PIPE-PRO XL™ INTERNAL-PIPE BLAST TOOL

Page 1

© 2017 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 27804 Rev A

1.0 INTRODUCTION

1.1

Scope of Manual

1.1.1

These instructions cover set-up, operation,

maintenance, troubleshooting, and replacement parts for

Clemco’s Pipe-Pro XL

TM

internal pipe blasting tool.

1.1.2

These instructions contain important safety

information. All operators and personnel involved with

the abrasive blast process must read and understand

the contents of these instructions, including the orange

cover. It is equally important that the operator is trained

and qualified to safely operate the blast machine, remote

controls, and all other equipment used with the blast

machine.

1.1.3

All personnel involved with the abrasive blasting

process must be made aware of the hazards associated

with abrasive blasting. The Clemco booklet

Abrasive

Blasting Safety Practices

is included with every blast

machine, and contains important safety information

about abrasive blasting that may not be included in

equipment operation manuals. To order additional

copies, visit

www.clemcoindustries.com

or email

info@clemcoindustries.com

.

1.2 Safety

Alerts

1.2.1

Clemco uses safety alert signal words, based on

ANSI Z535.4-2011, to alert the user of a potentially

hazardous situation that may be encountered while

operating this equipment. ANSI's definitions of the signal

words are as follows:

This is the safety alert symbol. It is

used to alert you to potential physical

injury hazards. Obey all safety

messages that follow this symbol to

avoid possible injury or death.

NOTICE

Notice indicates information that is considered

important, but not hazard-related, if not

avoided, could result in property damage.

CAUTION

Caution indicates a hazardous situation that, if

not avoided, could result in minor or moderate

injury.

WARNING

Warning indicates a hazardous situation that, if

not avoided, could result in death or serious

injury.

DANGER

Danger indicates a hazardous situation that, if

not avoided, will result in death or serious

injury.

1.3

Table of Contents

SUBJECT SECTION

LOCATION

INTRODUCTION ........................................................ 1.0

Scope of Manual ........................................................ 1.1

Safety Alerts ............................................................... 1.2

Table of Contents ....................................................... 1.3

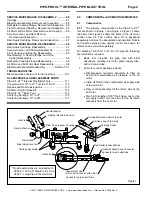

COMPONENTS and OPERATING PRINCIPLES ..... 2.0

Components ................................................................ 2.1

Operating Principles .................................................... 2.2

ANCILLARY EQUIPMENT REQUIREMENTS ........... 3.0

Blast Machine and Accessories .................................. 3.1

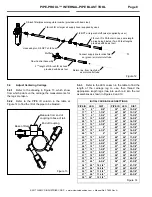

Nozzle Stand-Off Distance Tables .............................. 3.2

For 16" to 31" Pipe ................................................ 3.2.1

For 32" to 60" Pipe ................................................ 3.2.2

Pipe Lance .................................................................. 3.3

Air Motor Air-Requirements ......................................... 3.4

Compressed Air Requirements ................................... 3.5

Ambient Temperature Range Limits ........................... 3.6

ABRASIVES ............................................................... 4.0

SET-UP ....................................................................... 5.0

Staging Platform .......................................................... 5.1

Assemble Centering Carriage ..................................... 5.2

16" to 31" carriage ................................................ 5.2.1

32" to 60" carriage extensions .............................. 5.2.2

Air Motor Connections ................................................. 5.3

Adjust Centering Carriage ........................................... 5.4

Attach Nozzles and Nozzle Extensions ...................... 5.5

Connect Blast Hose and Lance ................................... 5.6

OPERATION ............................................................... 6.0

Set Motor Speed ......................................................... 6.3

PREVENTIVE MAINTENANCE .................................. 7.0

Air Motor Air-Supply Line ............................................. 7.1

8-Hour Inspection ........................................................ 7.2

Nozzles and nozzle extensions ............................. 7.2.1

16-Hour Inspection ...................................................... 7.3

Blast head assembly .............................................. 7.3.1

Backplate coupling-flange ..................................... 7.3.2

30-Hour Inspection ...................................................... 7.4

Every Three Months and Before Long Term Storage . 7.5

Air Motor Service ......................................................... 7.6