MEDIPULSE 2342se ERGONOMIC SUCTION BLAST CABINET

Page 8

© 2019

CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 24939, Rev. C, 03/19

right side or left side door. The right side is shown in the

illustrations.

3.3.2

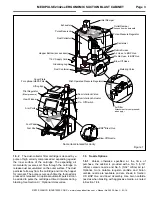

Combine the table assembly and track by sliding

the table assembly rollers into the track channels, as

shown in Figure 7.

NOTE: If the weight of the table and track make it too

heavy to install as an assembly, the track may be placed

in the cabinet to predrill mounting holes, but the table

must also be in place within the rails before fasteners

are installed.

3.3.3

Refer to Figure 8 and center the track and table

assembly inside the cabinet on top of the grate. Make

sure the two angled mounting brackets are facing toward

the door from which the table will slide.

Figure 8

3.3.4

Match drill two 1/2" diameter holes on each side

of the cabinet, using the holes in the mounting brackets

as a template. NOTE: To prevent the track from shifting,

temporarily place a 3/8-NC x 1-1/2" bolt through each

hole after it is drilled.

3.3.5

After the holes are drilled and the table

assembly is placed in the track rails, secure all

fasteners.

Figure 9

3.4

Manometer

The optional manometer kit is listed in Section 9.1.

3.4.1

The manometer measures static pressure.

Consistent static pressure is necessary for precise

media separation, as the reclaimer's efficiency is

achieved by a centrifugal balance of air flow, particle

weight, and size. Reclaimer static pressure is set by

adjusting the outlet damper; refer to Section 5.4 to adjust

static pressure. Refer to Section 5.8 for manometer

instructions.

3.5

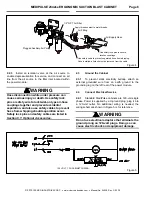

Reclaimer Differential Pressure Gauge

Monitors reclaimer static pressure ‒ Figure 10

3.5.1

The reclaimer differential pressure gauge

continually measures reclaimer static pressure, similar to

a manometer slack tube but it uses a differential

pressure gauge.

3.5.2

The gauge panel, gauge, filter, and panel fittings

come fully assembled; the bushings, snubber fittings,

and tubing are loose. Mount the panel at a location

where it can be easily monitored. A 10-foot length of

tubing is included with the kit, allowing the panel to be

mounted within ten feet of the connections. One

suggestion is to mount it on an accessible side of the

power module.

3.5.3

Mounting holes are on the left and right sides of

the gauge panel. After selecting the location, match drill

holes, and use nuts and cap screws to secure the panel.

3.5.4

Remove the 1/4" pipe plug from the reclaimer

body and install 1/4" x 1/8" bushing and barb fitting, as

shown in Figure 10.

Figure 10

3.5.5

Push the tubing onto the barb fittings on the

gauge and reclaimer, as shown. Cut the tubing to length.

3.5.6

Refer to the differential pressure gauge manual

provided for operation of the gauge.

Urethane Tubing

Differential

Pressure Gauge

Remove plug and install

bushing and barb fitting.

Slide table to center or as

needed to position part for

blasting.

Slide table out for ease

of loading part(s). Not

to exceed 500 pounds.

Match Drill

Match Drill

Angled Mount Brackets