5

Electronics

Electronic equipment must be recycled as required

by local environmental law. Do not dispose of by

adding to the municipal waste stream.

Metal

Metal components must be recycled as required

by local environmental law. Do not dispose of by

adding to the municipal waste stream.

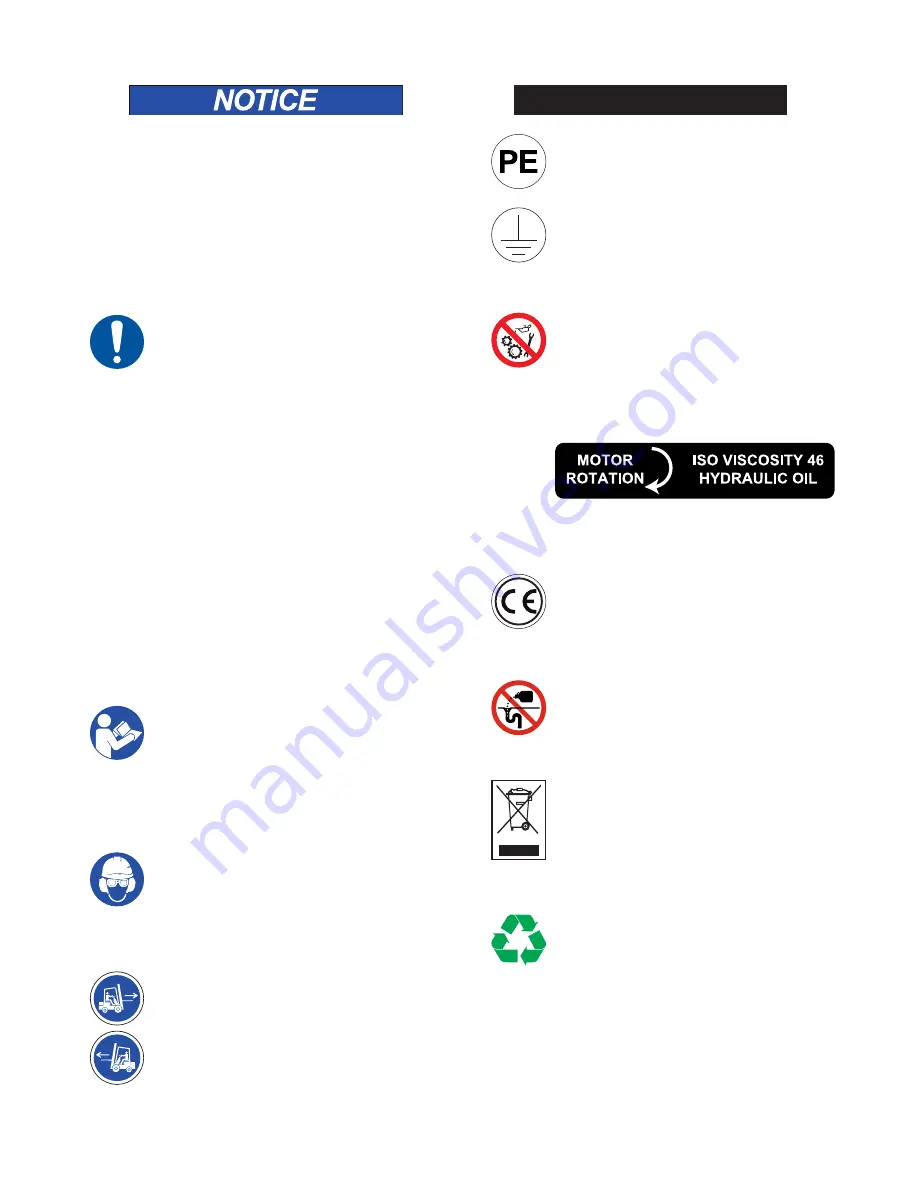

Notice Panel

Ironworker Operation

This manual outlines the basic functions

associated with typical Ironworker operations and

is neither intended to create a comprehensive

list, nor describe every operation possible with an

Ironworker tool. Ironworker machines are designed

to punch, shear and notch mild steel (A36) plate,

barstock and angle. A wide range of accessories

are available to fabricate rod, square stock, sheet

metal and pipe. Cleveland Steel Tool Ironworkers

operate by applying hydraulic force to a moving

center. The center moves within a frame in a

simple, vertical path and exerts force through

Shear Blades, Punches and Dies, Notchers,

Press Brake dies or Rod/Multi-Shear tooling upon

A36 mild steel. Cleveland Steel Tool Ironworkers

are designed for single operator use only. DO

NOT USE THIS EQUIPMENT FOR ANY PURPOSE

NOT DESCRIBED IN THE MANUAL. Ironworker

machines are dangerous and require extreme care

and caution in the safe installation, operation and

maintenance of the machinery. Cleveland Steel Tool

strongly suggests reading and understanding the

manual associated with the machinery as well as

obtaining certified, technical, industrial machinery

operations and maintenance training to reduce

the risk of injury. Regardless of the contents of the

machinery manual, Cleveland Steel Tool will not be

held liable for accidents caused by lack of training.

Wear Personal Protective Equipment

To avoid physical hazard, always wear personal

protective equipment. Wear protective eyewear,

clothing, gloves, footwear, head-gear and hearing

protection while operating or servicing this

machinery.

Forklift Location

This machine is equipped with rated forklift move-

ment points. Do not attempt to lift the machinery

by any other means. Inappropriate movement of

the machinery may result in serious operator injury,

machine damage and will void machine warranty.

Consult the installation manual for equipment

weight ratings. Provide rated forklift and certified

forklift operator to move machinery to appropriate

location.

Safety, Installation, Operations and

Maintenance

This manual contains critical instructions regarding

proper procedures for your machinery. Understand

the contents thoroughly. Failure to follow proper

procedures may result in serious operator injury,

machine damage and will void your machine

warranty. Keep the manual close to the machine

for easy reference.

Safety Ground

Safety earth ground location.

Do Not Use Non-Approved Lubricants

This machine requires lubrication of moving

mechanical parts (grease) and the maintenance of

hydraulic fluids. Refer to maintenance sections for

specific lubrication requirements and application

or maintenance schedules.

PE

‘Protective earth’, electrical grounding location.

Additional Graphic Information

Conformité Européenne

Conformity with all legal requirements pertaining

to the equipment with the European Economic

Area.

Hydraulics

Hydraulic fluids must be recycled as required by

local environmental law. Do not dispose of by

adding to the municipal waste stream.

Electric Motor Rotation

Identification of proper electrical motor rotation.

Summary of Contents for 55 Ton

Page 2: ......

Page 41: ...37 55 Ton Exploded View ...

Page 42: ...38 55 Ton Parts List ...

Page 44: ...40 www clevelandsteeltool com 474 E 105th St Cleveland OH 44108 800 446 4402 ...