44

C l i m a t e M a s t e r W a t e r- S o u r c e H e a t P u m p s

C L I M A T E M A S T E R W A T E R - S O U R C E H E A T P U M P S

Tr a n q u i l i t y

®

2 0 ( T S ) S e r i e s

R e v. : 0 6 / 1 7 / 1 5

ClimaDry

®

Sequence Of Operation

A heat pump equipped with ClimaDry

®

can operate

in three modes, cooling, cooling with reheat, and

heating. The cooling/heating modes are like any other

ClimateMaster WSHP. The reversing valve (“O” signal)

is energized in cooling, along with the compressor

contactor(s) and blower relay. In the heating mode the

reversing valve is de-energized. Almost any thermostat

will activate the heat pump in heating or cooling modes.

The DXM microprocessor board, which is standard with

the ClimaDry

®

option, will accept either heat pump (Y,O)

thermostats or non-heat pump (Y,W) thermostats.

The reheat mode requires either a separate humidistat/

dehumidistat or a thermostat that has an integrated

dehumidifi cation function for activation. The DXM

board is confi gured to work with either a humidistat or

dehumidistat input to terminal “H” (DIP switch settings

for the DXM board are shown in table 6). Upon receiving

an “H” input, the DXM board will activate the cooling

mode and engage reheat. Table 7 shows the relationship

between thermostat input signals and unit operation.

There are four operational inputs for single stage units

and six operational inputs for dual stage units:

-Fan Only

-1st Stage Cooling

-2nd Stage Cooling

-1st Stage Heating

-2nd Stage Heating

-Reheat Mode

• Fan Only:

A (G) call from the thermostat to the (G

terminal of the DXM control board will bring the unit

on in fan only mode.

• 1st Stage Cooling:

A simultaneous call from (G),

(Y1), and (O) to the (G), (Y1), (O/W2) terminals of the

DXM control board will bring the unit on in 1st Stage

Cooling.

• 2nd Stage Cooling:

A simultaneous call from (G),

(Y1), (Y2), and (O) to the (G), (Y1), (Y2), and (O/W2)

terminals of the DXM control board will bring the unit

on in 2nd Stage Cooling. When the call is satisfied

at the thermostat the unit will continue to run in 1st

Stage Cooling until the 1st Stage Cooling call is

removed or satisfied, shutting down the unit.

Note:

Not all units have two-stage cooling functionality

(e.g. GC series units).

• 1st Stage Heating:

A simultaneous call from (G) and

(Y1) to the (G) and (Y1) terminals of the DXM control

board will bring the unit on in 1st Stage Heating.

• 2nd Stage Heating:

A simultaneous call from (G),

(Y1), and (Y2) to the (G), (Y1), and (Y2) terminals of the

DXM control board will bring the unit on in 2nd Stage

Heating. When the call is satisfied at the thermostat

the unit will continue to run in 1st Stage Heating

until the call is removed or satisfied, shutting down

the unit. NOTE: Not all units have two-stage heating

functionality.

• Reheat Mode

: A call from the Humidistat/

Dehumidistat to the (H) terminal of the DXM control

board will bring the unit on in Reheat Mode if there

is no call for cooling at the thermostat. When the

Humidistat Dehumidification call is removed or

satisfied the unit will shut down. Note: Cooling always

overrides Reheat Mode. In the Cooling mode, the unit

cools and dehumidifies. If the cooling thermostat is

satisfied but there is still a call for dehumidification,

the unit will continue to operate in Reheat Mode.

ClimaDry

®

Component Functions

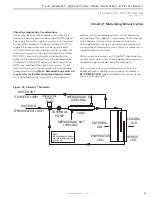

The ClimaDry

®

option consists of the following

components:

• Proportional Controller

• Supply Air Sensor

• Motorized Valve

• Loop Pump

• Hydronic Coil

The Proportional Controller operates on 24 VAC power

supply and automatically adjusts the water valve based

upon the Supply Air Sensor. The Supply Air Sensor

senses supply air temperature at the blower inlet

providing the input signal necessary for the proportional

control to drive the motorized valve during the reheat

mode of operation. The Motorized Valve is a proportional

actuator/three-way valve combination used to divert

the condenser water from the coax to the hydronic

reheat coil during the reheat mode of operation. The

proportional controller sends a signal to the motorized

valve based on the supply air temperature of the supply

air sensor.

The Loop Pump circulates condenser water through

the hydronic reheat coil during the reheat mode of

operation. In this application, the loop pump is only

energized during the reheat mode of operation. The

Hydronic Coil is utilized during the reheat mode of

operation to reheat the air to the setpoint of the

proportional controller. Condenser water is diverted by

the motorized valve and pumped through the hydronic

coil by the loop pump in proportion to the control

setpoint. The amount of reheating is dependent on

the setpoint and how far from setpoint the supply air

temperature is. The factory setpoint is 72°F [22.2°C],

generally considered “neutral” air.

ClimaDry

®

Modulating Reheat Option