34

C l i m a t e M a s t e r Wa t e r- S o u rc e H e a t P u m p s

C L I M A T E M A S T E R W A T E R - S O U R C E H E A T P U M P S

Tr a n q u i l i t y

®

3 0 ( T T ) S e r i e s

R e v. : 0 7 / 1 8 / 1 3

DXM Controls

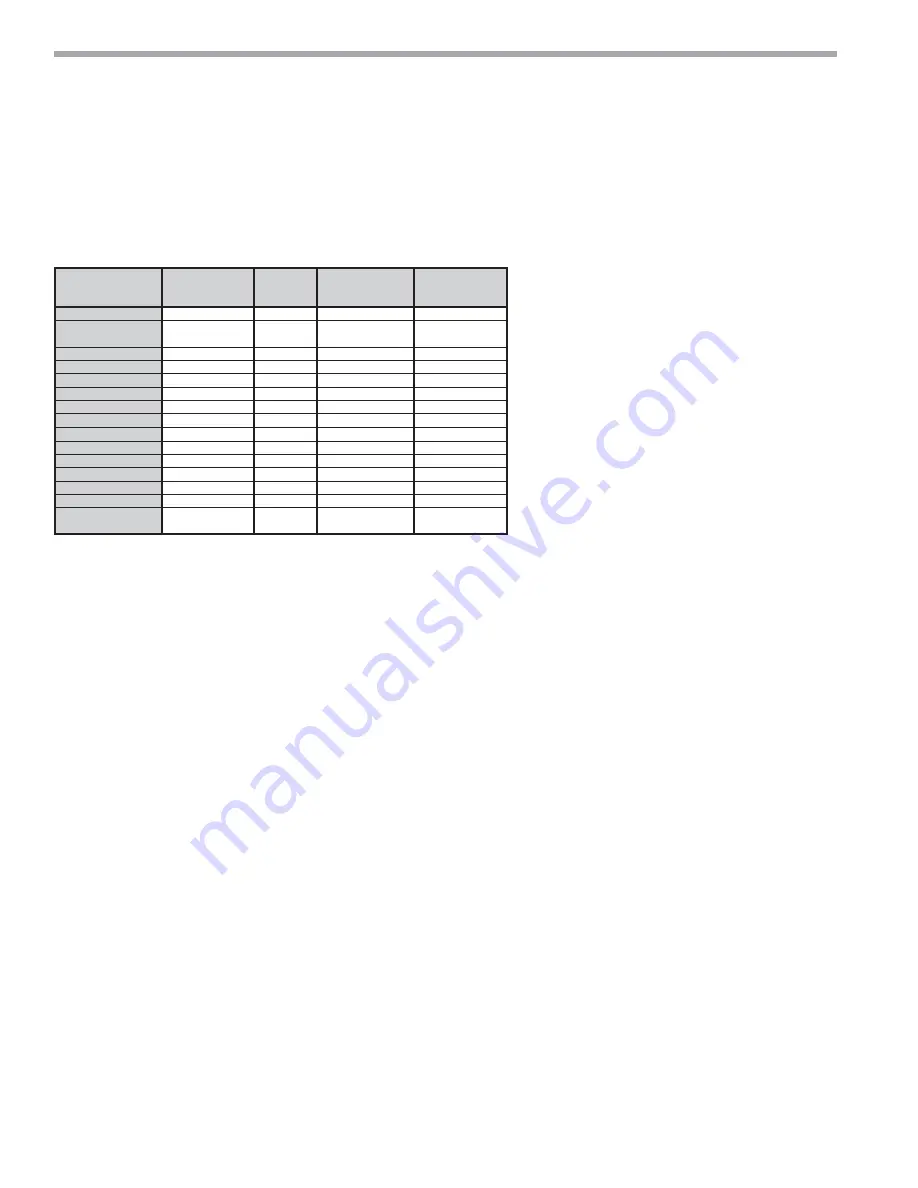

Table 6b: DXM LED And Alarm Relay Operations

DXM Control -

For detailed control information, see

DXM AOM (part #97B0003N13), Lon controller AOM (part

#97B0013N01) or MPC AOM (part # 97B0031N01).

-Slow Flash = 1 fl ash every 2 seconds

-Fast Flash = 2 fl ashes every 1 second

-Flash code 2 = 2 quick fl ashes, 10 second pause, 2 quick

fl ashes, 10 second pause, etc.

