CLASSIC BLAST MACHINE with TLR-100/300 REMOTE CONTROLS

Page 17

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22501, Rev. I 02/18

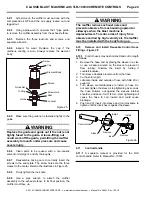

Inspect the RLX control handle; look for the following:

The control handle lever must not seal the opening

on the control unless the safety lever lock is folded

down.

The

handle lever

must return to the UP position

when released.

The

safety lever lock

must return to the UP

position when the handle lever is released.

Both the handle lever and safety lever lock must

move freely with no drag or binding.

WARNING

Malfunctioning control handles can cause

unintentional actuation of a blast machine, or

prevent a machine from deactivating upon

release. Malfunctioning control handles must

be taken out of service immediately and be

repaired or replaced. Serious injury or death

could result from unintentional blasting.

5.1.2

During blasting do the following:

Check the control handle for leaks.

Inspect all couplings and coupling gaskets for leaks.

Check the blast machine for leaks. If leaks are found

around the pop-up valve, inspection door,

pipefittings ports on the side of the machine or at the

bottom of the cone, stop blasting immediately and

repair or replace worn parts.

NOTICE

If leaks are allowed to continue, abrasive

erosion can cause extensive or irreparable

damage to the blast machine.

Check all external piping, control hoses, and valves

for leaks. If leaks are found, stop blasting and repair.

Inspect blast hose, couplings, and nozzle holders for

leaks. At the first sign of a leak, stop blasting and

repair or replace worn parts.

WARNING

Leaks around couplings and nozzle holders

indicate worn or loose-fitting parts. Nozzle

holders and couplings that do not fit tightly on

hose, and nozzles that do not fit tightly in nozzle

holders could disconnect while under pressure.

Impact from objects (nozzles, couplings, hoses,

or abrasive) disconnected by pressure during

operation can cause severe injury.

5.2 Weekly

Inspection

5.2.1

With the air OFF before blasting, do the

following:

Inspect the blast hose for wear; squeeze the hose

every three to four feet and look for soft spots. Soft

spots mean the hose is worn. Replace the blast hose

before the tube wears as far as the fabric plies.

WARNING

Worn blast hose could suddenly burst.

Couplings and nozzle holders may not

adequately grip worn hose, causing them to

blow off under pressure. Compressed air and

abrasive escaping from a burst hose, a

disconnected coupling, or a nozzle holder, can

cause severe injury.

Remove the nozzle for inspection. Replace with a

new nozzle if the orifice diameter is worn 1/16

or

more or if the liner is damaged.

Make sure the nozzle washer is in good condition

and in place before reattaching the nozzle.

WARNING

The threads on the nozzle and nozzle holder

must be inspected each time the nozzle is

secured to the holder. A loose-fitting nozzle

may eject under pressure and cause severe

injury. Check the threads for wear and make

sure the nozzle holder securely holds the

nozzle. The nozzle washer must also be

inspected for wear. When nozzle washers are

worn or missing, abrasive could erode nozzle

threads.

5.2.2

After blasting inspect the following:

Note the time it takes to fully depressurize the machine

after the control handle is released. When

depressurizing time increases noticeably, inspect the

abrasive trap per Section 6.6 and exhaust muffler per

Section 6.9.