17

c l i m a t e m a s t e r. c o m

Tranquility

®

30 Digital (TE) Series IOM - 60Hz HFC-410A

R e v. : 2 9 M a y, 2 0 1 5 J

Multiple Unit Piping and Flushing

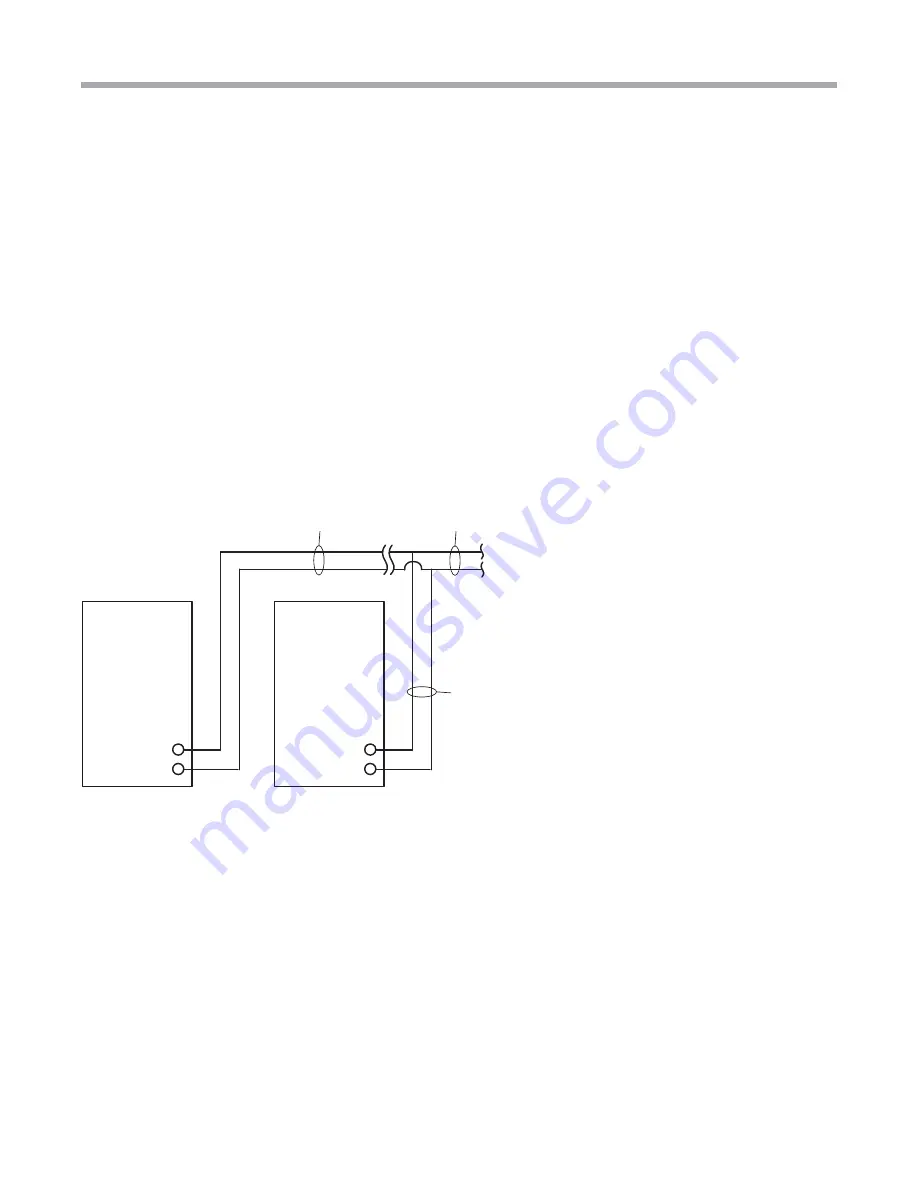

Figure 16a: Multiple Units with Internal Flow Controllers

Multiple Units with Internal Flow Controllers

The simplest multiple unit system is one with two (or more) units utilizing internal Flow Controllers with no external pumps

or

fl

ushing valves. In this case the units are piped in parallel and use the internal

fl

ushing valves to

fl

ush the system. The

variable speed pump includes an internal check valve to prevent back (short circuiting)

fl

ow through the units.

In this case,

fl

ush the loop through the internal

fl

ushing valves in the unit farthest from the loop

fi

rst. Once the loop is

fl

ushed,

then change the internal

fl

ushing valves to

fl

ush the heat pump. Next, move the

fl

ushing cart to the next closest unit to the

loop.

Again,

fl

ush the loop through the internal

fl

ushing valves. This is important as there may be air/debris in the lines from this unit

to the common piping. Once

fl

ushing begins the air will be move into the loop and will need to be

fl

ushed out. After the loop

is

fl

ushed through the second unit, change the

fl

ushing valves to

fl

ush the second unit. This process should be repeated for

additional units working from the farthest from the loop to the closest to the loop.

This type of application can generally be employed for systems to 12 tons depending on loop design. However, it is important

perform appropriate calculations to con

fi

rm that the variable speed pump can provide adequate

fl

ow through all heat pumps

against the loop head when all units are operating.

Multiple Units with Internal Flow Controllers and External Flushing Valves

When the number of units or

fl

ushing requirements reaches a point where it is no longer feasible to

fl

ush through the internal

valves (generally systems of more than 12 tons depending on loop design), external

fl

ushing valves should be installed. In this

case, three-way

fl

ushing valves should be used or additional isolation valves must be installed to be able to isolate the loop

during

fl

ushing.

First,

fl

ush the ground loop. The installer should close the indoor loop shut-off valve (or the internal

fl

ushing valves in all units)

and open the ground loop shut-off valve to prevent

fl

ow through the indoor loop while

fl

ushing the ground loop.

Once the ground loop is

fl

ushed, close the ground loop shut-off valve and open the indoor loop valve(s) to

fl

ush the units and

indoor piping. Remember that there is an internal check valve in the variable speed pump and that backward

fl

ow the unit is

not possible.

Water Out

Water In

Heat Pump

B

Water Out

Water In

Heat Pump

A

To Ground

Loop

Size for Heat Pump

‘A’ Flow

Size for Heat Pump

‘B’ Flow

Size for ‘A’ + ‘B’ Flow