MEDIPULSE 2342se ERGONOMIC SUCTION BLAST CABINET

Page 2

© 2019

CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 24939, Rev. C, 03/19

Cabinet Air-Inlet Damper ............................................ 5.7

Optional Manometer ................................................... 5.8

Foot Shelf ................................................................... 5.9

PREVENTIVE MAINTENANCE ................................. 6.0

Daily Inspection and Maintenance Before Blasting .... 6.1

Check media level ................................................ 6.1.1

Inspect reclaimer debris screen and door gasket ... 6.1.2

Drain compressed-air filter ................................... 6.1.3

Inspect dust container .......................................... 6.1.4

Daily Inspection During Blasting ................................ 6.2

Inspect cabinet for dust leaks .............................. 6.2.1

Check exhaust air for dust ................................... 6.2.2

Drain pulse reservoir ............................................ 6.2.3

Additional cartridge pulsing .................................. 6.2.4

Weekly Inspection and Maintenance Before Blasting ... 6.3

Inspect view-window cover lens .......................... 6.3.1

Inspect gloves ...................................................... 6.3.2

Inspect BNP

®

gun assembly ................................ 6.3.3

Inspect media hose .............................................. 6.3.4

Weekly Inspection During Blasting ............................ 6.4

Inspect flex hoses ................................................. 6.4.1

SERVICE MAINTENANCE ......................................... 7.0

Gloves ......................................................................... 7.1

BNP

®

Gun Assembly ................................................... 7.2

View-Window Cover Lens ........................................... 7.3

View-Window Replacement ........................................ 7.4

Window-Gasket Replacement ..................................... 7.5

Window-Frame Removal ............................................. 7.6

LED Light Assembly .................................................... 7.7

Replacing Reclaimer Wear Plate ................................ 7.8

Replacing Filter Cartridge ........................................... 7.9

Seasoning Filter Cartridge ........................................ 7.10

TROUBLESHOOTING ................................................ 8.0

Poor visibility ............................................................... 8.1

Abnormally high media consumption .......................... 8.2

Reduction in blast cleaning rate .................................. 8.3

Plugged nozzle ............................................................. 8.4

Media bridging .............................................................. 8.5

Media surge ................................................................. 8.6

Blockage in media hose .............................................. 8.7

Poor suction in media hose ......................................... 8.8

Air only (no media) from nozzle ................................... 8.9

Blow-back through media hose ................................. 8.10

Blasting does not begin when the foot pedal is pressed . 8.11

Blasting continues after releasing foot pedal ............. 8.12

Media buildup in cabinet hopper ............................... 8.13

Static shocks ............................................................. 8.14

Dust leaking from cabinet .......................................... 8.15

Dust leaking from dust collector ................................ 8.16

Dust collector does not pulse when foot pedal

is pressed or released ............................................ 8.17

A steady stream of air is heard within the dust

collector when the foot pedal is not pressed ....... 8.18

ACCESSORIES AND REPLACEMENT PARTS ....... 9.0

Optional Accessories (field installed) .......................... 9.1

BNP

®

Gun and Feed Assembly ................................... 9.2

Cabinet Assembly ....................................................... 9.3

LED Light Assembly .................................................... 9.4

View Window ............................................................... 9.5

Metering Valve ............................................................ 9.6

Foot Pedal ................................................................... 9.7

Filter-Regulator Inlet Piping Assembly ........................ 9.8

Cabinet Controls and Plumbing .................................. 9.9

Reclaimer, 300 cfm ................................................... 9.10

Dust Collector, 300 cfm ............................................. 9.11

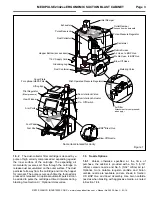

1.4

General Description

1.4.1

Refer to Figure 1 for arrangement of

components. The MediPulse cabinet encloses the

blasting environment to provide efficient blasting while

maintaining a clean surrounding work area. Production

rates are influenced by size of air jet and nozzle,

compressor output, working pressure, type and size of

media, and angle and distance of the nozzle from the

blast surface. MediPulse 2342se cabinet consists of two

major components.

1. Cabinet Enclosure

2. Power Module

1.4.2 Cabinet enclosure

Approximate work chamber dimensions:

42" wide x 23" deep x 30" high.

1.4.3 Power module:

300 CFM Power Module is attached to the back of the

cabinet enclosure and includes:

• 300 cfm reclaimer

• 300 cfm reverse-pulse cartridge dust collector

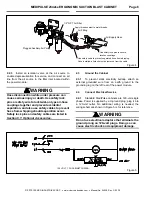

1.5

Theory of Operation

1.5.1

Once the cabinet is correctly set up and turned on,

the cabinet is then ready for operation by actuation of the

foot pedal. Fully depressing down on the foot pedal causes

air to flow through the blast gun. The partial vacuum

created by air moving through the gun draws media into

the blast-gun mixing chamber. The media mixes with the

air stream and is propelled out the nozzle. After striking the

object being blasted, the blast media, fines, dust, and

byproducts generated by blasting fall through the grate into

the cabinet hoppers. These particles are then drawn into

the reclaimer for separation. Dust and fines are first

separated from reusable media and pass into the dust

collector. Next, the media is screened for oversize particles

and returned to the reclaimer hopper for reuse. Dust and

fines entering the dust collector are removed from the air

stream as they pass through the filter, discharging clean

air. When the foot pedal is released, blasting stops.