4

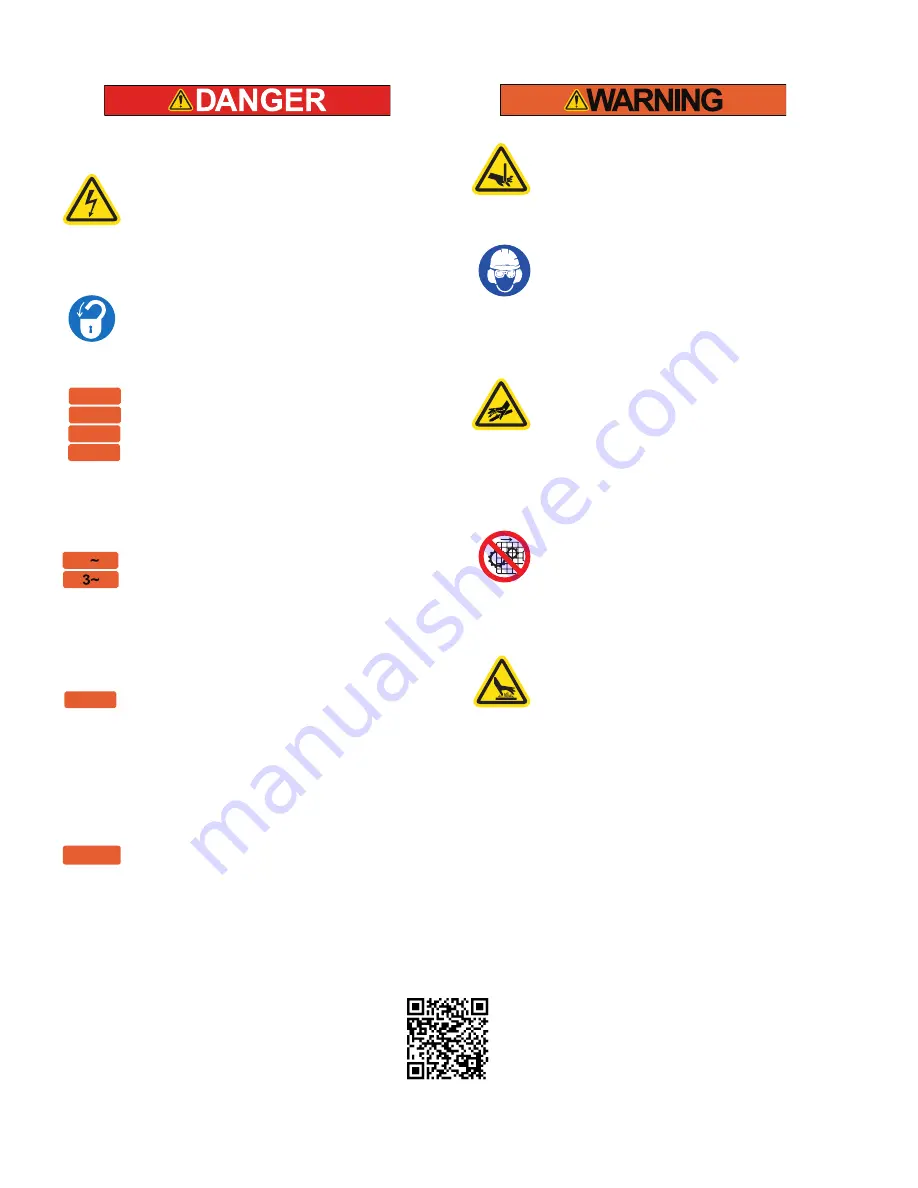

Danger Panel

Warning Panel

Electrical Hazard

High voltages present inside the enclosure of

this product. ONLY qualified, authorized, mainte-

nance, service or Certified Electricians should gain

access to electrical panel. Do not operate this

equipment from any power source that does not

match the voltage rating stamped on the equip-

ment. Refer to the Manufacturer’s Identification

Label for operational requirements.

Lockout Power

Danger circuits are live. Lockout/Tagout the

upstream power source. Lockout/Tagout machin-

ery according to Employer procedures.

Voltage (Varies by consumer requirement)

Indication of operating power requirements. This

product should be operated only from the type of

source indicated on the manufacturer’s identifica-

tion label. Installation should be in compliance with

applicable sections of the National Electric Code.

Consult your local building code before installing.

Phase (Varies by consumer requirement)

Indication of electrical phase requirements. This

product should be operated only from the type of

source indicated on the manufacturer’s identifica-

tion label. Installation should be in compliance with

applicable sections of the National Electric Code.

Consult your local building code before installing.

Horsepower

Indication of horsepower requirements. This prod-

uct should be operated only from the type of

source indicated on the manufacturer’s identifica-

tion label. Installation should be in compliance with

applicable sections of the National Electric Code.

Consult your local building code before installing.

Hertz

Indication of electrical cycles per second. This

product should be operated only from the type of

source indicated on the manufacturer’s identifica-

tion label. Installation should be in compliance with

applicable sections of the National Electric Code.

Consult your local building code before installing.

Shear/Crush Hazard

Moving parts can cut and crush. Keep hands

clear while operating. Lockout power before

servicing. Immediately replace guards after

adjustment, repair or service.

Wear Personal Protective Equipment

To avoid physical hazard, always wear personal

protective equipment. Wear protective eye-

wear, clothing, gloves, footwear, head-gear and

hearing protection while operating or servicing

this machinery.

Fluid Injection Hazard

Hydraulic hoses and cylinders are under

pressure. Pressurized fluid can pierce skin and

cause severe injury. To avoid physical hazard,

always wear personal protective equipment.

Keep hands clear while operating. Lockout

power before servicing. Immediately replace

guards after adjustment, repair or service.

Do Not Operate With Guard Removed

Physical barriers and guards have been

designed and installed to protect the opera-

tor from moving parts that can pinch, cut and

crush. Keep hands clear while operating.

Lockout power before servicing. Immediately

replace guards after adjustment, repair or ser-

vice to moving parts.

Heat Hazard

To avoid physical burn hazard, always

wear personal protective equipment. Wear

protective clothing and gloves while working

adjacent to or on the affected surface.

Visit our website to view our Ironworkers in action.

https://www.clevelandsteeltool.com/catalog-and-literature/videos

208 V

230 V

460 V

575 V

1

5 hp

60 Hz

Summary of Contents for 55 Ton

Page 2: ......

Page 41: ...37 55 Ton Exploded View ...

Page 42: ...38 55 Ton Parts List ...

Page 44: ...40 www clevelandsteeltool com 474 E 105th St Cleveland OH 44108 800 446 4402 ...