PIPE-PRO XL™ INTERNAL-PIPE BLAST TOOL

Page 8

© 2017 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 27804 Rev A

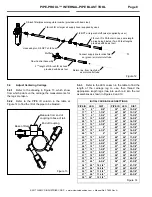

Figure 12

5.4

Adjust Centering Carriage

5.4.1

Refer to the drawing in Figure 13, which show

from which points on the carriage the measurements for

the legs are taken.

5.4.2

Refer to the PIPE ID column in the table at

Figure 14 to find the ID of the pipe to be blasted.

Figure

13

5.4.3

Refer to the LEG column in the table to find the

length of the carriage leg to use, then thread the

appropriate length legs (two into each rail) into the rail

assemblies as shown in Figures 9 and 10.

INITIAL CARRIAGE LEG SETTINGS

PIPE ID

LEG

DIST.

PIPE ID

LEG

DIST.

16" 6" 5/8" 39" 26" 12-3/4"

17" 6"

1-1/4" 40" 26" 13-1/4"

18" 6"

1-3/4" 41" 26" 13-3/4"

19"

12"

2-3/8" 42" 26" 14-3/8"

20"

12"

2-7/8" 43" 26" 14-7/8"

21"

12"

3-3/8" 44" 26" 15-3/8"

22"

12" 4" 45" 26" 15-7/8"

23"

12"

4-1/2" 46" 26" 16-3/8"

24"

12" 5" 47" 26" 16-7/8"

25"

12"

5-1/2" 48" 26" 17-3/8"

26"

12"

6-1/8" 49" 26" 17-7/8"

27"

12"

6-5/8" 50" 26" 18-3/8"

28"

12"

7-1/8" 51" 26" 18-7/8"

29"

12"

7-5/8" 52" 26" 19-3/8"

30"

12"

8-1/8" 53" 26" 19-7/8"

31"

12"

8-5/8" 54" 26" 20-3/8"

32"

26"

9-1/4" 55" 26" 20-7/8"

33"

26"

9-3/4" 56" 26" 21-3/8"

34"

26" 10-1/4" 57" 26" 21-7/8"

35"

26" 10-3/4" 58" 26" 22-3/8"

36"

26" 11-1/4" 59" 26" 22-7/8"

37"

26" 11-3/4" 60" 26" 23-3/8"

38"

26" 12-1/4"

Figure 14

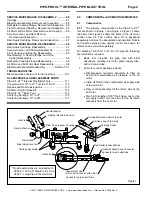

3/8-NPT or larger shutoff valve (supplied by user)

3/8-inch filter/pressure regulator combo (provided with basic tool)

3/8-inch ID or larger air supply hose (supplied by user)

3/8-inch ID x 50-foot air hose, same length

a pipe being blasted (Two 50 feet lengths

provided with basic tool)

Return line, from (red tube)

air motor outlet tube

Muffler

Hose adaptor, 3/8 NPT x 3/8 hose

Flow Control Assembly

2

nd

length of 3/8-inch ID air hose

provided with basic tool

Connect supply line to inline filter

on (green) air motor inlet tube

Base of Rail

Measure from end of

coupling to base of rail.

End of Coupling