Page 4 of 15

2 Product description

2.1 Conventional utilization and restrictions

Parts to be blasted

-

Inside of pipes

-

Inside of cylindrical parts

Operating conditions

-

indoor or outdoor

-

acceptable temperature: -5° ... 40°C

-

acceptable humidity: 0 ... < 100% (no rain!)

Compressed Air

-

pressure: 6 to 8bar

-

pressure air category 4, DIN ISO 8573

-

air volume: see table 1

-

air service unit for air motor:

max. part size: 15μm

max. part density: 8mg/m³

dry air: water content max. 6g/m³

oil free!

Acceptable

medias/ abrasives

-

mineral and metallic blast media

-

acceptable size see table 1

-

dry and pourable

-

use of Aluminium Oxide and Silicium Carbid causes high wear

Suggestion for parameters

see table 1

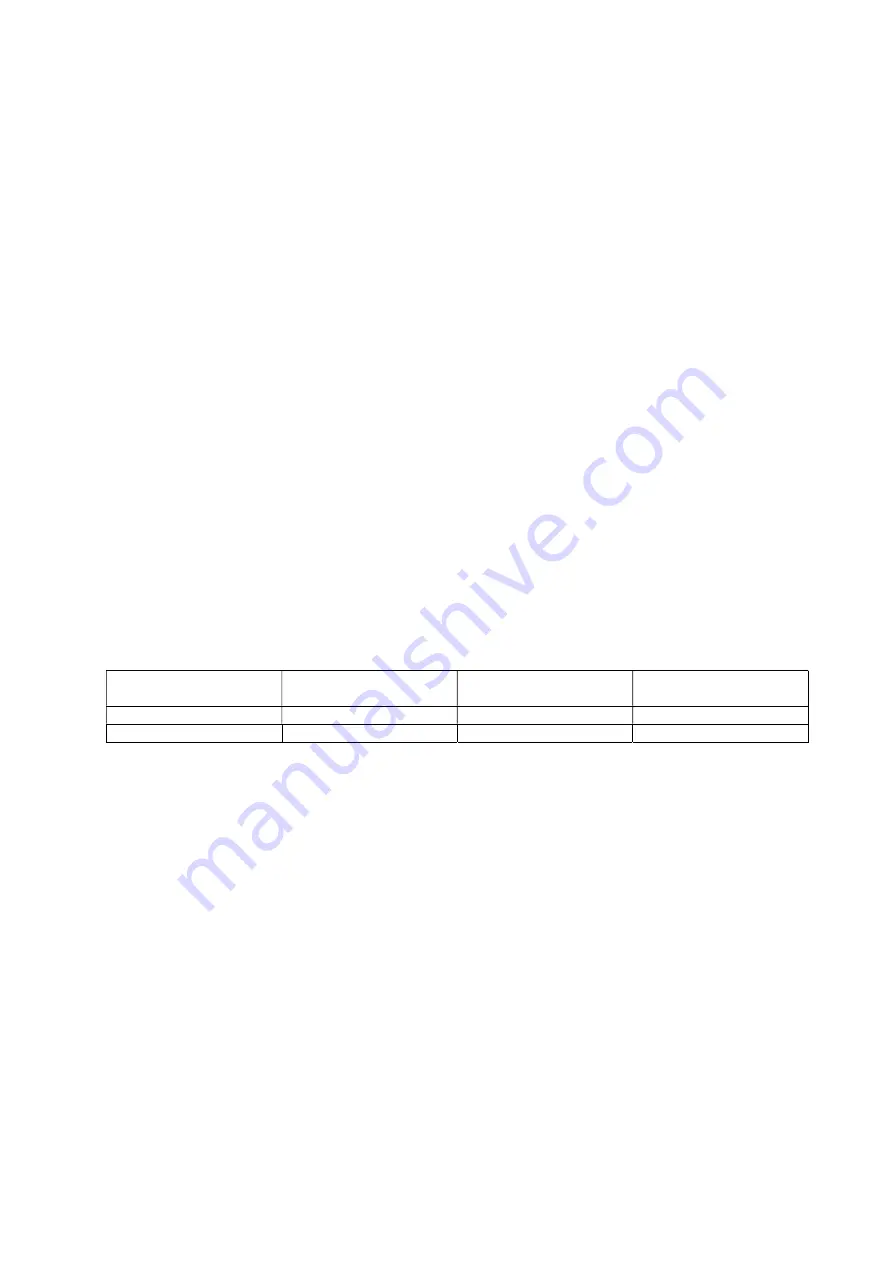

Table 1:

for inner diameter

(mm)

nozzle-Ø

Size of blast media (µ)

Min. air volume

(m³/min)

400 - 700

8,0

400-800

10,0 (353 CFM)

700 - 1500

9,5

(400) 800-1200

15,0 (530 CFM)

2.2 No conventional utilisation – Warnings for misuse

Utilization is interdicted:

-

in explosion hazard zones

-

for blasting parts, where hazardous materials were released

o

by explosion hazards

o

which causes damages caused to somebody's health during a defective dust collector

2.3 Operating mode of complete system

-

place Spin XL at the end of the pipe

-

switch on system

-

air motor turns blast head

-

air-blast media mixture escapes radial

-

pull back equipment manually: inner surface of pipe gets blasted/ cleaned

-

blastmedia-dust mixture gets exhausted at end of pipe (option)

2.4 Description

2.4.1 Complete system

To get the CE-conformance Clemco recommends the following components/ activities:

Summary of Contents for Spin - XL

Page 12: ...Page 12 of 15 10 Appendixes 10 1 Manual for air motor type MRD stall proof oil free...

Page 13: ...Page 13 of 15...

Page 14: ...Page 14 of 15...

Page 15: ...Page 15 of 15...