DCM-161 MINI TUMBLE BLAST CABINET

Page 4

3.4.5

Start the blast cycle by setting the timer for the

blast duration. Blasting begins as soon as the timer is

set.

3.3

Loading and Unloading Parts

3.3.1

Parts must be free of oil, water, grease, or other

contaminants that will cause media to clump or

contaminate parts.

3.3.2

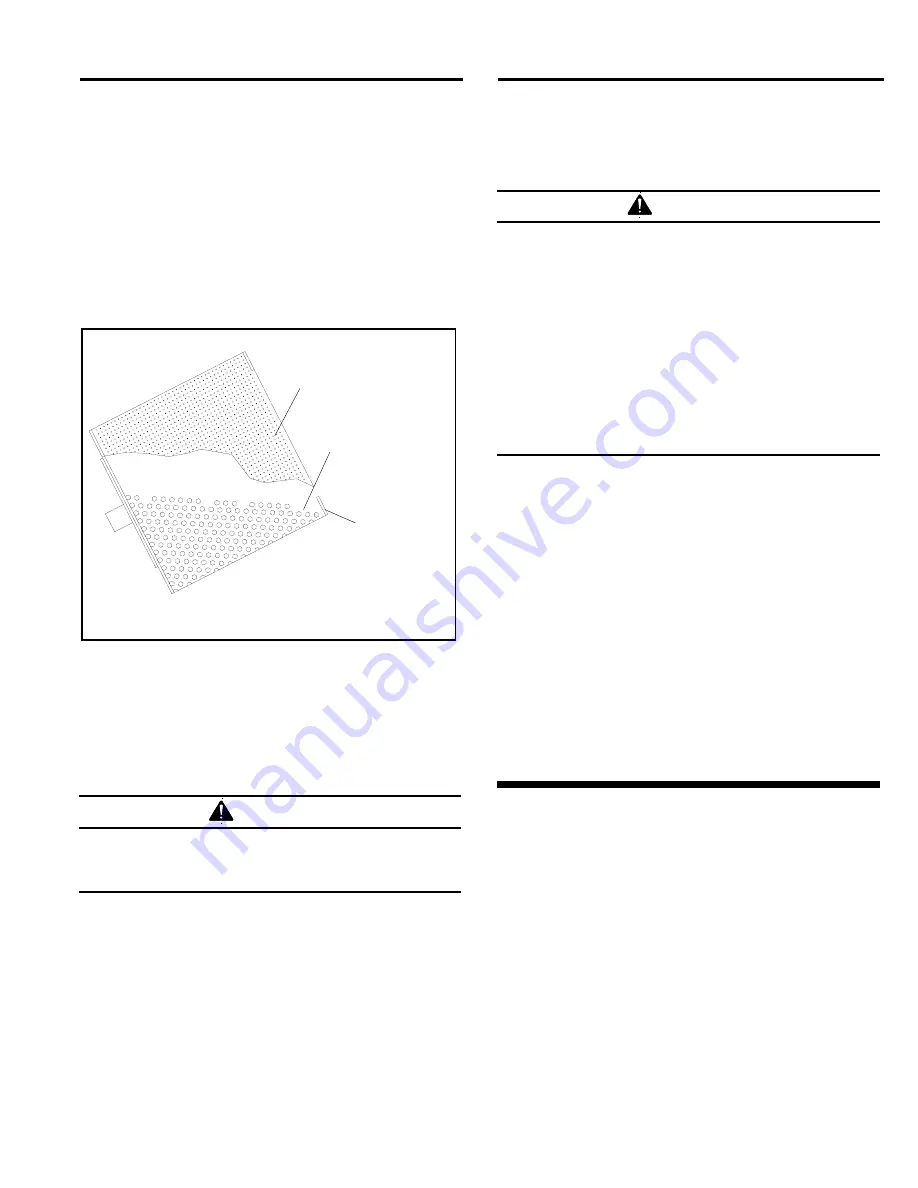

Load parts directly into the tumble barrel. Do not

overload the barrel; maximum load should not exceed 25

lb., or the lower edge of the retainer as shown in Figure

2.

Figure

2

3.3.3

Close the cabinet door. Be certain door is

latched securely, or door interlock system will prevent

blasting.

3.4 Blasting

Operation

•

Keep door closed during blasting.

•

Stop blasting immediately if dust leaks are

detected.

3.4.1

Slowly open the air valve on the air supply hose

to the cabinet. Check for air leaks on the initial start up,

and periodically thereafter.

3.4.2

Adjust the pressure regulator (filter/regulator)

located on the side of the cabinet, to the required blast

pressure per Section 4.1.

3.4.3

Load media and parts.

3.4.4

Close door and latch securely.

Shut down the cabinet immediately if dust

discharges from the cabinet or filter bag. Make

sure that the bag is clamped securely over the

exhauster outlet, and that it is not worn or

damaged. Prolonged breathing of any dust

could result in serious lung disease. Short term

ingestion of toxic dust such as lead, poses an

immediate danger to health. Toxicity and health

risk vary with type of media and dust generated

by blasting. Identify all material being removed

by blasting, and obtain a material safety data

sheet for the blast media.

WARNING

Do not load parts

above the bottom

rim of the retainer.

Tumble Barrel

Retainer

3.4.6

Check media flow per Section 4.3.

3.5 Stop

Blasting

3.5.1

Blasting, and barrel rotation, and the exhauster

stop when the timer cycle is complete.

3.5.2

Open the door only enough to disengage the

door interlock, and turn the timer on. Let it run for several

seconds to clear airborne dust, then turn the switch off.

3.5.3

Remove parts and check blast coverage.

3.5.4

When finished, shut off the air supply valve,

drain the air filter.

CAUTION

4.0 ADJUSTMENTS

4.1 Blasting

Pressure

4.1.1

The filter/regulator, enables the user to adjust

blasting pressure to suit the application. The maximum

recommended pressure is 60 psi. Lower pressures may

be used for delicate work. Higher pressure may cause

dust or media to escape from the cabinet.

4.1.2

To adjust, unlock the knob, and turn it clockwise

to increase pressure or counter-clockwise to decrease

pressure. Pressure will usually drop from closed-line

pressure when blasting starts. Once operating pressure

is set, lock the knob to maintain the setting.