32

C l i m a t e M a s t e r W a t e r- S o u r c e H e a t P u m p s

C L I M A T E M A S T E R W A T E R - S O U R C E H E A T P U M P S

Tr a n q u i l i t y

®

2 0 ( T S ) S e r i e s

R e v. : 0 6 / 1 7 / 1 5

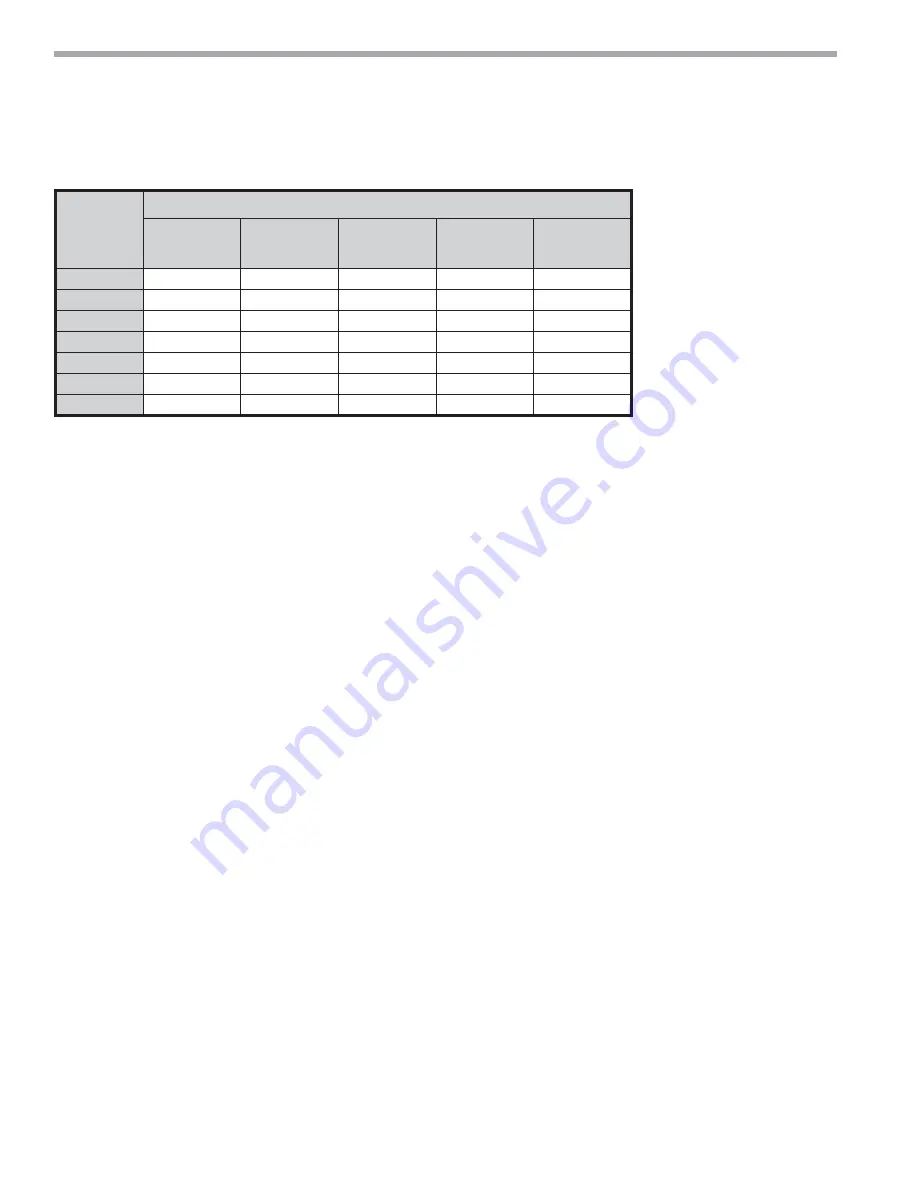

Coil Face

Velocity

FPM

TSH/V/D with Reheat ESP Loss

TSH/V/D

018

In. of Water

TSH/V/D

024, 030

In. of Water

TSH/V/D

036

In. of Water

TSH/V/D

042, 048

In. of Water

TSH/V/D

060, 070

In. of Water

200

0.037

0.033

0.031

0.028

0.026

250

0.052

0.046

0.042

0.038

0.034

300

0.077

0.066

0.059

0.051

0.044

350

0.113

0.096

0.085

0.073

0.061

400

0.181

0.160

0.145

0.131

0.117

450

0.242

0.226

0.215

0.205

0.194

500

0.360

0.345

0.335

0.326

0.316

For TS units with ClimaDry

®

Reheat coil applications, calculate face velocity of the entering air. From the table above,

fi nd ESP for Reheat application. The loss includes wet coil loss.

Example:

Reheat coil loss can be determined from the above table. Coil velocity (FPM) = Airfl ow (CFM) / Face Area (sq. ft.)

1. TSH036 has a face area of 4.86 sq. ft. (see physical data table).

2. At 1,100 cfm, coil velocity (FPM) = 1,100 / 4.86 = 226 FPM

3. From above table, it will be necessary to subtract 0.037 from the blower performance ESP.

4. On medium speed, the TSH036 (without reheat - see blower table) can deliver 1,100 CFM at 0.28 in. wg. with the

standard PSC motor; with the reheat coil, it now delivers 1,085 CFM at 0.28 in. wg. or 1,100 CFM at 0.24 in. wg.

5. If the decrease in airfl ow is acceptable, no changes are necessary. Otherwise, high speed fan should be used to

overcome the pressure drop of the reheat coil.

TS Blower Performance Data - Units with ClimaDry

®

(PSC Motor)

Unit minimum entering air temperature while in the dehumidifi cation, cooling, or continuous fan modes is

70ºF DB/61ºF WB

. Operation below this minimum may result in nuisance faults.