Use as little abrasive as

possible while maintaining the maximum cleaning rate.

The air-abrasive mixture should be mainly air. As a rule,

abrasive coming out of the nozzle should barely discolor

the air when seen against a contrasting background.

4.1.5

Once the correct flow is attained, loosen the

wing nut on the gauge unit and move the handle bolt

spacer against the metering handle. This helps to return

the setting to its original position when temporary

adjustments are required.

5.0 PREVENTIVE

MAINTENANCE

The following preventive maintenance instructions

pertain to the blast machine and remote controls only.

Read the owners manuals for the control handle and all

blast accessories, and for their inspection and

maintenance schedules.

5.1

Daily or More Frequent Inspection

5.1.1

With the air OFF before blasting, do the

following:

Empty the abrasive trap and clean the abrasive-trap

screen. Do this

at least twice a day

or more often if

the machine is frequently cycled. Failure to clean the

abrasive trap on a regular basis is a major cause of

system malfunction. Refer to Section 6.6.

Make sure couplings are secure and lock pins and

safety cables are in place.

Handle Bolt Spacer

Closed

Closed

Full Open