CLASSIC BLAST MACHINE with TLR-100/300 REMOTE CONTROLS

Page 8

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22501, Rev. I 02/18

the minimum recommended hose size based on the

nozzle orifice size. A smaller diameter hose could result

in a reduction in nozzle pressure.

AIR LINE RECOMMENDATIONS

BASED ON NOZZLE SIZE

Nozzle

Orifice Size

Recommended Air Supply Line

No. 3, 3/16"

3/4" ID or larger

No. 4, 1/4"

1" ID or larger

No. 5, 5/16"

1-1/4" ID or larger

No. 6, 3/8"

1-1/2" ID or larger

No. 7, 7/16"

2" ID or larger

No. 8, 1/4"

2" ID or larger

Refer to the compressed-air and abrasive

consumption table in Figure 10 for approximate air

consumption.

Figure

6

2.6

Blast Hose and Remote Control Hose

Connections

NOTE: When installing the optional ACS feature,

refer to Section 2.7 for additional instructions.

WARNING

Where two or more blast machines are used in

close proximity, care must be taken when

tracing and connecting control lines and blast

hose. Cross connecting control hose or blast

hose could lead to serious injury, death, or

property damage from unintentional actuation

of a blast machine. To prevent cross

connecting blast hose and control hose, the

hoses should be of equal lengths and the hoses

and blast machine couplings clearly marked,

using optional hose identification kits, stock no.

15890 for use with two blast machines, or stock

no. 15891 for up to four machines. Mark each

hose and corresponding connection per the

instructions supplied with the kit and carefully

trace and verify each connection before

operating.

WARNING

Moist air that freezes can cause blockage at the

control handle or in the control lines. Blockage

can cause involuntary activation of the remote

controls or prevent the controls from

deactivating upon release of the control handle.

This situation could result in serious injury or

death. If remote controls are operated in

freezing or near-freezing weather, install a

Clemco Antifreeze Injector, stock no. 05537, on

the remote control air-supply line.

NOTE: Control hoses come with reusable hose ends.

Excess hose may be cut-to-fit and recoupled; refer to

Section 6.10.

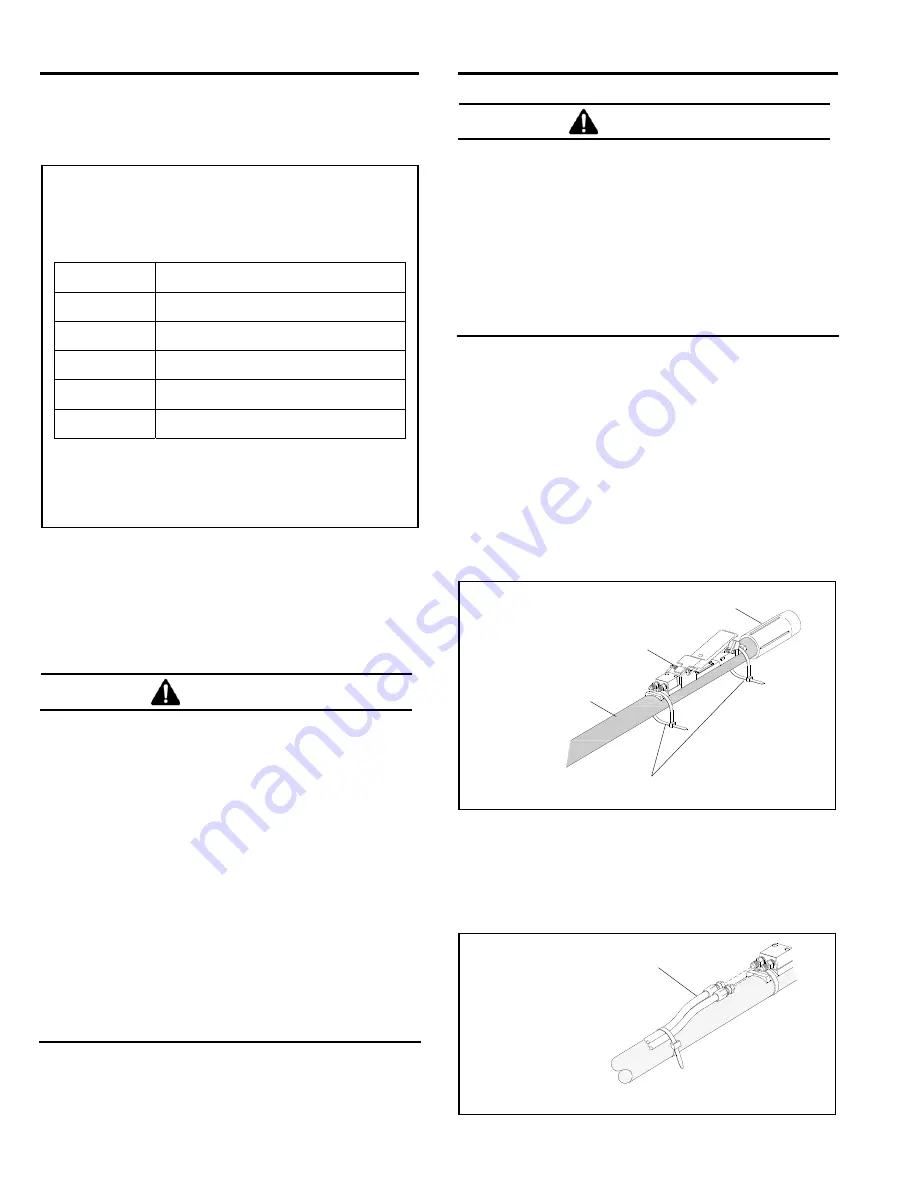

2.6.1

Uncoil the blast hose and lay the 50-foot twinline

hose alongside it.

2.6.2

Band the control handle to the blast hose close

to the nozzle holder, as shown in Figure 7, using the two

nylon ties provided. After the control is firmly attached,

clip the tie ends to avoid snags or interference with the

operation of the control handle.

Figure

7

2.6.3

Attach the 50-foot twinline hose to the two

fittings on the control handle, as shown in Figure 8.

Either side of the hose can be attached to either fitting.

When using the ACS option, attach the single-line hose

noted in Section 2.7.

Figure

8

RLX Control Handle

Nozzle Holder

Blast Hose

Nylon Ties

Twinline Control Hose

Either side of the twinline

can attach to either fitting

on the control handle.