CLASSIC BLAST MACHINE with TLR-100/300 REMOTE CONTROLS

Page 20

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22501, Rev. I 02/18

The large spring (not used in 1

valve) is

approximately 2-1/16

long. If it is rusty or

compressed, replace it.

Inspect the valve-plug washer, valve plug, and plug

retainer for damage. Replace all damaged parts.

When reassembling the valve-plug assembly, tighten

the retainer enough to compress the washer, but not

so tight that it causes it to bulge.

Look into the lower opening in the valve body. If the

machined seat is worn, replace the body.

Inspect the bottom cap seal and replace if damaged.

6.3.1.4

Remove the lower twinline hose connection and

remove the orifice fitting for inspection. Clean the 1/16

orifice and reassemble the connection.

WARNING

F

or proper operation, the orifice fitting must

always be in place. Do not modify it or

substitute another fitting. Altering the orifice

fitting may cause involuntary activation of the

blast machine or some other malfunction, which

could result in serious injury or death.

6.3.1.5

If the top section of the valve requires service,

proceed to Section 6.3.2; otherwise, refer to the

illustration in Figure 17 to reassemble the valve in

reverse order.

6.3.2

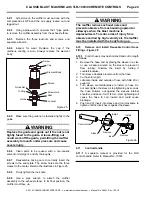

Top Section - Figure 18

6.3.2.1

Remove the control hose and fittings from the

cylinder cap to make sure they are not damaged by a

wrench.

6.3.2.2

Use a pipe wrench to remove the cylinder cap.

6.3.2.3

If the bottom cap has not been removed, remove

the cap and all parts in the bottom section per Section

6.3.1.

6.3.2.4

Insert a wooden hammer handle or similar

object into the bottom of the valve body, push through

the seat area and drive the piston rod up. Doing so will

push the piston out the top of the valve body.

6.3.2.5

Inspect all items for wear and damage:

The piston cup should fit snugly against the cylinder

wall. If it does not, replace the piston assembly.

The piston rod should be free of deep abrasion and

move freely in the rod’s bore. If it is badly abraded,

drags in the bore, or is loose in the bore, replace the

piston assembly.

If the piston rod O-ring is flattened, replace the O-ring.

Inspect the cylinder cap O-ring. Replace it if it is cut

or if it does not fit snugly into the recess at the end of

the threads.

*Items included in service kits.

Figure

18

6.3.2.6

Lubricate the cylinder wall and piston cup with

lightweight machine oil or tool oil.

6.3.2.7

Install the piston into the cylinder. As the piston

cup contacts the cylinder, it may be difficult to press into

place. Do not pound the piston, as that could damage

the cup; make sure the lower lip of the cup does not curl

in or get cut. Rotating the piston while applying thumb

pressure makes assembly easier.

6.3.2.8

Refer to the illustration in Figures 17 and 18 to

reassemble the valve in reverse order.

6.4

Piston Outlet Valve - Figure 19

Refer to Section 6.5 to service the diaphragm outlet valve.

6.4.1

All service on the outlet valve must be done with

the air OFF and the air supply locked out and tagged

out. It is not necessary to remove the valve from the

blast machine.

6.4.2

Remove the control hose from the valve

bonnet’s elbow adaptor. NOTE: The elbow adaptor and

plug do not need to be removed unless they need to be

replaced.

6.4.3

Using a large wrench, loosen the bonnet from

the valve body until it can be removed by hand.

Elbow Adaptor

Safety Petcock

Does not need to

be removed unless

it is to be replaced.

*Cylinder Cap O-Ring

Cylinder Cap

*Piston Rod O-Ring

Piston Cup

Piston Rod

For replacement parts refer

to Sections

8.9 for 1-1/2" inlet valve and

8.10 for 1" inlet valve.

Piston Assembly

Elbow Adaptor