MEDIPULSE 2342se ERGONOMIC SUCTION BLAST CABINET

Page 13

© 2019

CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 24939, Rev. C, 03/19

(counterclockwise when viewed from the top) until the

media flows smoothly. Tighten the lock nut finger-tight to

maintain the setting.

5.3.4

If media flow is too light, decrease air in the

mixture by turning the metering screw in (clockwise

when viewed from the top) covering more of the holes so

less air enters the media hose. Tighten the lock nut

finger-tight to maintain the setting.

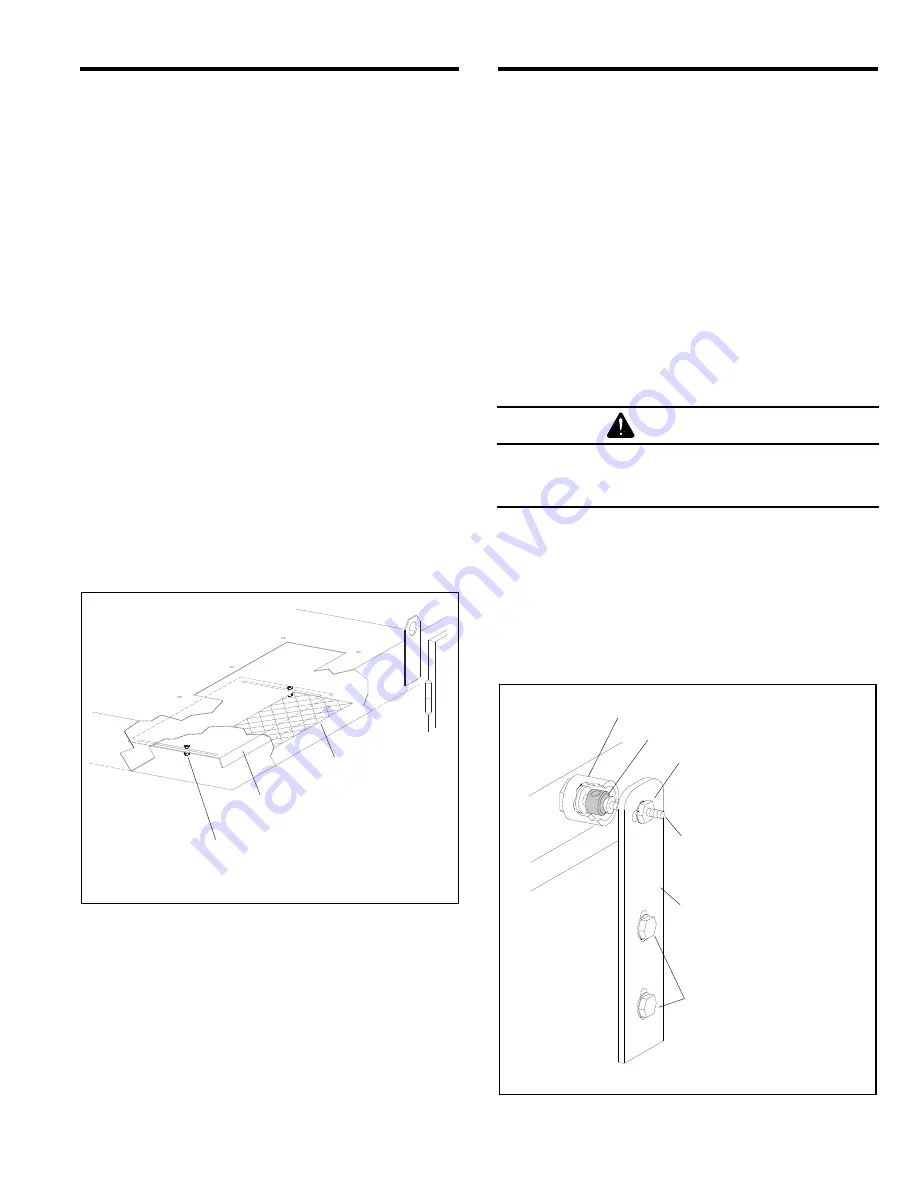

5.4

Reclaimer Static Pressure

5.4.1

Correct static pressure varies with the size,

weight, and type of media.

5.4.2

Adjust static pressure by opening or closing the

outlet damper located above the reclaimer on the

underside of the underside of the power module top, as

shown in Figure 17. If the damper is not opened far

enough, the reclaimer will not remove fines, resulting in

dusty media and poor visibility, or will not convey media,

causing media buildup in the hose between the cabinet

hopper and reclaimer. If the damper is opened too far, it

may cause carry over (usable media carried into the dust

collector) and result in excessive media consumption.

Open only as far as necessary to obtain a balance of

maximum dust removal without media carry over.

Figure 17

5.4.3

A manometer is useful for adjusting and

monitoring static pressure. The manometer kit is listed in

Section 9.1: Optional Accessories

. Refer to Section 5.8

for manometer operations. The following are static-

pressure starting points for given media. Static pressure

may need to be lower with finer media, higher with

coarser media. Run the media through several blast

cycles, allowing the reclaimer to function with these

settings. Inspect media in the reclaimer and fines in the

dust collector, as noted in Paragraph 5.4.2. Continue

adjusting static pressure until optimum media cleaning

without carry over is attained.

Glass Bead No. 6 and 7 ................................. 3-1/2" – 4"

Glass Bead No. 8 to 12 .................................. 3" – 3-1/2"

Aluminum Oxide 60-Mesh to 80-Mesh .................. 4" – 5"

Aluminum Oxide 80-Mesh to 180-Mesh ................ 3" – 4"

5.4.4

As dust accumulates on the outer surface of the

cartridge, static pressure drops, requiring additional

pulsing of the cartridge as described in Section 6.2.4, or

an increase in pulse pressure, per Section 5.6. When

pulsing no longer maintains the necessary static

pressure, readjust the damper.

5.5

Door Interlocks ‒ Figure 18

WARNING

Never bypass the door interlock system. Doing

so can result in serious injury from unexpected

blasting.

5.5.1

The door interlocks disable the blasting control

circuit when doors are open. To enable blasting, the

door-interlock switches must be engaged when doors

are closed. The interlocks are set at the factory and do

not normally require field adjustment unless parts are

replaced. If adjustment is required, proceed as follows.

5.5.2

Close cabinet doors.

Figure 18

To adjust opening, loosen nuts

and slide damper. Tighten nuts

to maintain the setting.

Outlet Damper

Screen

Cabinet Door

Detent Sleeve

Over-Travel Stop

Loosen nut and move adjusting

screw sideways to center the

screw on the over-travel stop.

Adjusting Screw Nut

Loosen the bracket screws and

move the bracket up or down to

center the adjusting screw on the

over-travel stop.

Actuator Adjusting Bracket

Bracket Screws

Adjust the screw to push the

valve stem (over-travel stop)

in when door is closed.

Adjusting Screw