PIPE-PRO XL™ INTERNAL-PIPE BLAST TOOL

Page 7

© 2017 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 27804 Rev A

Figure

10

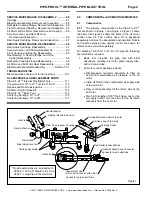

5.3 Air

Motor

Connections

5.3.1

Assemble and attach the inlet and outlet tube

connectors as shown in Figures 1 and 2. The inlet tube

connector with filter must be connected to the green inlet

tube. To attach the connectors to the tubing, simply insert

the tubing through the collar and push until it bottoms out

in the fitting. Tug on the tube to make sure it is secured.

To release the connectors, refer to Figure 11. An arrow on

the inlet tube shows the direction of air flow; the green

tube, with the arrow pointing toward the tool is the inlet,

the red tube is the outlet.

NOTE: If the arrow or tubing

are removed or damaged, use a flashlight to look into

the carriage collar; the green inlet tube goes to the

"R" port on the air motor, the red outlet tube goes to

the "EXH" port on the motor.

Figure

11

5.3.2

Refer to Figure 12 and set up an air supply to

the 3/8" x 50' air hose provided with the tool.

NOTICE

To reduce the risk of abrasive ingress into the

air motor, cover air motor fittings and hose ends

when disconnecting air hoses from the tool. Any

dust or abrasive from the air supply, which

enters the air motor, will cause the air motor to

fail. Motor failure from ingress of dust, abrasive,

or any foreign matter voids the warranty.

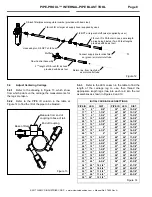

5.3.3

The air supply line to the filter/regulator inlet and

the smallest inside diameter of any connections must be

at least 3/8" ID. Increase the inside diameter to 1/2"

when using more than one section of supply hose;

multiple connections of 3/8" hose could restrict air

volume needed to operate the air motor.

NOTICE

A combination filter/pressure regulator is

provided and must be installed in the air motor

air supply line. The filter removes particles that

could damage the motor. The pressure regulator

reduces pressure to below 100 psi. Maximum

operating pressure for the air motor is 100 psi.

5.3.4

Attach one 3/8" air hose from the air supply

(filter/regulator) to the air motor inlet-tube connector, as

shown in Figure 12. The inlet tube is identifiable by its

green color and inline filter. The hose must be long

enough to reach between both ends of the pipe being

blasted; attach additional lengths of hose as needed.

5.3.5

Attach the flow-control assembly to one end of

the second 3/8" hose and attach the other end to the

tube connector on the red outlet tube from the air motor;

this hose must also be long enough to reach between

both ends of the pipe being blasted.

5.3.6

The flow-control valve should be placed at

approximately the same location as the blasting control

handle. Air flow through the motor begins when the flow-

control valve is opened, the more the flow-valve is

opened, the faster the head rotates. The head stops

rotating when the flow-control valve or shutoff valve is

closed. The flow-control valve is opened or closed, as

required to rotate the blast head at 40-60 rpm.

Push collar in to release tubing

Pull tubing straight out

Retaining Collar

Collar Couplings

8 mm Cap Screw

Rail Extension

Rail

8 mm Lock Nut

Make sure all legs are

inserted from the same side