CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Tranquility

®

(TRL) Series

R e v. : N o v e m b e r 1 1 , 2 0 2 1

C l i m a t e M a s t e r Wa t e r-S o u rc e H e a t P u m p s

56

Unit Start-Up Procedure

Unit Start-up Procedure

1. Turn the thermostat fan position to

“ON”. Blower should start.

2.

Balance air flow at registers.

3. Adjust all valves to their full open

positions. Turn on the line power to

all heat pumps.

4. Room temperature should be within

the minimum-maximum ranges

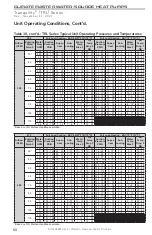

of Tables 7 and 8. During start-up

checks, loop water temperature

entering the heat pump should be

between 60°F [16°C] and 95°F [35°C].

5. Two factors determine the operating

limits of ClimateMaster heat pumps,

(a) return air temperature/flow, and

(b) water temperature/flow. When

any one of these factors is at a

minimum or maximum level, the

other factor must be at normal level

to ensure proper unit operation.

a. Adjust the unit thermostat to

the warmest setting. Place the

thermostat mode switch in the

“COOL” position. Slowly reduce

thermostat setting until the

compressor activates.

b. Check for cool air delivery at the

unit grille within a few minutes

after the unit has begun to

operate.

Note: Units have a five minute

time delay in the control

circuit that can be eliminated

on the CXM2 control board as

shown below in Figure 18. See

controls description for details.

c. Verify that the compressor is on

and that the water flow rate is

correct by measuring pressure

drop through the heat exchanger

using the P/T plugs & comparing

to Table 9. The unit must have

enough flow as per the flow

switch setpoint in order for the

compressor to start.

d. Check the elevation and

cleanliness of the condensate

lines. Dripping may be a sign

of a blocked line. Check that

the condensate trap is filled to

provide a water seal.

e. Refer to Table 7 and 8. Check

the temperature of both

entering and leaving water. If

temperature is within range,

proceed with the test. Verify

correct water flow by comparing

unit pressure drop across the

heat exchanger versus the data

in Table 9. Heat of rejection

(HR) can be calculated and

compared to submittal data

capacity pages. The formula for

HR for systems with water is as

follows:

HR (Btuh) = TD x GPM

x 500,where TD is the

temperature difference between

the entering and leaving water,

and GPM is the flow rate in U.S.

GPM, determined by comparing

the pressure drop across the

heat exchanger to Table 9. In S-I

units, the formula is as follows:

HR (kW) = TD x l/s x 4.18.

f. Check air temperature drop

across the air coil when

compressor is operating. Air

temperature drop should be

between 15

°

F and 25

°

F [8°C

and 14°C].

g. Turn thermostat to “OFF”

position. A hissing noise

indicates proper functioning of

the reversing valve.

6.

Allow five (5) minutes between

tests for pressure to equalize before

beginning heating test.

a. Adjust the thermostat to the

lowest setting. Place the

thermostat mode switch in the

“HEAT” position.