52

G e o t h e r m a l H e a t i n g a n d C o o l i n g

Tranquility

®

30 Digital (TE) Series IOM - 60Hz HFC-410A

R e v. : 2 9 M a y, 2 0 1 5 J

WARNING!

HAZARDOUS VOLTAGE! DISCONNECT

ALL ELECTRIC POWER INCLUDING REMOTE

DISCONNECTS BEFORE SERVICING.

Failure to disconnect power before servicing can cause

severe personal injury or death.

WARNING!

Troubleshooting

Outputs

The compressor and reversing valve relays are 24VAC

and can be veri

fi

ed using a voltmeter. For units with ECM

blower motors, the DXM2 controls the motor using serial

communications, and troubleshooting should be done with

a communicating thermostat or diagnostic tool. The alarm

relay can either be 24VAC as shipped or dry contacts for use

with DDC controls by clipping the JW1 jumper. Electric heat

outputs are 24VDC “ground sinking” and require a voltmeter

set for DC to verify operation. The terminal marked “24VDC”

is the 24VDC supply to the electric heat board; terminal

“EH1” is stage 1 electric heat; terminal “EH2” is stage 2

electric heat. When electric heat is energized (thermostat

is sending a “W” input to the DXM2 controller), there will

be 24VDC between terminal “24VDC” and “EH1” (stage 1

electric heat) and/or “EH2” (stage 2 electric heat). A reading

of 0VDC between “24VDC” and “EH1” or “EH2” will indicate

that the DXM2 board is NOT sending an output signal to the

electric heat board.

Test Mode

Test mode can be entered for 20 minutes by pressing the

Test pushbutton. The DXM2 board will automatically exit test

mode after 20 minutes.

Advanced Diagnostics

To properly troubleshoot advanced control features,

and to aid in troubleshooting basic control features, a

communicating thermostat or diagnostic tool must be used.

Service Mode

The Service Mode provides the installer with several

functions for troubleshooting, including Manual Operation,

Control Diagnostics, Control Con

fi

guration, and Fault

History.

Manual Operation – The Manual Operation mode allows the

installer to bypass normal thermostat timings and operating

modes, to directly activate the thermostat inputs to the

DXM2, activate the DXM2 Test mode, and directly control the

ECM blower, internal

fl

ow center, and proportional valve.

Control Diagnostics – The Control Diagnostics menus allow

the installer to see the current status of all DXM2 control

switch inputs, values of all temperature sensor inputs,

control voltage, ECM blower, internal

fl

ow center, and

proportional valve operating status and parameters.

Dipswitch Con

fi

guration – The Dipswitch Con

fi

guration

menus allow the installer to easily see the current DXM2

control con

fi

guration.

Fault History – In addition to the fault code, the DXM2 stores

the status of all control inputs and outputs when a fault

condition is detected. The fault history covering the last

fi

ve

lockout conditions is stored and may be retrieved from the

DXM2. After a speci

fi

c fault in the fault history is selected,

the operating mode and time when the fault occurred are

displayed, with options to select speci

fi

c control status

values when the lockout occurred.

Fault Temp Conditions – This option displays the DXM2

temperature and voltage values when the lockout occurred.

Fault Flow Conditions – This option displays the DXM2 ECM

blower, pump, and valve operating parameters when the

lockout occurred.

Fault I/O Conditions – This option displays the status of

the DXM2 physical and communicated inputs and the relay

outputs when the lockout occurred.

Fault Con

fi

guration Conditions – This option displays the

status of the DXM2 option selections when the lockout

occurred.

Fault Possible Causes – This option displays a list of

potential causes of the stored fault.

Clear Fault History – The Clear Fault History option allows

the fault history stored in the non-volatile memory of the

DXM2 to be cleared.

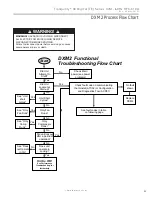

DXM2 Troubleshooting Process Flowchart/Functional

Troubleshooting Chart

The “DXM2 Functional Troubleshooting Process Flowchart”

is a quick overview of how to start diagnosing a suspected

problem, using the fault recognition features of the DXM2

board. The “Functional Troubleshooting Chart” on the

following page is a more comprehensive method for

identifying a number of malfunctions that may occur, and is

not limited to just the DXM2 controls. Within the chart are

fi

ve columns:

• The “Fault” column describes the symptoms.

• Columns 2 and 3 identify in which mode the fault is likely

to occur, heating or cooling.

• The “Possible Cause column” identi

fi

es the most likely

sources of the problem.

• The “Solution” column describes what should be done to

correct the problem.