HRAT E - HRAT/HRAN

12

English 09/02

U N

N4

L2

U3

U1

A1

1 0

12VAC

230VAC

0

14

21 22

12VAC

12VAC

POWER

3

2

C

1

R1

15

16

KM1

18

15

FU2

17

12DC

TK

ID3

ST1

ST2

ST3

ST4

GND

ALL

GND

ALARM

ANALOG INPUT

DIGITAL INPUT

1

E

3

4

2

6

7

8

9

14

15

F3

SA1

SA2

3

F

1

2

4

5

6

10

11

+to

BT1

+to

BT2

+po

BP3

bianco

marrone

RD1

230/24VAC 500mA MAX

1

R2

DIGITAL OUTPUT

D

5

6

YV1

KA2

KM1

1~

M

16

17

E1

KA2

1~

M

A

1

2

3

4

5

6

7

EV1

U1

Z1

U2

Z2

15

KA1

1

2

3

KEYB

26

24

25

A2

5

6

4

24VAC

230VAC

3

TC1

19

20

18

A6

KA1

4

5

5

6

17

33

15

42

42

33

4

0

3

3

0

0

3

3

42

33

0

20

0

19

21

22

30

32

33

35

36

38

39

40

41

42

FU1

FU4

32

42

34

32

33

30

KA1

35

36

17

44

15

37

42

36

42

39

42

40

30

38

42

39

40

38

41

42

27

27

28

28

23

23

24

24

25

26

47

46

45

25

29

45

46

47

15

23

15

24

15

2

17

3

4

5

6

C2

1 0

26

18

15

23

24

15

7

8

3

9

27

28

27

28

ID4

37

34

ID5

34

F5

ID1

F1

F2

ID2

32

33

42

36

44

34

30

39

40

38

41

42

45

46

47

33

15

42

30

42

20

0

MORSETTI PER INSTALLATORE

INSTALLATOR TERMINAL BOX

42

41

FU3

2

2

3

4

0

3

3

0

2

U-V-W-N

PE

230V~50Hz

QF1

U-N

L-N

1

1~

M

2

3

CS

R

KM1

Z1

1

C1

QM1

QS1

UN

45

46

47

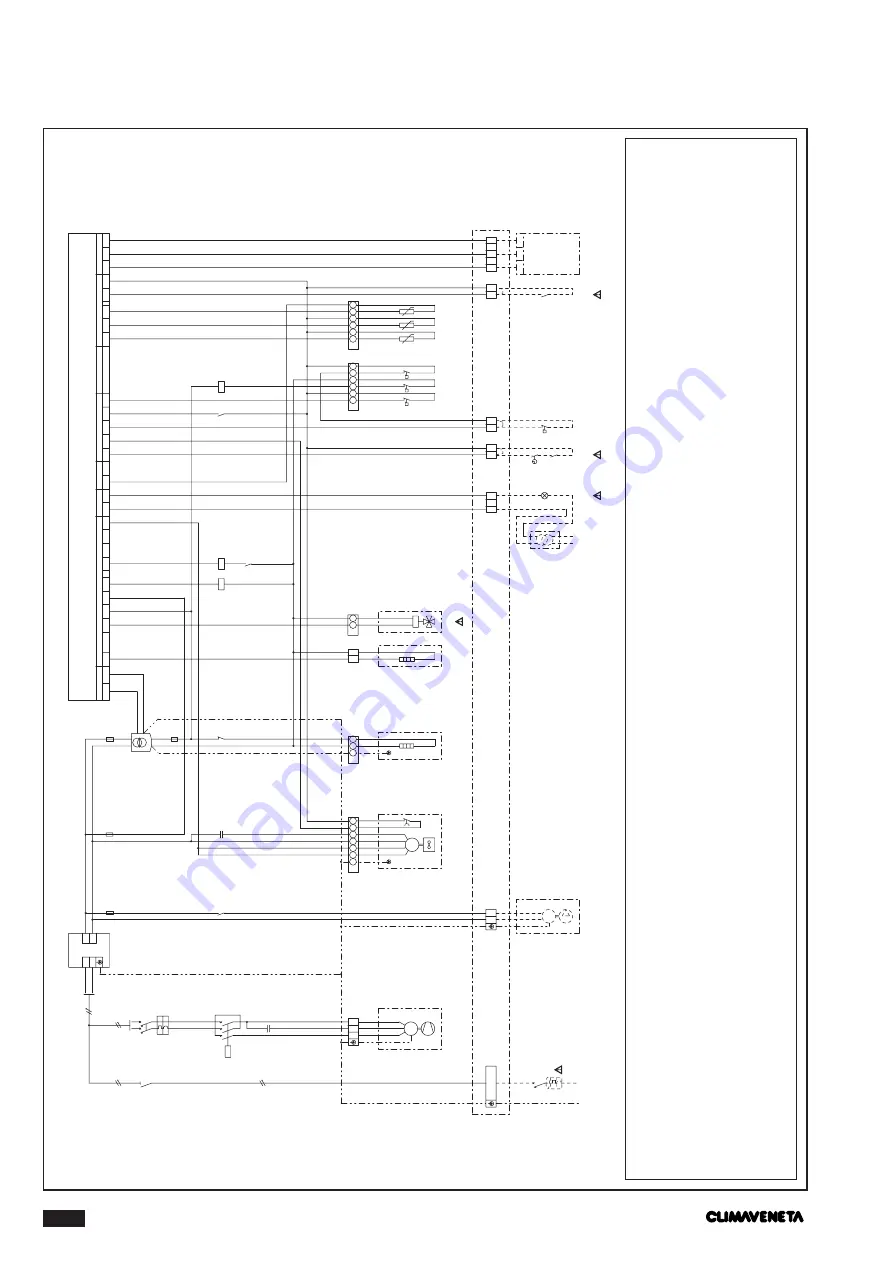

WIRING DIAGRAM 0011-0021 SINGLE PHASE

