10

C l i m a t e M a s t e r Wa t e r- S o u rc e H e a t P u m p s

C L I M A T E M A S T E R W A T E R - S O U R C E H E A T P U M P S

Tr a n q u i l i t y

®

3 0 ( T T ) S e r i e s

R e v. : 0 7 / 1 8 / 1 3

ರ

ರ

ರ

* Some units include a painted drain connection.

Using a threaded pipe or similar device to clear

any excess paint accumulated inside this fitting

may ease final drain line installation.

ರ3HU

)RRW

Horizontal Installation

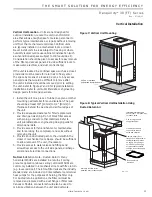

Figure 6: Horizontal Condensate Connection

CAUTION!

Ensure condensate line is pitched toward drain

1/8 inch per ft [11mm per m] of run.

Condensate Piping

- Horizontal Units -

A condensate

drain line must be installed and pitched away for the unit

to allow for proper drainage. This connection must meet

all local plumbing/building codes.

Pitch the unit toward the drain as shown in Figure 2 to

improve the condensate drainage. On small units (less

than 2.5 tons/8.8 kW), ensure that unit pitch does not

cause condensate leaks inside the cabinet.

Install condensate trap at each unit with the top of

the trap positioned below the unit condensate drain

connection as shown in Figure 6. Design the depth of

the trap (water-seal) based upon the amount of ESP

capability of the blower (where 2 inches [51mm] of ESP

capability requires 2 inches [51mm] of trap depth).

As a general rule, 1-1/2 inch [38mm] trap depth is the

minimum.

Each unit must be installed with its own individual trap

and connection to the condensate line (main) or riser.

Provide a means to fl ush or blow out the condensate line.

DO NOT install units with a common trap and/or vent.

Always vent the condensate line when dirt or air

can collect in the line or a long horizontal drain line

is required. Also vent when large units are working

against higher external static pressure than other units

connected to the same condensate main since this may

cause poor drainage for all units on the line.

WHEN A

VENT IS INSTALLED IN THE DRAIN LINE, IT MUST BE

LOCATED AFTER THE TRAP IN THE DIRECTION OF

THE CONDENSATE FLOW.

CAUTION!

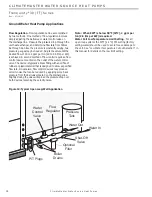

Duct System Installation

- Proper duct sizing and design

is critical to the performance of the unit. The duct system

should be designed to allow adequate and even airfl ow

through the unit during operation. Air fl ow through

the unit MUST be at or above the minimum stated

airfl ow for the unit to avoid equipment damage. Duct

systems should be designed for quiet operation. Refer

to Figure 3 for horizontal duct system details or Figure

8 for vertical duct system details. A fl exible connector

is recommended for both discharge and return air duct

connections on metal duct systems to eliminate the

transfer of vibration to the duct system. To maximize

sound attenuation of the unit blower, the supply and

return plenums should include internal fi berglass duct

liner or be constructed from ductboard for the fi rst few

feet. Application of the unit to uninsulated ductwork in an

unconditioned space is not recommended, as the unit’s

performance may be adversely affected.

At least one 90° elbow should be included in the supply

duct to reduce air noise. If air noise or excessive air fl ow

is a problem, the blower speed can be changed. For

airfl ow charts, consult submittal data for the series and

model of the specifi c unit.

If the unit is connected to existing ductwork, a previous

check should have been made to ensure that the

ductwork has the capacity to handle the airfl ow required

for the unit. If ducting is too small, as in the replacement

of a heating only system, larger ductwork should be

installed. All existing ductwork should be checked for

leaks and repaired as necessary.

Condensate Piping

R e v. : 0 7 / 1 8 / 1 3

R e v. : 0 7 / 1 8 /

Duct System Installation