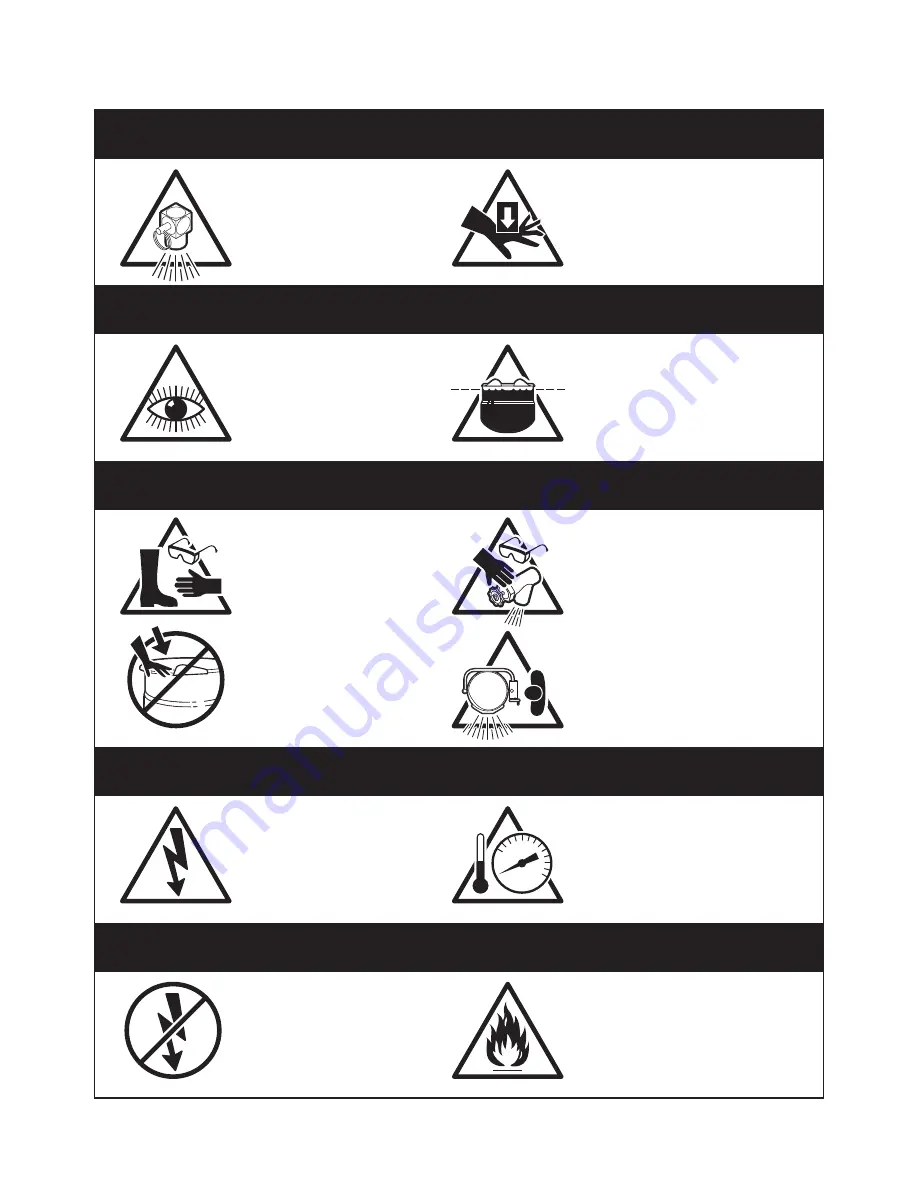

Shut off power at main

fuse disconnect prior

to servicing.

Ensure kettle is at room

temperature and pressure

gauge is showing zero or less

prior to removing any fittings.

Inspect unit daily for

proper operation.

0

Do not fill kettle above

recommended level

marked on outside of kettle.

Surfaces may be

extremely hot! Use

protective equipment.

Keep appliance and area free

and clear of combustibles.

Stand clear of product

discharge path when

discharging hot product.

Wear protective equipment

when discharging hot product.

Do not lean on or place

objects on kettle lip.

Do not attempt to operate

this appliance during a

power failure.

Keep clear of pressure

relief discharge.

Keep hands away from

moving parts and pinch points.

SERVICING

IMPORTANT

CAUTION

DANGER

GAS APPLIANCES

For your safety