8

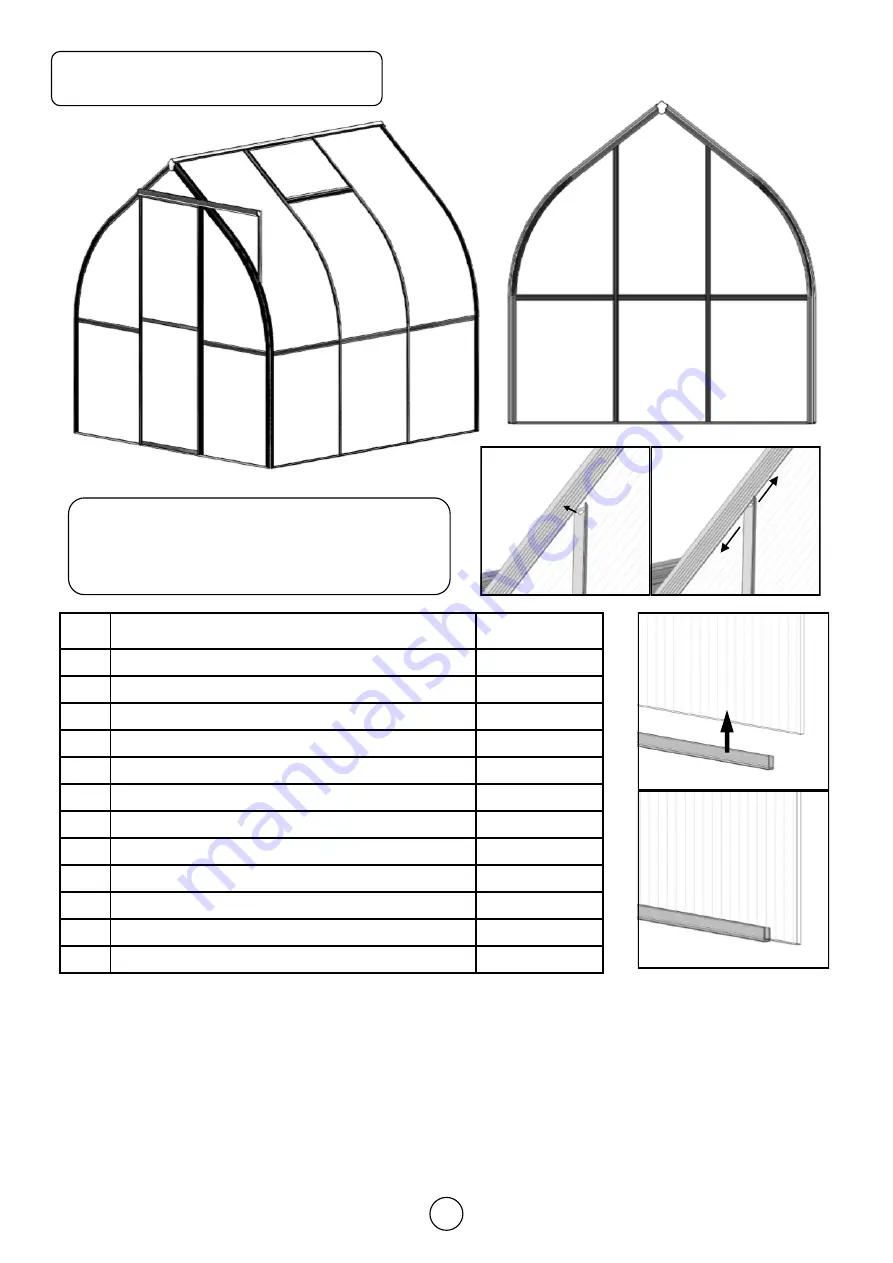

Polycarbonate sheet

#

Size

Spirit V707

A

700x1049

(2’3

9

/

16

” x 3’5

5

/

16

”)

4

B

700x842

(2’3

9

/

16

” x 2’9

1

/

8

”)

10

C

592x16/247/16

(1’11

5

/

16

” x

5

/

8

” / 9

3

/

4

” /

5

/

8

”)

1

D

599x913

(1’11

9

/

16

” x 2’11

15

/

16

”)

2

E

610x1057/1296/1057

(2’ x 3’5

5

/

8

” / 4’3” / 3’5

5

/

8

”)

1

F

610x842

(2’ x 2’9

1

/

8

”)

1

G

700x1157

(2’3

9

/

16

” x 3’9

9

/

16

”)

2

H

696x506

(2’3

3

/

8

” x 1’7

15

/

16

”)

2

I

700x1714

(2’3

9

/

16

” x 5’7

1

/

2

”)

4

p6

592

(1’11

5

/

16

”)

1

p7

682

(2’2

7

/

8

”)

6

p8

660

(2’2”)

4

I

I

G

A

A

A

A

D

D

B

B

B

B

E

F

H

C

p6

p8

p8

p8

p8

p7

p7

p7

p6/p7/p8

p6/p7/p8

B

B

B

This page shows the positioning of the polycarbonate panels for the front and rear gable as

well as the roof and the sides. It also indicates where the gray plastic parts #P6, #P7 and #P8

are used. When fitting parts #P6/P7/P8 on the ends of the panels, try using a narrow piece of

bar soap through the part first. It will allow them to slide on the panel’s edges much easier.

#P6/P7/P8 must be fitted on one end of polycarbonate in advance before polycarbonate is in-

serted into aluminum frame. The square illustration on the page shows the placement of the

gray plastic U shape strips.

Frame

Panel

Bracing bar

Note: If panel edge can’t enter into alumi-

num Frame channel, please use a

bracing bar to squeeze panel edge

into channel.