5

CTK 240 mobile air dehumidifier

The units are shipped in sturdy

transport packaging. Immediately

check the unit on delivery and make

a note of any damage (please take

photos of the damage) or missing

parts on the delivery note. Inform

the forwarding agent and your

contractual partner.

Please retain the packaging for

returns.

Claims under guarantee made at a

later date will not be accepted.

5.0 Transport and

packaging

4.0 Intended use

The units are designed exclusively

for drying and dehumidification

purposes on the basis of their

structural design and equipment.

The units must not be used for any

other purpose.

The units are only permitted to

be operated by people with the

relevant training and understanding

of how to handle them.

Any different or additional

use is a non-intended use. The

manufacturer/supplier assumes no

liability for damages arising from

non-intended use. The user bears the

sole risk in such cases.

Intended use also includes working

in accordance with the operating

and installation instructions and

complying with the maintenance

requirements.

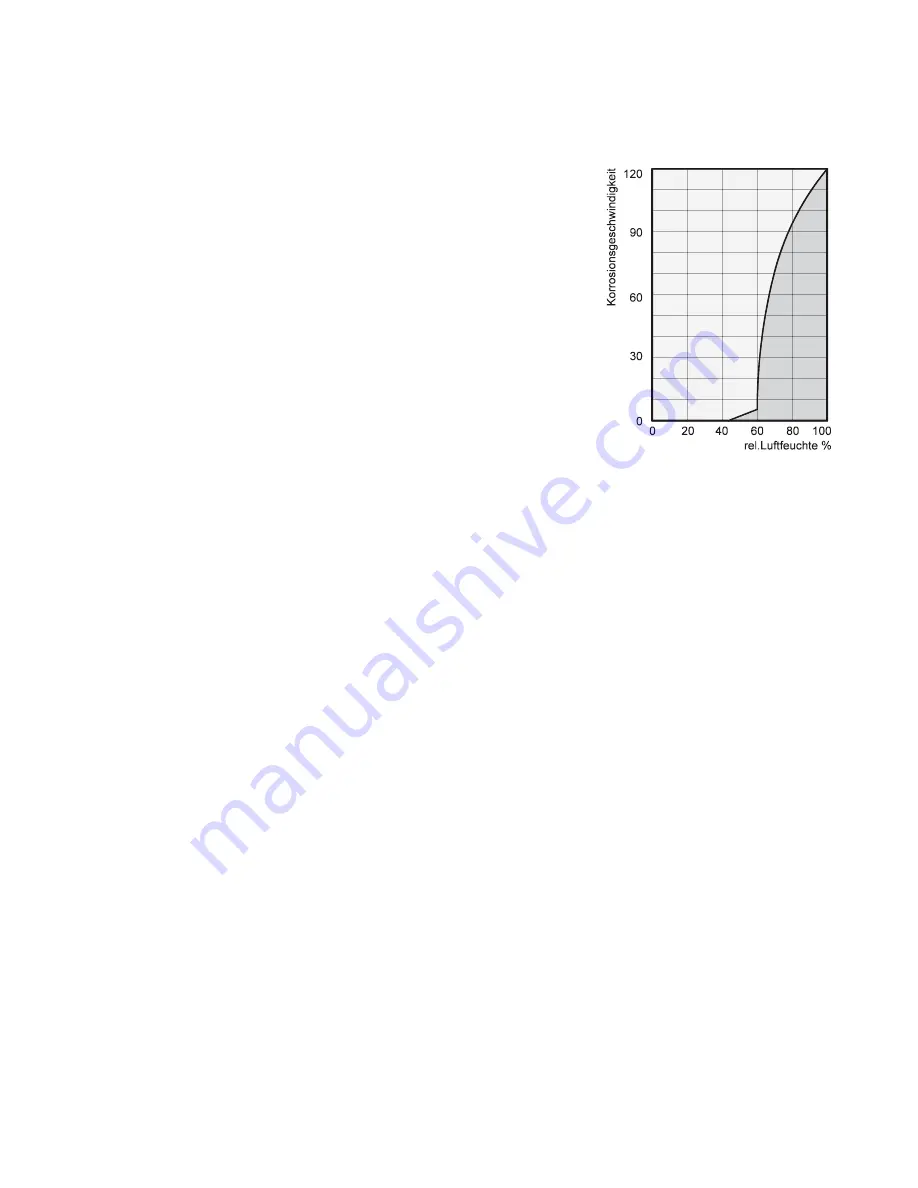

It is evident that the corrosion rate

below 50% relative humidity (RH) is

low, and below 40% is negligible.

The corrosion rate increases

significantly above 60% RH.

This threshold for damage as the

result of humidity also applies to

other materials, such as powdery

substances, packaging, wood and

electronic units.

Buildings may be dried in a variety

of ways:

1.

By heating and air exchange:

The air in the room is heated in

order for moisture to be removed

and then this air is fed outside.

All of the energy that is involved

is lost together with the moist air

that is released.

2.

By air dehumidification:

The moist air that is present

within an enclosed space is

continuously dehumidified

according to the condensation

principle.

The correlations occurring when

air is dehumidified are based on

physical laws.

These are depicted here in graphical

form in order to provide you with

a brief overview of the principles of

air dehumidification.

Using Climia air dehumidifiers

•

Even if windows and doors

are well insulated, water and

moisture are still capable of

penetrating thick concrete walls.

•

The water required for setting

in the production of concrete,

mortar and plaster etc. may only

be diffused after 1-2 months.

•

Even moisture trapped in the

masonry after high-water or a

flood is released very slowly.

•

The same is also true of moisture

contained in stored materials for

example.

The moisture (water vapour)

released from parts of a building

or materials is absorbed by the

surrounding air. As a result, the

moisture content increases, which

ultimately gives rise to corrosion,

mould, rot, peeling of paint and

other unwanted damage.

By way of example, the diagram

shows the corrosion rate of metal in

different levels of humidity.

6.0 Air dehumidification

Summary of Contents for CTK 240

Page 1: ...CLIMIA CTK 240 mobile air dehumidifier Operating manual Edition 1 0 English ...

Page 2: ......

Page 21: ...21 CTK 240 mobile air dehumidifier Notes ...

Page 22: ...22 CLIMIA ...

Page 23: ...23 CTK 240 mobile air dehumidifier ...

Page 24: ...Intakt GmbH Climia Klima und Wärmetechnik Niemeierstraße 13 D 32758 Detmold ...