MEDIA RECLAIMER / SEPARATOR

Page 9

© 2005 CLEMCO INDUSTRIES CORP.

•

www.clemcoindustries.com

•

Manual No. 23438

•

Rev. E

static pressure has been adjusted, adjust the cylinder as

follows.

5.2.1

The adjusting lever for the vortex cylinder is

mounted on the outlet pipe on top of the reclaimer or the

spacer between the reclaimer body and exhauster

housing depending upon which system is provided.

5.2.2

Adjustments are made by loosing the handle's

locking knob and moving the handle to achieve the

correct setting. When the correct setting is established,

tighten the locking knob to prevent movement.

5.2.3

Start with the lever slightly to the right (about

one o’clock) of the vertical position.

5.2.4 Dusty

Media:

To increase media consumption,

raise the cylinder by moving the lever left toward

"COARSE", in 1/4" increments at the indicator plate. Do

not adjust again until the media has gone through

several cycles, to be certain that further adjustment is

required.

5.2.5 Media Carryover:

To decrease media

consumption (excessive usable media is being carried to

the dust collector), lower the vortex cylinder by moving

the lever right toward "FINE", in 1/4" increments at the

indicator plate. Note: If the cylinder is lowered too far,

the reclaimer will again begin to allow usable media to

be carried over, and cause abnormally high static

pressure.

5.2.6

When using very fine media (200 mesh and finer

or plastic media), the inlet baffle of the reclaimer may

also need to be removed. Consult the factory before

proceeding with this option.

5.3

Internal Vortex Cylinder

Note: Before adjusting the vortex cylinder, adjust

the damper per Section 5.1. After the static pressure

has been adjusted, adjust the cylinder as follows.

5.3.1

Remove the flex hose from the outlet pipe or

remove the exhauster assembly, depending on the

reclaimer style.

5.3.2

The internal cylinder is visible by looking into the

reclaimer from the top. The cylinder is held in position

with three bolts.

5.3.3

Adjustments are made by loosening the bolts,

and moving the cylinder up or down to achieve the

correct setting. When the correct setting is established,

tighten the bolts to prevent movement.

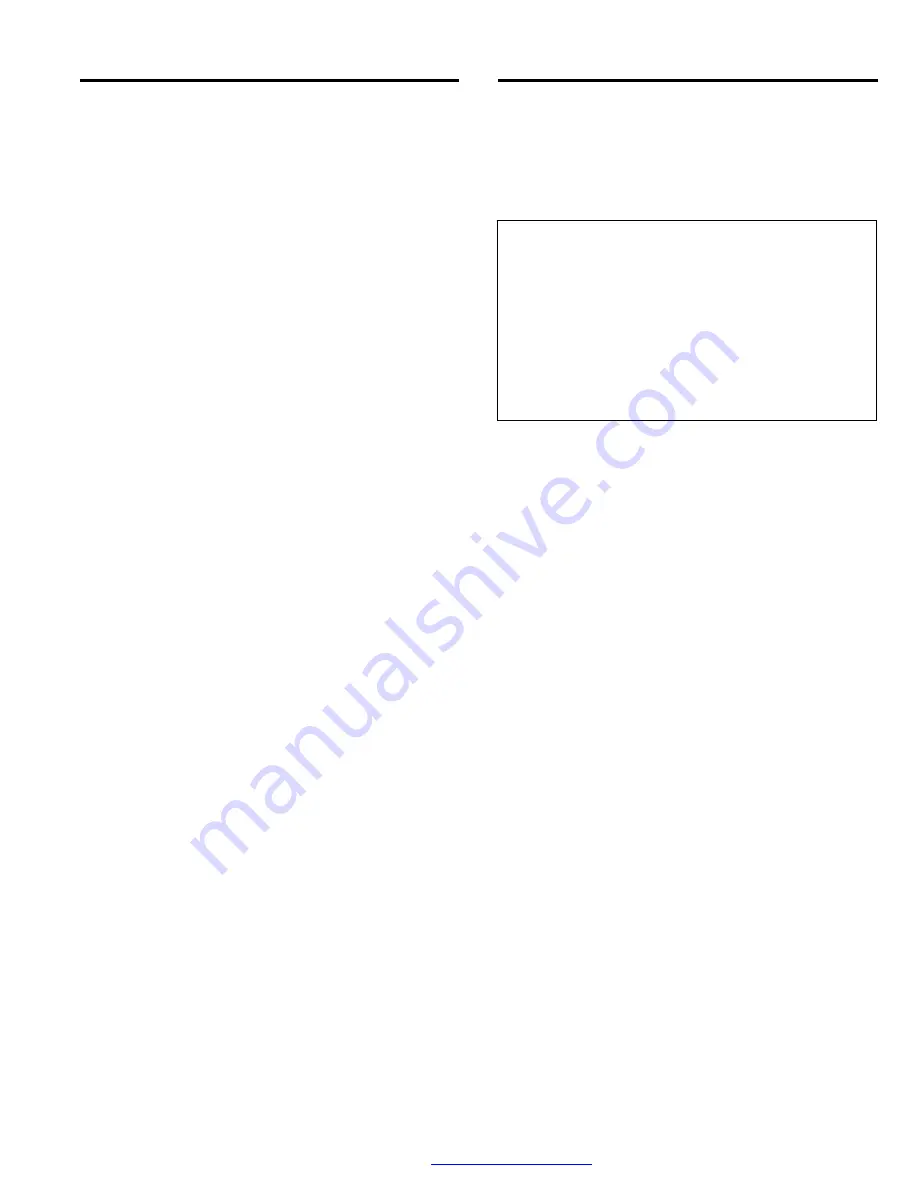

5.3.4

Start with overall length of the internal tube and

cylinder, when measured from the top of the reclaimer to

the bottom of the inner cylinder equaling the distance

shown in Figure 7. If the reclaimer is rubber lined, add

1/4

″

to the starting point depth.

Reclaimer Size

Starting Point Depth

900

cfm .........................................15 1/2 Inches

1200

cfm .......................................18 1/2 Inches

1800

cfm .......................................20 1/2 Inches

2500

cfm .......................................22 1/2 Inches

3200

cfm .......................................24 1/2 Inches

3600

cfm .......................................25 1/2 Inches

Figure

7

5.3.5 Dusty

Media:

To increase media consumption,

raise the cylinder in 1/4" increments. Do not adjust again

until the media has gone through several cycles, to be

certain that further adjustment is required.

5.3.6 Media Carryover:

To decrease media

consumption, lower the vortex cylinder in 1/4"

increments. NOTE: If the cylinder is lowered too far,

usable media will carryover, and cause abnormally high

static pressure.

5.3.7

When using very fine media (200 mesh and finer

or plastic media), the inlet baffle of the reclaimer may

need to be removed. Consult the factory before

proceeding with this option.

5.4

Metering Valve Adjustment, Figure 8

5.4.1

While blasting, check the media stream through

the blast nozzle, or through each, clear, metering valve

tube. With the correct media/air mixture, media will flow

smoothly through the tube and nozzle.

5.4.2

If media does not flow smoothly, loosen the

locking nut, and adjust the metering screw until the upper

holes in the metering stem are closed-off, and the lower

holes are fully open. See Figure 8. This adjustment is a

starting point.

5.4.3

If pulsation occurs in the media hose, either media

is damp and caked, or not enough air is entering the media

stream. While blasting, loosen the locking nut and slowly

turn the adjusting screw out (counterclockwise when

viewed from the top) until the media flows smoothly.

Tighten the locking nut finger-tight to maintain the setting.