PIPE-PRO XL™ INTERNAL-PIPE BLAST TOOL

Page 4

© 2017 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 27804 Rev A

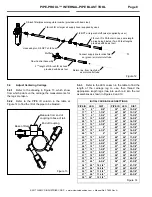

3.2

Nozzle Stand-Off-Distance Tables

The stand-off distance is the distance from the exit end

of the nozzle to the inside surface (diameter) of the pipe.

3.2.1

For 16" to 31" Pipe

3.2.1.1

The table in Figure 4 shows the approximate

stand-off distances of short and long venturi nozzles

when blasting pipe diameters between 16" and 31".

3.2.2

For 32" to 60" Pipe

3.2.2.1

The table in Figure 5 is a quick view of

approximate stand-off distance for nozzles and nozzle

extensions when blasting 32" to 60" pipe. When more

precision is needed refer to Figure 6 to calculate nozzle

stand-off distances.

3.2.3

The nozzles and stand-off distances shown are

only guidelines to assist the user in choosing nozzle type

and orifice diameter; it does not show the nozzle to use

with a given pipe diameter. Usually the minimum stand-

off distance is about four inches; maximum distance is

generally between 8" and 16" but depends on nozzle

orifice size (usually determined by the volume of

compressed air available), nozzle pressure, surface

condition, and degree of cleaning required.

NOZZLE STAND-OFF-DISTANCE

FOR 16" to 31" ID PIPE

PIPE

SHORT

LONG VENTURI NOZZLE

INSIDE VENTURI

1/4"

5/16" 3/8"

DIAMETER NOZZLE Orifice

Orifice

Orifice

16" 3-3/4"

1-3/4"

1-1/4"

N/A

17" 4-1/4"

2-1/4" 1-3/"4 3/4"

18" 4-3/4"

2-3/4" 2-1/4" 1-1/4"

19" 5-1/2"

3-1/4"

3"

2"

20" 6"

4"

3-1/2"

2-1/2"

21" 6-1/2"

4-1/5"

4"

3"

22" 7"

5"

4-3/4"

3-3/4"

23" 7-3/4"

5-1/2" 5-1/4" 4-1/4"

24" 8-1/4"

6-1/2" 5-3/4" 4-3/4"

25" 9"

6-3/4"

6-1/2"

5-1/2"

26" 9-1/2"

7-1/2"

7"

6"

27" 10"

8"

7-1/2"

6-1/2"

28" 10-1/2"

8-1/2"

8"

7"

29" 11-1//4"

9"

8-3/4"

7-3/4"

30" 11-3/4"

9-3/4" 9-1/4" 8-1/4"

31" 12-3/4"

10-1/4" 9-3/4" 8-3/4"

Figure 4

NOZZLE STAND-OFF DISTANCE for 32" TO 60" ID pipe

LONG VENTURI NOZZLE

PIPE INSIDE

SHORT

1/4"

5/16"

3/8"

DIAMETER VENTURI

NOZZLE Orifice Orifice Orifice

32" to 36" W/O Extensions

13" to 15-1/4"

10-3/4" to 13"

10-1/2" to 12-3/4"

9-1/2" to 11-3/4"

32" to 36" W/6" Extensions

7" to 9-1/2"

4-3/4" to 7"

4-1/2" to 6-3/4

N/A

37" to 47" W/6" Extensions

9-3/4" to 15-1/2"

7-3/4" to 13-1/5"

7-1/4" to 13"

6-1/4" to 12"

48" to 60" W/12" Extensions

10" to 17"

8" to 15"

7-3/4" to 14-3/4"

6-3/4" to 13-3/4"

53" to 60" W/18" Extensions

7" to 11"

5" to 9"

4-1/2" to 8-3/4

3-1/2" to 7-3/4"

Figure 5

FORMULA TO CALCULATE NOZZLE STAND-OFF

FOR 32" to 60" PIPE

NOZZLE TYPE

BASE DIMENSION

@ 32” DIA. PIPE

Short Venturi

13 Inches

1/4" Orifice Long Venturi

11 Inches

5/16" Orifice Long Venturi

10-1/2 Inches

3/8" Orifice Long Venturi

9-1/2

Inches

To obtain stand-off distance for pipe larger than 32", add

0.58" for every inch over 32 and subtract length of nozzle

extension.

For example, to calculate the stand-off distance of a 48

inch diameter pipe when using a No. 5 long venturi nozzle

Subtract 32" from 48" = 16"

Multiply 0.58" x 16 = 9.28 (9-1/4")

Add 9-1/4" to No. 5 base dim. (9.1/4 + 10-1/2" = 19-3/4")

The stand-off distance is approximately 19-3/4".

When using a nozzle extension subtract the length of the

extension. In the case of the example:

Subtract 6" for a 6" extension (19-3/4" - 6" = 13-3/4"

stand-off).

Subtract 12" for a 12" extension (19-3/4" - 12" = 7-3/4"

stand-off).

Figure 6