39

c l i m a t e m a s t e r. c o m

T H E S M A R T S O L U T I O N F O R E N E R G Y E F F I C I E N C Y

Tr a n q u i l i t y

®

2 2 ( T Z ) S e r i e s

R e v i s e d : 0 1 / 2 1 / 1 3

Conventional

T-stat signal

(Non-Communicating)

Unit

ECM fan

G

Fan only

G, Y1

Stage 1 heating

1

G, Y1, Y2

Stage 2 heating

1

G, Y1, Y2, W

Stage 3 heating

1

G, W

Emergency heat

G, Y1, O

Stage 1 cooling

2

G, Y1, Y2, O

Stage 2 cooling

2

1

Stage 1 = 1st stage compressor, 1st stage fan operation

Stage 2 = 2nd stage compressor, 2nd stage fan operation

Stage 3 = 2nd stage compressor, auxiliary electric heat, 3rd stage fan operation

2

Stage 1 = 1st stage compressor, 1st stage fan operation, reversing valve

Stage 2 = 2nd stage compressor, 2nd stage fan operation, reversing valve

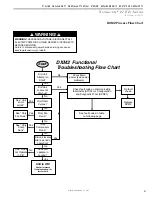

DXM2 Controls

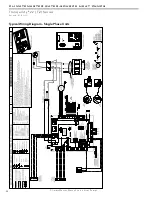

Figure 26b: Test Mode Button

Table 7c: Unit Operation

DXM2 Control Start-up Operation

– The control will not

operate until all inputs and safety controls are checked

for normal conditions. The compressor will have a 5

minute anti-short cycle delay at power-up. The fi rst time

after power-up that there is a call for compressor, the

compressor will follow a 5 to 80 second random start delay.

After the random start delay and anti-short cycle delay,

the compressor relay will be energized. On all subsequent

compressor calls, the random start delay is omitted.

(240Vac)

Com

N.O.

Fan Enable

Test

P5

B-

Gnd

P4

A+ 24V

(240Vac)

Fan Speed

N.O.

N.C.

12V

OUT

Gnd

P8

IN

NC

P12

Pust test button to enter Test

Mode and speed-up timing and

delays for 20 minutes.