PIPE-PRO XL™ INTERNAL-PIPE BLAST TOOL

Page 13

© 2017 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 27804 Rev A

coupling-flange are shown in the preventive

maintenance section. Refer to Section 7.3.1 to service

the blast head assembly and Section 7.3.2 to service the

backplate coupling-flange assembly.

NOTICE

Removed the tool from the blast hose or lance

and service it in a clean, abrasive-free and dust-

free environment.

Remove the tool from the carriage collar before

performing any service other than the blast

head and nozzles.

8.1

Carriage

8.1.1

Removing the carriage

8.1.1.1

Completely remove the three cap screws

holding the carriage collar to the drive cap and then slide

the carriage from the base tool. Note: If lodged abrasive

prevents removal from the carriage, pry the pieces apart

at the seam between the drive cap and carriage collar

flange, or place a wooden block or similar object against

the quick coupling and rap the block with a hammer to

remove the tool.

8.1.2

Attaching the carriage

8.1.2.1

Insert the base tool, quick coupling first into the

flanged end of the carriage.

8.1.2.2

Align the bolt holes in the drive cap with those in

the carriage collar and insert the plate into the flange.

Align the holes as needed and install the three flat

washers, lock washers, and cap screws to secure.

8.2

Blast Head Assembly, Removal and Inspection

8.2.1

Remove the blast head per Section 7.3.1 and

service the head assembly as needed. Do not yet

reassemble the blast head unless no further service is

required.

8.3 Backplate Coupling Flange Assembly

Removal and Inspection

8.3.1

Remove the backplate coupling flange per

Section 7.3.2 and service the head assembly as needed.

8.3.2

The rear-seals cartridge (sleeve with u-seals and

spacer) may slide out without pressing it. If it slides out,

remove it now; if it does not slide, it will be pressed out

later in Section 8.6. Do not yet reassemble the backplate

and coupling flange unless no further service is required.

8.4

Front Housing and Bearing Removal and

Inspection

8.4.1

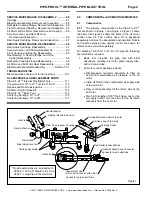

Refer to Figure 22 and unscrew the lock nut

from the axle.

8.4.2

Refer to the following caution and use a 4 mm

hex key to remove the six socket head screws to

separate the front housing from the drive cap and slide

the housing off the axle.

CAUTION

The housing is under moderate spring

pressure. When the retaining screws are

removed, the spring will force the housing

about 1-1/2 inches from the drive cap.

Figure

22

8.4.3

Remove spring bushing and spring from the axle.

8.4.4

Inspect the rim on the head (bearing) side of

spring bushing. When new, the rim extends about 1/16"

from the flange. If the rim is worn beyond 1/32", replace

the bushing.

8.4.5

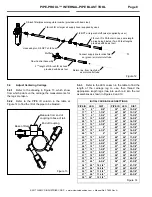

Refer to Figure 23 and remove the felt seal from

the front housing.

Figure

23

8.4.6

Refer to Figure 24 and remove the bearing from

the front housing; the bearing fits snugly in the housing, if

Axle

Spring Bushing

Spring

Felt Seal

Front Housing

Drive Cap

Socket Head Screw

Front Housing

Lock Nut

Axle