M03I40M7-03 15/11/07

page

39

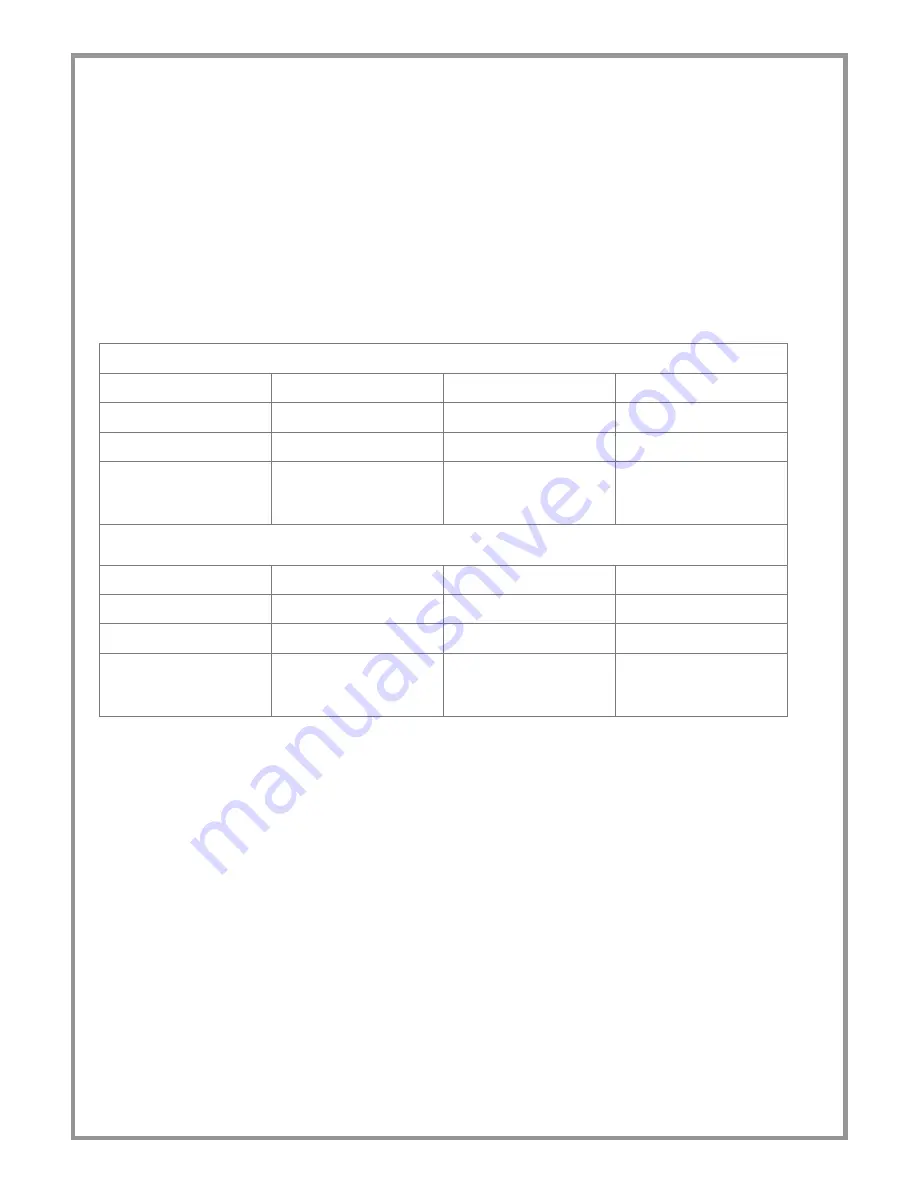

REFRIGERANT TABLES

THIS SECTION IS DEVOTED ONLY TO QUALIFIED TECHNICIANS THAT KNOW THE FOLLOWING:

•

THE OPERATIONAL PRINCIPLES OF THE REFRIGERATING CIRCUIT OPERATION

•

THE MODES OF DETECTING TEMPERATURE AND PRESSURE

•

THE RISKS RELEVANT TO THESE OPERATIONS

The data of the tables allow the testing of the refrigerating

circuit operation by the detection of a few objective

parameters.

The data are significant if they are detected

simultaneously and while the refrigerating circuit is

running.

•

Liquid temperature

•

Return pressure

•

Return temperature

•

Condensing pressure

OVERHEATING

= return temperature – Saturation temperature

R22 R407C

R410A

Return pressure

3.8 bar

3.8 bar

7.2 bar

Return temperature

7.3 °C

7.3 °C

7.3 °C

overheating

7.3 – ( - 1.13 ) =

8.43

°C

1.3 – 1.18 =

6.12

°C

for calculation consider the Td

(dew point)

7.3 – 0.8 =

6.5

°C

SUBCOOLING

= condensing temperature (pressure *) – liquid temperature

R22 R407C

R410A

Condensing pressure

18.6 bar

18.6 bar

29.6 bar

Liquid temp.

42.9 °C

42.9 °C

45 °C

subcooling

50.39 – 42.9 =

7.49

°C

44.74 – 42.9 =

1.84

°C

for calculation consider the Tb

(bubble point)

49.91 – 45 =

4.91

°C

* It is important that the condensation pressure is detected as close as possible to the point where the liquid temperature is

detected, in the event that the calculation will be effected by the losses of charge (and, therefore, of temperature) caused by

the refrigerating circuit components placed between the two measurement points.

For R410A the glide was not considered, since it is close to 0.

The values in the tables refer to a specific refrigerant supplier; slight differences are possible with other suppliers.

Pg = P gauge = relevant pressure (read on the pressure

gauge)

Ts : saturation pressure

Td = dew point temperature

Tb = bubble point temperature