36

C l i m a t e M a s t e r W a t e r- S o u r c e H e a t P u m p s

C L I M A T E M A S T E R W A T E R - S O U R C E H E A T P U M P S

Tr a n q u i l i t y

®

2 2 ( T Z ) S e r i e s

R e v i s e d : 0 1 / 2 1 / 1 3

DXM2 Controls

1.6

– DDC output at EH2: DIP 1.6 provides selection

for DDC operation. If set to “DDC Output at EH2,”

the EH2 terminal will continuously output the last fault

code of the controller. If set to “EH2 normal,” EH2 will

operate as standard electric heat output.

On = EH2 Normal. Off = DDC Output at EH2.

1.7

– Boilerless operation: DIP 1.7 provides selection

of boilerless operation. In boilerless mode, the

compressor is only used for heating when LT1 is above

the temperature specifi ed by the setting of DIP 1.8.

Below DIP 1.8 setting, the compressor is not used and

the control goes into emergency heat mode, staging

on EH1 and EH2 to provide heating.

On = normal. Off = Boilerless operation.

1.8

– Boilerless changeover temperature: DIP

1.8 provides selection of boilerless changeover

temperature setpoint. Note that the LT1 thermistor is

sensing refrigerant temperature between the coaxial

heat exchanger and the expansion device (TXV).

Therefore, the 50°F [10°C] setting is not 50°F [10°C]

water, but approximately 60°F [16°C] EWT.

On = 50°F [10°C]. Off = 40°F [16°C].

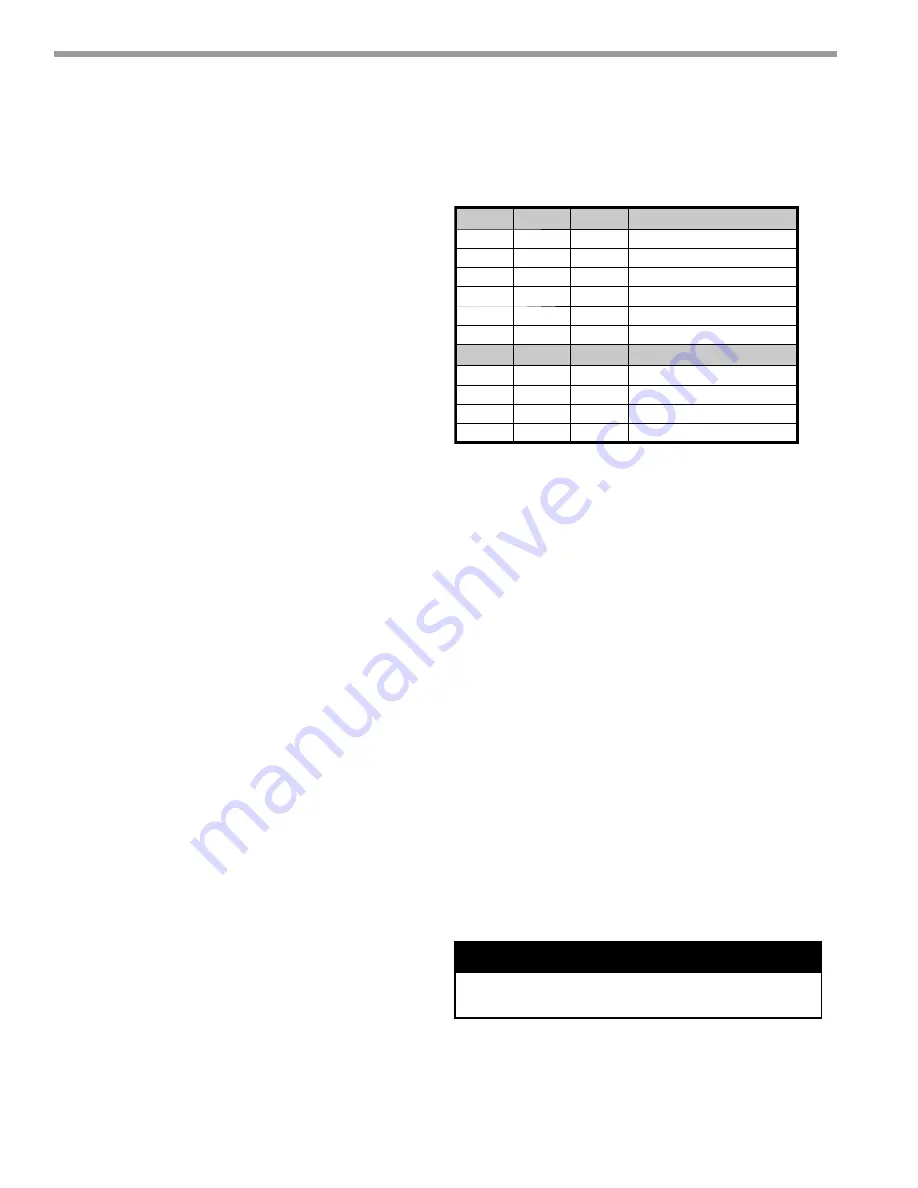

DIP Package #2 (S2)

– A combination of dip switches

2.1, 2.2, 2.3, and 2.4, 2.5, 2.6 deliver confi guration of

ACC1 and ACC2 relay options respectively. See Table

7a for description and functionality

.

2.7

– Auto dehumidifi cation fan mode or high

fan mode: DIP 2.7 provides selection of auto

dehumidifi cation fan mode or high fan mode. In auto

dehumidifi cation mode, the fan speed relay will remain

off during cooling stage 2 IF the H input is active. In

high fan mode, the fan enable and fan speed relays will

turn on when the H input is active.

On = Auto dehumidifi cation mode (default). Off = High

fan mode.

2.8

– Special factory selection: DIP 2.8 provides special

factory selection. Normal position is “On”. Do not

change selection unless instructed to do so by the

factory.

Table 7a: Accessory DIP Switch Settings

DIP Package #3 (S3)

– DIP Package #3 has 4 switches and provides the

following setup and operating selections:

3.1

– Communications confi guration: DIP 3.1 provides

selection of the DXM2 operation in a communicating

system. The DXM2 may operate as the Master of certain

network confi gurations. In most confi gurations the

DXM2 will operate as a master device.

On = Communicating Master device (default). Off =

communicating Slave device.

3.2

– HWG Test Mode: DIP 3.2 provides forced operation

of the HWG pump output, activating the HWG pump

output for up to fi ve minutes.

On = HWG test mode. Off = Normal HWG mode

(default).

3.3

– HWG Temperature: DIP 3.3 provides the selection

of the HWG operating setpoint.

On = 150°F [66°C]. Off = 125°F [52°C] (default).

3.4

– HWG Status: DIP 3.4 provides HWG operation

control.

On = HWG mode enabled. Off = HWG mode disabled

(default).

CAUTION!

CAUTION!

Do not restart units without inspection and

remedy of faulting condition. Equipment damage may occur.

DIP 2.1 DIP 2.2 DIP 2.3

ACC1 Relay Option

On

On

On

Cycle with fan

Off

On

On

Digital NSB

On

Off

On

Water Valve - slow opening

On

On

Off

OAD

Off

Off

Off

Reheat Option - Humidistat

Off

On

Off

Reheat Option - Dehumidistat

DIP 2.4 DIP 2.5 DIP 2.6

ACC2 Relay Option

On

On

On

Cycle with compressor

Off

On

On

Digital NSB

On

Off

On

Water Valve - slow opening

On

On

Off

OAD

(SSV[OLY+07JVTIPUH[PVUZHYLPU]HSPK