MEDIA RECLAIMER / SEPARATOR

Page 4

© 2005 CLEMCO INDUSTRIES CORP.

•

www.clemcoindustries.com

•

Manual No. 23438

•

Rev. E

without the inlet baffle. The adjustable vortex cylinder

should be installed when using 200-mesh and finer

media.

1.8.9 Lightweight

Media:

When using plastic media,

and most agricultural media, the inlet baffle of the

reclaimer may need to be removed. Consult the factory

before proceeding with this option. Reclaimers can be

ordered from the factory without the inlet baffle. The

adjustable vortex cylinder should be installed when

using lightweight media.

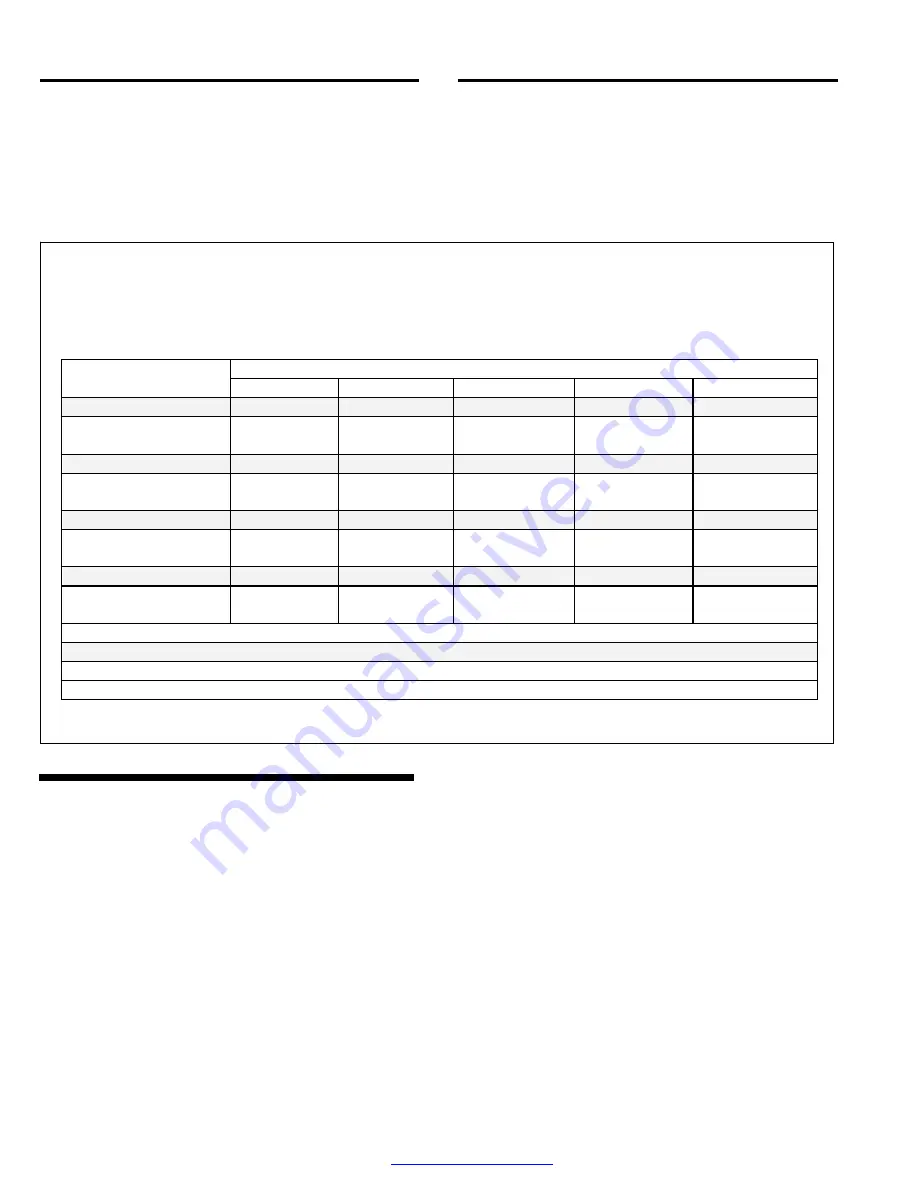

Media sizes shown below are guidelines only, and based on average conditions, such as contamination of parts

being cleaned, humidity, media friability, reclaimer loading rate, etc. Any air restrictions external of the reclaimer

will affect usable media size. Media finer than those shown may decrease visibility in the blast enclosure, and at

some point carryover to the dust collector. Media coarser than those shown may be too large for the reclaimer to

recover from the enclosure.

MEDIA TYPE

RECLAIMER SIZE

STEEL GRIT

STEEL SHOT

PLASTIC

GLASS BEAD

ALUM. OXIDE

900 cfm with 5" inlet

40 & finer

170 & finer

Do not use

Do not use

16 to 36

900 cfm with 6" inlet

Do not use

Do not use

*12 to 40

#6 to #12

*

#13

46 to 200

* 220 to 320

1200 cfm with 6” inlet

40 & finer

170 & finer

Do not use

Do not use

16 to 60

1200 cfm with 7” inlet

Do not use

Do not use

*All sizes

#6 to #12

*

#13

46 to 200

* 220 to 320

1800 cfm with 7” inlet

25 & finer

280 & finer

Do not use

Do not use

16 to 60

1800 cfm with 8” inlet

Do not use

Do not use

*All sizes

#6 to #12

*

#13

46 to 200

* 220 to 320

2500 cfm with 8” inlet

25 & finer

280 & finer

Do not use

Do not use

16 to 60

2500 cfm with 10” inlet

Do not use

Do not use

*All sizes

#6 to #12

*

#13

46 to 200

* 220 to 320

Shaded lines represent reclaimers with reduced sized inlet

Non shaded lines represent standard reclaimers

* To utilize these size media baffle is removed from the reclaimer

Figure 2

2.0 INSTALLATION

Installation Notes:

The externally adjustable vortex

cylinder and exhauster can be rotated, to align the

reclaimer inlet, vortex adjustment handle, and

exhauster outlet, to the most efficient positions.

Determine the best location for all components, and

position all segments before final assembly.

2.1 Placement

2.1.1

General arrangement drawings are provided on

job orders (equipment built around user specifications).

Place the reclaimer as close as possible to the

orientation or as shown on the floor plan of those

drawings.

2.1.2

Position the reclaimer to provide full access to

load and unload media, and to service the vortex

cylinder and metering valves. For optimum efficiency

and the least amount of equipment wear, the reclaimer

should be located directly behind, and as close as

possible the cabinet or room enclosure.

2.1.3

Rotate the reclaimer, to enable connection of

the inlet flex hose with as few bends as possible.

2.1.4

Rotate the externally adjustable vortex cylinder

and exhauster, to align the vortex adjustment handle,

and exhauster outlet, to the most efficient positions.