S-2R + Frontanbau 11.2018 en

15

6.1 Road and transport journey

In order to avoid traffic obstructions, road haulage all attachments and work equipment, as

well as of the tractor, should be cleared of any major debris that might be released while

driving on the road.

When driving on public roads, the Road Traffic Licensing Regulations must be observed.

6.2 Operation and adjustment of the machine

The hydraulic height adjustment may only be operated from the driver's seat.

Lowering the column lifter must be slow to avoid damaging the unit and the tools or

attachments.

The adjustment of the working depth of implements can be done during work by actuating

the cylinder of the lifter.

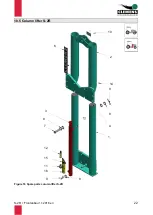

6.3 Removal from the tractor

When uncoupling the hydraulic lines, they should be depressurized.

In case of loose ground pay attention to the stability of the parked equipment. In order to

prevent overturning, the support wheels should be equipped with wheel chocks and all

supports should be unfolded / extended and locked.

Now you can carefully loosen the screwed clamps between the column lifter and the

mounting brackets. While doing this, the equipment is to be secured against falling.

Please also observe the instructions for securing the hoist in chapter 5.1 Attachment of the

column lifter to the tractor.

7 Maintenance and replacement of wearing parts

Attention:

Always carry out maintenance work with the drive and motor switched off!

Remove ignition key!

Secure tractor and machine against unwanted movements (e.g. rolling away,

lowering, etc.)!

Observe the relevant accident prevention regulations and all other information

given in the operating instructions!

Please only use original spare parts.