-On pulse 1/3 second; off pulse 1/3 second

Field Selectable Inputs -

Test mode: Test mode allows

the service technician to check the operation of the

control in a timely manner. By momentarily shorting the

test terminals, the DXM control enters a 20 minute test

mode period in which all time delays are sped up 15

times. Upon entering test mode, the status LED will fl ash

a code representing the last fault. For diagnostic ease at

the thermostat, the alarm relay will also cycle during test

mode. The alarm relay will cycle on and off similar to the

status LED to indicate a code representing the last fault,

at the thermostat. Test mode can be exited by shorting

the test terminals for 3 seconds.

Retry mode:

If the control is attempting a retry of a fault,

the status LED will slow fl ash (slow fl ash = one fl ash every

2 seconds) to indicate the control is in the process of

retrying.

Field Confi guration Options -

Note: In the following

fi eld confi guration options, jumper wires should be

clipped ONLY when power is removed from the DXM

control.

Water coil low temperature limit setting:

Jumper

3 (JW3-LT1 Low Temp) provides fi eld selection of

temperature limit setting for LT1 of 30°F or 10°F [-1°F or

-12°C] (refrigerant temperature).

Not Clipped = 30°F [-1°C]. Clipped = 10°F [-12°C].

Air coil low temperature limit setting: Jumper 2 (JW2-LT2

Low Temp) provides fi eld selection of temperature limit

setting for LT2 of 30°F or 10°F [-1°F or -12°C]

(refrigerant temperature).

Note: This jumper

should only be clipped under extenuating

circumstances, as recommended by

ClimateMaster technical services.

Not Clipped = 30°F [-1°C]. Clipped = 10°F

[-12°C].

Alarm relay setting:

Jumper 4 (JW4-AL2 Dry)

provides fi eld selection of the alarm relay

terminal AL2 to be jumpered to 24VAC or to be

a dry contact (no connection).

Not Clipped = AL2 connected to R.

Clipped = AL2 dry contact (no connection).

Low pressure normally open:

Jumper 1 (JW1-

LP norm open) provides fi eld selection for low

pressure input to be normally closed or normally

open.

Not Clipped = LP normally closed. Clipped = LP normally

open.

DIP Switches - Note: In the following fi eld

confi guration options, DIP switches should only be

changed when power is removed from the DXM

control.

DIP Package #1 (S1) -

DIP Package #1 has 8 switches

and provides the following setup selections:

1.1

- Unit Performance Sentinel (UPS) disable: DIP Switch

1.1 provides fi eld selection to disable the UPS feature.

On = Enabled. Off = Disabled.

1.2 -

Compressor relay staging operation: DIP 1.2

provides selection of compressor relay staging operation.

The compressor relay can be selected to turn on with

a stage 1 or stage 2 call from the thermostat. This

is used with dual stage units (2 compressors where

2 DXM controls are being used) or with master/

slave applications. In master/slave applications,

each compressor and fan will stage according to

its appropriate DIP 1.2 setting. If set to stage 2, the

compressor will have a 3 second on-delay before

energizing during a Stage 2 demand. Also, if set for stage

2, the alarm relay will NOT cycle during test mode.

On = Stage 1. Off = Stage 2.

1.3 -

Thermostat type (heat pump or heat/cool): DIP 1.3

provides selection of thermostat type. Heat pump or

heat/cool thermostats can be selected. When in heat/

cool mode, Y1 is the input call for cooling stage 1; Y2 is

the input call for cooling stage 2; W1 is the input call for

heating stage 1; and O/W2 is the input call for heating

Description of

Operation

Status LED

(green)

Test LED

(yellow)

Fault LED

(red)

Alarm Relay

Normal mode

On

-

Off

Open

Normal mode with UPS

On

-

Flashing Code 8

Cycle (closed 5 sec,

open 25 sec)

DXM is non-functional

Off

Off

Off

Open

Fault Retry

Slow Flash

-

Flashing fault code

Open

Lockout

Fast Flash

-

Flashing fault code

Closed

Test Mode

-

On

-

-

Night Setback

Flashing Code 2

-

-

-

ESD

Flashing Code 3

-

-

-

HP Fault

Slow Flash

-

Flashing Code 2

Open

LP Fault

Slow Flash

-

Flashing Code 3

Open

LT1 Fault

Slow Flash

-

Flashing Code 4

Open

LT2 Fault

Slow Flash

-

Flashing Code 5

Open

CO Fault

Slow Flash

-

Flashing Code 6

Open

Over/Under Voltages

Slow Flash

-

Flashing Code 7

Open (closed after 15

minutes)

Invalid T-stat Inputs

Flashing Code 4

-

-

-