M03I40M7-03 15/11/07

page

27

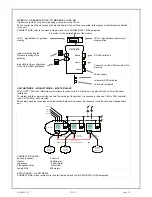

CONTROL

CONTROL INTERFACE

COOL cooling

HEAT heating

unit status (ON – ECO –

OFF )

Enabled timing bands

INLET temperature

alarm

; OK

OUTLET temperature

inserted steps on total

ALARM menu access

Current set point

HEAT / COOL

changement

SET POINT, TIMING

BANDS, CLOCK access

off = unit OFF

on = unit ON

Stata MENU access

ON / OFF unit

HELP parameter

descriptions

Back to previous shield

Back to main menu

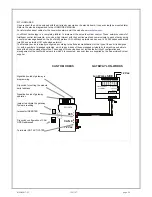

UNIT START-UP

To turn the unit on or off, hold the ON/OFF switch down for a few seconds. When the unit is on, the “ON” message is

displayed; when the unit is off, the “OFF” message is displayed.

It is also possible to access the different menus when the unit is in the “OFF” mode.

It is possible to check the ON/OFF condition at a distance, using a remote device (see the ELECTRICAL CONNECTIONS

chapter).

CHARACTERISTICS

THERMOREGULATION

The thermal regulation is based on the INLET temperature.

The unit is set for a specific TOTAL DIFFERENCE between the inlet and outlet water temperatures.

Usually the designed difference is 5°C, in the event that a different value is foreseen, the 17 and 18 parameters must be set

again by the assistance center.

According to the total difference, the system defines the level of difference that each compressor can give : the STEP

DIFFERENCE.

The regulations tend to gradually insert the compressors when the inlet temperature is over the set-point + the step difference.

The compressors are activated one per time at the end of the SCANNING TIME.

This time varies according to the gap between the water inlet temperature and the Set-point value. The higher the gap value is

(both negative and positive), the shorter the interval among the scanning points will be.

The value of the scanning time is displayed at the status 6; when the status 7 has reached the value of the status 6, the

request of operation of the compressor is activated.

The counting of the scanning time starts together with the activation of the compressor.

The compressor to be activated is chosen to make the shut circuits operate in order to minimize the wear of the entire

refrigerating circuit, as well as the single compressor.

At the end of the counting, if the inlet temperature is higher than the step difference, another compressor is inserted.

temp. H2O > set-point + step difference.

What above described is referred to the COOLING operating, in HEATING the logici s the same but overturned (compressor

insertion for outlet temp. < set-point – step jump).

SET-POINT COMPENSATIONS

The compensations are evolved functions that aim at protecting the compressors and fit as much as possible, the operation of

the unit to the characteristics of the system and its use.

The compensations make the time of the compressors’ operation longer and limit the number of starts-up, to make them delay

the insertion time by adding an offset.

•

The compensation on the DURATION is useful when the water contained in the system is limited.

•

The compensation on the CHARGE is useful when a variable charge is present.

Optional components are necessary; the modifications of the parameters performed by the assistance centers have to be

performed to enable and configure. In industrial applications, where a precise control of the temperature is necessary, it is

possible to deactivate the COMPENSATIONS. The Status menu displays the value of the compensations on ext. temp. (status

9) and WR (status 10).