PIPE-PRO XL™ INTERNAL-PIPE BLAST TOOL

Page 17

© 2017 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 27804 Rev A

NOTICE

If the housing makes hard contact before it is

close enough for the screws to engage, do not

force it; internal parts are not aligned. Release

and reapply pressure until the housing slides

into position so it can be secured with screws.

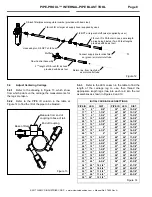

9.3.8

Observe the gap between the bearing housing

and tighten the screws in unison until the flange on the

housing just begins to enter the drive cap. At that time

tighten each screw about half a turn at a time, the

screws should easily turn. If a screw becomes tight,

move to another until the housing is fully seated into the

drive cap.

Figure

32

9.3.9

After the housing is seated in the drive cap,

tighten all screws to secure.

9.4

Rear Bearing, U-Seal Cartridge, and Tube

Casing Reassembly

9.4.1

Place the assembled tool on a bench with the

rear of the tube casing facing up as shown in Figure 33.

9.4.2

Fully insert the rear bearing into the end of the

tube casing. Pressing the bearing is usually not needed

if the bearing is inserted straight with no side-cocking.

Figure

33

9.4.3

Insert the u-seal cartridge into the tube casing.

The side of the cartridge with the open u-seal faces up.

9.5 Backplate Coupling-Flange Reassembly,

Figure 34

9.5.1

Place the plastic seal-disc into the tube casing.

Note: If the disc is to be reused, make sure the grooved

side faces toward the axle. If the disc is new the sides

are identical; it does not matter how it is installed. The

groove will be formed by the rotating axle.

9.5.2

Place the backplate atop the disc and uniformly

tighten the screws to secure. Note: If the end of the axle

extends too far out to prevent installation of the screws,

remove the disc, place a folded paper towel or similar

protective cover over the ridge on the axle, and tighten

the backplate enough to press the axle into the tube

casing. Remove the backplate and protective cover and

reassemble with the seal-disc in place.

Figure

34

9.6

Air Motor and Air Motor Gear Reassembly,

Refer to Figure 35

NOTE: Installation of the air motor requires a narrow 33-

millimeter wrench. If a wrench is not available, one

should be purchased, or machine (or grind) one until it is

narrow enough to fit within the flats.

9.6.1

If the gear was removed or replaced, install it

onto the motor shaft with the set screw end facing

toward the motor as shown in Figure 35. Slide it fully

onto the shaft leaving only enough room to insert a 2-mm

hex key into the set screw. Tighten the screw to secure.

9.6.2

Apply a generous amount of Mobilgrease XHP

462 Moly, Chevron Delo Heavy Duty Moly 3% EP 2, or

equivalent gear grease to the gear teeth, and gear

socket in the drive cap.

Front Bearing Housing

Apply downward pressure on the

bearing housing to start at least

two screws into the drive cap.

Drive Cap

Bearing and Cartridge

Installed in Tube

Assembled U-Seal Cartridge

The open side of u-seal faces up

Bearing

Tube

Backplate with Coupling

Plastic Seal-Disc

Tube Casing