33

c l i m a t e m a s t e r. c o m

Tranquility

®

30 Digital (TE) Series IOM - 60Hz HFC-410A

R e v. : 2 9 M a y, 2 0 1 5 J

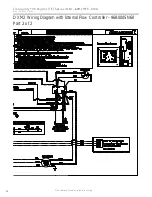

DXM2 Wiring Diagram with Motorized Modulating Water Valve -

96B0005N62 - Part 1 of 2

This diagram includes typical wiring details but is not applicable to all units. For speci

fi

c unit wiring, refer to the diagram or the

units’ control panel.