PIPE-PRO XL™ INTERNAL-PIPE BLAST TOOL

Page 14

© 2017 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 27804 Rev A

required, use a puller to remove the bearing. Note: if the

bearing stays on the axle, it will be removed later as

noted in Paragraph 8.6.5.

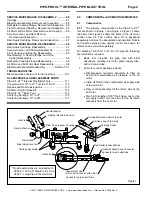

Figure

24

8.4.7

Wipe the bearing clean and turn the races; the

races should turn smoothly. Replace the bearing if it

feels gritty when turning it.

8.4.8

Inspect the inside of the housing:

If no dust is present, replace only the felt seal.

If dust is present on only the head side of the bearing,

replace the felt seal and the u-seal.

If dust is present on the inward side of the bearing,

axle and axle-gear, service the axle per Section 8.6

8.4.9

If the gears are totally dust free, apply a liberal

amount of Mobilgrease XHP 462 Moly, Chevron Delo

Heavy Duty Moly 3% EP 2, or equivalent gear grease to

the gear teeth, and reassemble the bearing and housing

per Section 9.3.

8.4.10

If no additional service is required, reassemble

the tool per Section 9.0.

8.5

Air Motor and Air Motor Gear Removal and

Inspection. Refer to Figure 25

NOTE: Removing the air motor requires a narrow 33

millimeter wrench or an adjustable wrench narrow enough

to fit within the confines of the air motor’s flats. If a wrench

is not available, one should be purchased, or machine (or

grind) one until it is narrow enough to fit within the flats.

Remove the air motor for protection and inspection before

removing the axle or drive cap.

NOTICE

Do not use a pipe wrench or similar tool to

remove the air motor; doing so will damage the

motor.

8.5.1

The air motor has left-handed or reverse

threads; to remove the motor from the drive cap, turn the

motor clockwise as shown in Figure 25.

Figure

25

8.5.2

Inspect the gear; there is no need to separate

the gear from the motor if neither is being replaced. If

service or replacement is needed, use a 2-mm hex key

to remove the gear.

8.5.3

It is not necessary to remove the 1/8 x 8 mm

inlet tube adaptor, 1/4 x 8 mm outlet tube adaptor, or

tubing from the air motor unless either requires

replacement or the air motor needs service. When

required, remove the adaptors by unscrewing them.

NOTICE

To reduce the risk of abrasive or foreign

material contamination into the air motor, cover

air motor fittings, ports, or tubing. Any foreign

material entering the air motor will cause the air

motor to fail. Motor failure from ingress of dust,

abrasive, or foreign matter voids the warranty.

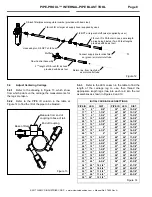

8.6

Axle, Axle Gear, and Rear Bearing Removal

and Inspection

8.6.1

Occasionally the axle can be removed from the

tube casing by sliding the axle back and forth as you

would a slide puller. If the axle cannot be removed as

noted, it can be pressed out, as follows.

8.6.2

Support the drive cap and tube casing in the

press as shown in Figure 26. Make sure the supports do

not block the axle.

Air motor and gear removed

from the drive cap.

Wrench Flats

Turn air motor

clockwise to remove.

Drive Cap

Bearing

Back side of Front Housing

U-Seal, open side

toward bearing