F

actor

y installed components

A1

Radio interf

er

ence suppr

esser

A2

Electr

onic contr

oller

A6

Unit contr

ol displa

y k

eyboar

d

BP3

Condensing/e

va

poration contr

ol pr

essur

e transducer

BT1

Installation water inlet temperatur

e sensor

BT2

Installation water outlet temperatur

e sensor

C1

Compr

essor star

t ca

pacitor

C2-3

Fan star

t ca

pacitor

E1

W

ater pump

EV1-2

Fans

F1

High pr

essur

e s

w

itch

F2

Lo

w pr

essur

e s

w

itch

F3

Flo

w s

w

itch

F5

W

ater diff

er

ential pr

essur

e s

witch

FU1

Transf

ormer pr

otection fuse

FU2

Auxiliar

y cir

cuit fuse

FU3

Fan pr

otection fuse

FU4

W

ater pump pr

otection fuse

KA1

High pr

essur

e s

w

itch r

ela

y

KA2

W

ater pump contr

ol r

ela

y

KM1

Compr

essor contactor

QF1

Chilling assembl

y pr

otection s

witch

QM1

Compr

essor thermal o

verload s

w

itch

QS1

Door lock disconnector s

witch

R1

Compr

essor oil sump heater

R2

Fr

ost heater

RD1

Red lock

out warning light

SA1

On-off s

witch and/or timer input

SA2

Summer

-winter s

w

itch input

TC1

Saf

ety transf

ormer

YV1

Cycle r

ev

ersal valv

e

Z1

Compr

essor

1

Switch not included in the suppl

y

3

Heat pumps onl

y

4L

ights not supplied

5

Optional on-off s

witch and timer

6

Optional summer

-winter s

w

itch;

for cooling-onl

y mod-

els terminals 8-9 closed