EN

ENGLISH

USERS MANUAL

Please read these instructions and recommendations carefully.

1. Operator training:

Activities carried out at heights are dangerous and can be the cause of

serious accidents, even deadly; the user accepts sole responsibility for

any accident following the incorrect use of the equipment.

Operators must receive the necessary training prior to using the

equipment (operators must be aware of safety measures and

techniques). This manual provides a number of examples of incorrect or

wrong use.

2. Use:

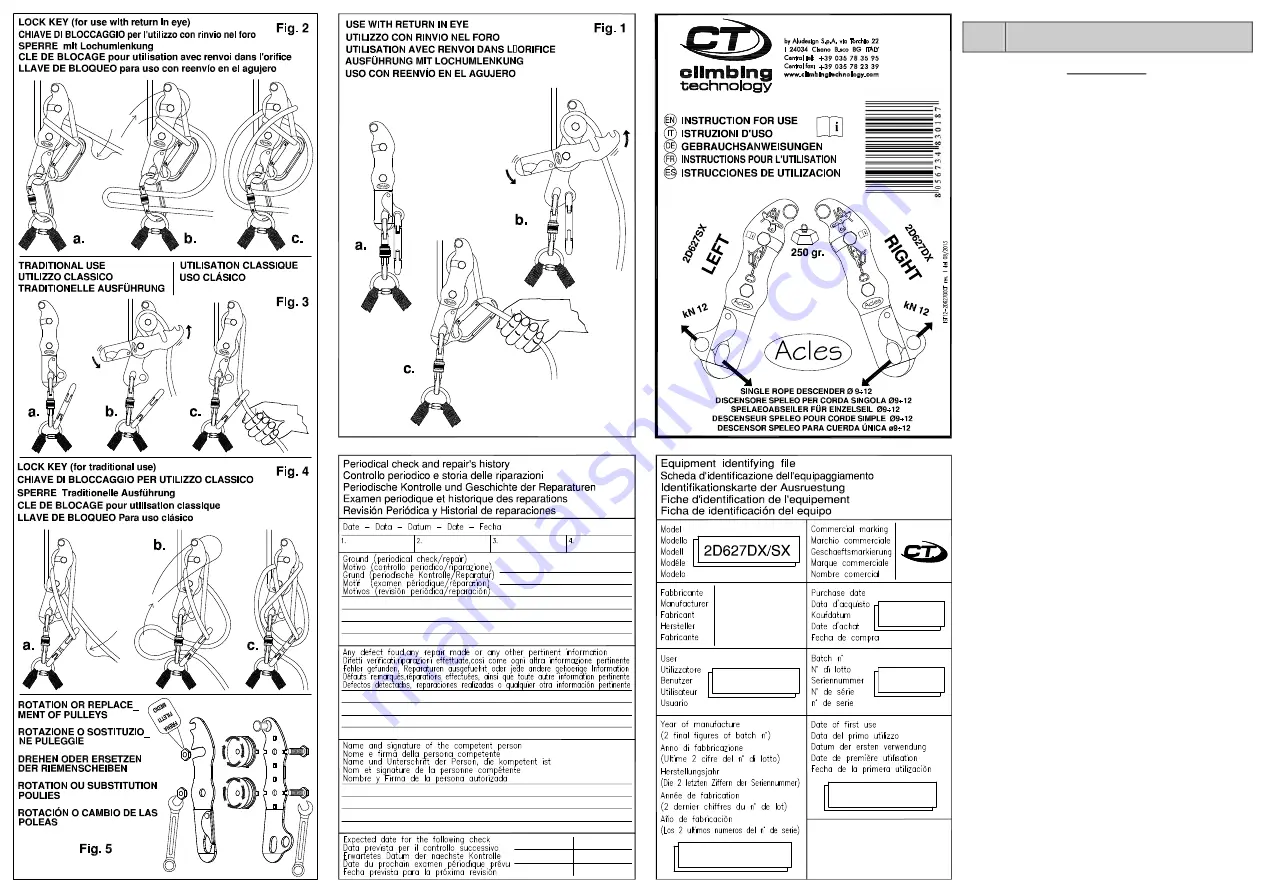

The equipment must be fixed to the harness by a connector and

automatic or manual lock nut (EN 12275); the rope must be inserted as

shown in figures 1 and 3. A rope return connector must be used (we

recommend a steel cable) which can be placed inside the harness link,

or better still, in the hole provided (Fig. 2). Better speed control when

descending can be obtained by placing the rope return in the hole

provided: by varying the angle at which the rope comes out of the

connector great differences in attrition can be obtained even if small

diameter (

∅

9 mm) or dirty cables are used. Use on suitable ropes (for

potholing or mountain climbing)

∅

9 – 12 mm. It is also possible to use

ropes with a diameter of 8 mm, however these ropes brake more slowly.

Figure:

Fig. 1 – Return rope passing through hole

Fig. 2 – Lock key with return rope passing through hole

Fig. 3 – Traditional use

Fig. 4 – Traditional lock key

3. DO NOT RELEASE THE ROPE WHEN IN USE

as descent is not self locking;

Avoid overheating the equipment by descending at moderate speeds;

we recommend that the rope be wet prior to use.

Range of temperature – 30°C/+70°C.

4. Maintenance:

Always check that the equipment is in good state before and during use.

Always replace the equipment if subjected to excessive stress or if there

is some uncertainty as to its condition. Replace the equipment if there

are signs of wear and tear or corrosion. Do not place near sources of

heat; Do not allow the equipment to come into contact with corrosive

substances or salt water (the same procedure must be used when the

equipment is covered in soil or mud); if it is dirty wash immediately with

fresh water at ambient temperature (approx. 20°C) and if necessary use

a ph neutral soap; rinse with clean water; use a dry cloth to remove any

water or other residues. Never place the equipment near sources of heat

when drying. We recommend that the equipment be checked by qualified

people (e.g. the manufacturer) and to record that it has been serviced in

the booklet provided.

5. Storage:

Remove the equipment from the packaging and keep in a well aired, cool

dry place. The equipment must not be exposed to sources of light.

Do not store the equipment in areas containing corrosive substances or

sources of heat. Do not bring the equipment into contact with sharp

objects which may damage it. Avoid ultra-violet light.

Never store the equipment without having dried it properly and avoid

storing it in saline areas/environments.

6. Length of service and wear and tear:

The useful life of the equipment depends on the frequency and

conditions of use. If it is used frequently, we advise you to replace it

every 2 years. If used occasionally it may last approximately 5 years.

Avoid exposing the equipment to sources of heat (> 70°C) and

chemicals or solvents. In each of these cases, just as for visible flaws,

the equipment must be replaced without hesitation.

7. Rotation and replacement of pulleys:.

Fig. 5. The pulleys can be rotated in 4 positions so that wear is even and

braking better. Avoid using excessively worn pulleys as the rope may

come into contact with the steel screw damaging the equipment itself

and the rope. N.B. tighten the screws and lock the nuts using a medium

strength thread adhesive.

8. Guarantee:

The equipment is guaranteed for 3 years against all manufacturing and

material defects; wear and tear, tampering or incorrect storage are not

covered by the guarantee.