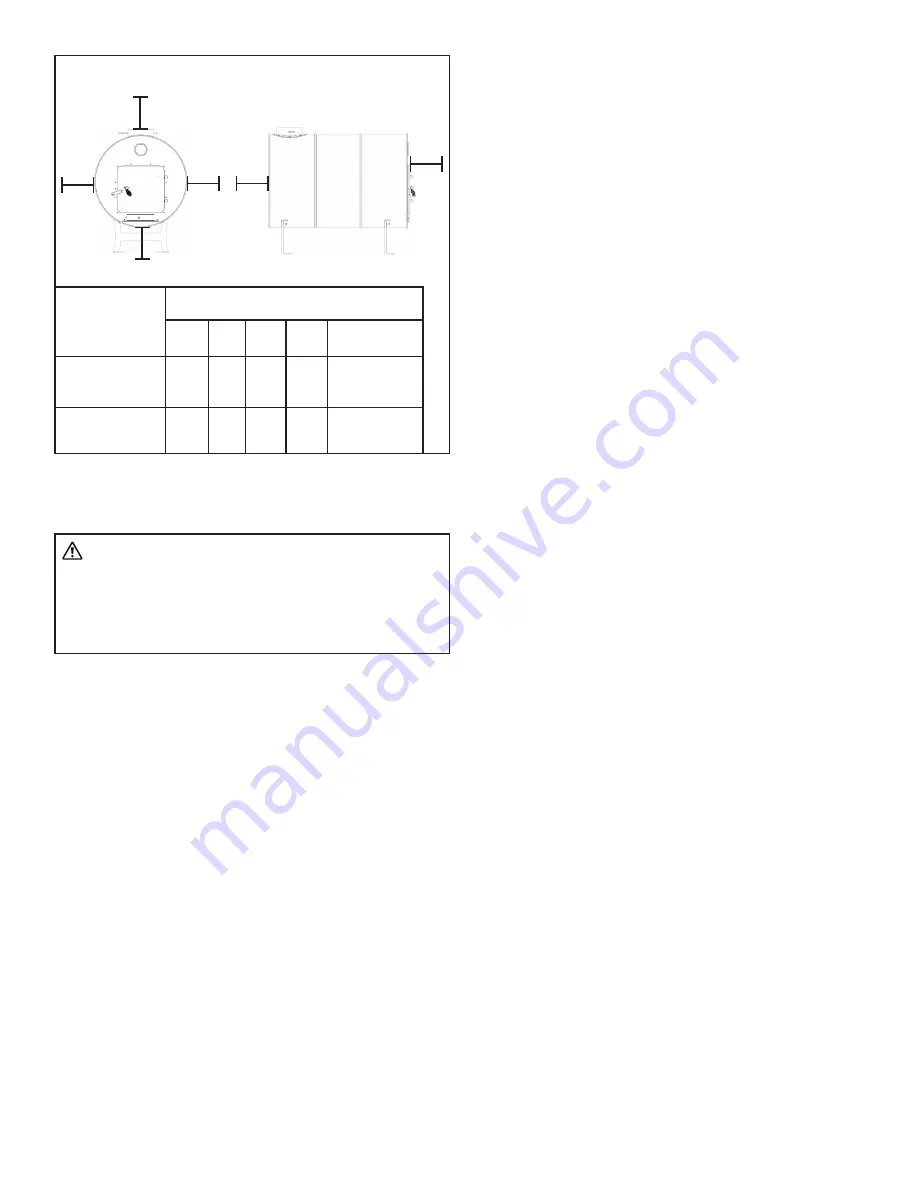

Clearances to Combustibles

Side

Materials

Clearance to Combustibles

Front Top Rear Side

Floor

wood / plaster

board

72”

72” 36” 36”

Not for use on

combustible

flooring

Concrete /

Masonry

72”

72” 36”

36”

Leg Height

(8 inches)

Floor

Top

Side

Front

Rear

ASSEMBLY INSTRUCTIONS

WARNING: Make sure barrels are

thoroughly clean before applying barrel

stove kit. NEVER USE AN ACETYLENE

TORCH due to explosive gases that may be

trapped inside your barrel.

1. Open the barrel plug and displace vapors with water

to make barrel safe for power tools. (Figure 1)

2. Ensure the barrel is empty and dry before beginning

the installation of barrel stove kit.

3. Stand barrel upright, with a barrel plug facing up. If

there are extra holes in the barrel beside this plug,

permanently seal them shut.

4. Using a scribe or marking pencil, trace the inner

perimeter of the door and of the air inlet vent.

5. Cut along these markings with either a hacksaw or

sabre saw.

6.

Apply high temperature sealant around the cut

openings

, then press the door frame against the

sealant and over the holes. Secure the door frame

to the barrel using bolts provided with the kit.

(Figure 2)

7. Position the legs underneath the barrel, near the

front and rear of the barrel and balanced around

the center of the barrel so that the barrel is level

and stable. With the door frame attached, access

the inside of the barrel to secure the legs. (Figure 3)

8. Protect and elongate the useful life of your stove by

lining the bottom with fire bricks or loose gravel.

9. Attach the flue collar at the rear and top of barrel

by the same process as the door:

• Mark the inner perimeter.

• Use either a hacksaw or a sabre saw to cut along

the marking.

• Use high temperature sealant along the cut.

• Press the flue collar into the high temperature

sealant against the opening.

• Secure the flue collar with the 6 included bolts.

(Figure 4).

For single barrel stoves, ki

t F500300

10. Attach the flue damper to the flue collar. (Figure 8)

For double barrel stoves, kit F500305

11. Position the connecting legs on top of the barrel,

near the front and rear of the barrel and balanced

around the center of the barrel so that the

second barrel may be supported securely. When

positioning the back legs be sure to not obstruct

the flue collar. With the door frame attached,

access the inside of the barrel to secure the legs.

(Figure 5)

10. Cut 6” diameter flue pipe long enough to connect

the two barrels

. Insert into flue collar.

11. With help, hoist the second barrel on top of the

first and adjust position until the barrels are aligned

and balanced.

12. Mark the perimeter of the 6” flue pipe on the

underside of the top barrel.

13. Remove the top barrel. Using either a hacksaw or a

sabre saw cut along the markings. Trace then cut a

flue collar inner perimeter on the opposite end and

side of the barrel. (Figure 6) For both openings on

this barrel, fasten flue collars to the barrel with the

same procedure as step 9.

14. With help, hoist the second barrel back on top of

the first barrel and support legs. Align the barrel

so that the flue pipe fits snug into the flue collar of

bottom and top barrel. Fasten barrel to legs. Reach

through top flue collar to insert, arrange, and

tighten nuts (Figure 7). Fasten the underside flue

collar to the stove pipe.

15. Install flue damper to top barrel. (Figure 8)