CLASSIC BLAST MACHINE with TLR-100/300 REMOTE CONTROLS

Page 25

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22501, Rev. I 02/18

7.0 TROUBLESHOOTING

NOTE:

This section only identifies conditions and

problems in the blast machine and remote control

system. Always refer to the appropriate section of this

manual or manuals for accessory equipment when

troubleshooting and before servicing the equipment. A

separate manual is provided for the RLX control handle.

WARNING

To avoid serious injury, observe the following

when troubleshooting the machine and remote

controls;

Turn OFF the compressed air, and lockout and

tagout the air supply.

When checking controls require air, always

enlist the aid of another person to operate the

control handle while holding the nozzle securely

and pointing it in a safe direction.

Never strap the remote control handle lever

down in the operating position.

7.1

Neither Abrasive nor Air Exits Nozzle While

Machine is Under Pressure

7.1.1

Nozzle may be obstructed. Depressurize the

blast machine. After the pop-up valve has dropped,

remove the nozzle and check it for obstruction.

7.1.2

Valves maybe closed. Make sure both the

abrasive metering valve and choke valve are open.

7.2

Air Only (No Abrasive) Exits Nozzle

7.2.1

Abrasive metering valve may be closed or

needs adjustment. Adjust abrasive flow per Section 4.1.

7.2.2

Blast machine may be empty.

7.2.3

Abrasive may be damp. Refer to Section 6.1 to

clear damp abrasive.

7.2.4

Check the abrasive

metering valve for

obstructions per Section 6.2.

7.3

Heavy Abrasive Flow

7.3.1

Make sure the choke valve is open. The valve is

open when the handle is inline with the piping.

7.3.2

Abrasive metering valve may be open too far.

Adjust abrasive flow per Section 4.1.

7.4 Abrasive

Surging

7.4.1

A moderate amount of abrasive

surge is normal

at startup. Should the flow of abrasive continue to surge,

reduce the amount of abrasive

in the air stream by

adjusting the metering valve. Adjust abrasive flow per

Section 4.1.

7.4.2

Check the abrasive trap and exhaust muffler for

blockage. Slow depressurization will load the blast hose

with abrasive and cause surging at startup.

7.4.3

Blast machine may be depressurizing too slowly,

forcing abrasive into the blast hose. Refer to Section 7.6.

7.5

Intermittent Abrasive Flow

7.5.1

Moisture in the blast machine or in the air

supply. Drain moisture from the compressor's receiver

tank and if so equipped, the blast machine's air filter. If

problem with moisture persists, an aftercooler or air

dryer may be required.

7.5.2

Abrasive may be too fine or worn from recycling.

Replace abrasive.

7.6

Blast Machine Does Not Pressurize

7.6.1

Make sure the compressor is ON and all air-

supply valves to the machine are open.

7.6.2

Make sure the safety petcock on the inlet valve

is closed.

7.6.3

Inspect the rubber button on the control handle

for wear or damage; make sure it seals the opening in

the handle when the lever is pressed.

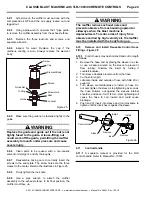

7.6.4

While the control handle lever is up, check for

air escaping (from under the lever) through the opening

in the handle. If no air escapes, the orifice on the inlet

valve, shown enlarged in Figure 2, is blocked or the line

from the orifice to the control handle is blocked and must

be cleared.

7.6.5

Press the control handle lever. Feel for and

listen for air leaks anyplace on the handle. If there is a

leak, it must be located and repaired. The RLX control

handle is covered in Manual No. 10574.

7.6.6

Press the control handle lever and check control

lines and fittings for air leaks. Once the control handle is

pressed, there should be no air leaking from anyplace in

the controls or blast machine. Any air leak must be

located and serviced.