M03I40M7-03 15/11/07

page

44

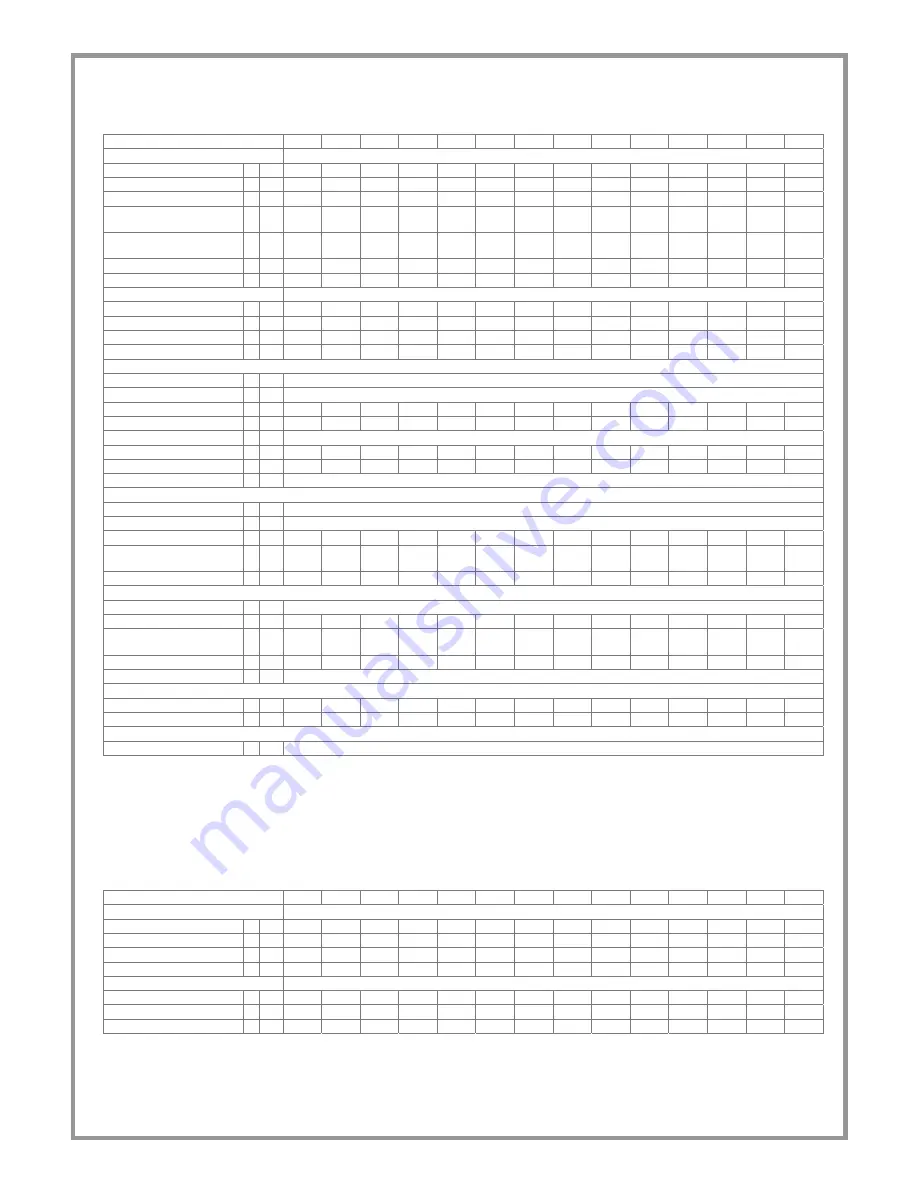

Acoustic configuration: Standard (ST)/Extremely low noise(EN) / Energy efficiency: Efficiency class B

Size

2.160 2.180 2.220 2.250 2.280 2.300 2.320 2.340 2.360 2.420 2.450 2.480 2.540 2.600

COOLING

Cooling

capacity

1

kW 408 455 562 620 698 773 828 903 952 993 1049

1171 1295 1458

Compressor power input

kW 86 96.5 118 130 147 162 177 187 196 208 223 246 271 308

Total power input

kW 87 97.5 119 131 148 163 178 188 197 209 224 247 272 309

Heating capacity total

recovery

2 kW 473 528 649 718 809 894 962 1039 1095 1148 1217 1358 1503 1692

Heating capacity partial

recovery

2

kW

74.2 82.7 102 112 127 140 151 163 172 180 191 212 235 265

EER

4.69 4.67 4.73 4.72 4.71 4.73 4.66 4.8 4.82 4.74 4.68 4.74 4.75 4.72

ESEER

5.28 5.26 5.33 5.32 5.3 5.33 5.25 5.41 5.43 5.34 5.27 5.34 5.35 5.32

HEATING

Heat

output

3 kW 473 528 649 718 809 894 962 1039 1095 1148 1217 1358 1503 1692

Compressor power input

kW 107 119 146 161 184 201 218 231 243 258 275 303 337 381

Total power input

kW 108 120 147 162 185 202 219 232 244 259 276 304 338 382

COP

4.4 4.4 4.42 4.44 4.37 4.42 4.39 4.48 4.48 4.43 4.41 4.47 4.44 4.43

COMPRESSOR

Type of compressors

4

SCREW

No. of Compressors

Nr

2

Rated

power

(C1)

HP 80 90 110 125 140 140 160 160 180 210 210 240 270 300

Nominal

Power

(C2)

HP 80 90 110 125 140 160 160 180 180 210 240 240 270 300

Std Capacity control steps Nr

STEPLESS

Oil

charge

(C1)

l 11 11 22 19 19 19 35 35 35 35 35 25 25 25

Oil

charge

(C2)

l 11 11 22 19 19 35 35 35 35 35 35 25 25 25

Refrigerant circuits

Nr

2

INTERNAL EXCHANGER

Type of internal exchanger 5

S&T

No. of internal exchangers Nr 1

Water flow rate

l/s 19.5 21.7 26.8 29.6 33.3 36.9 39.6 43.1 45.5 47.4 50.1 55.9 61.9 69.7

internal exchanger

pressure drop

kPa 61 56.2 51.4 61.1 75.2 66.9 58.9 39.9 43.8 78.6 52.2 66.3 79.3 70.9

Water content

l 164.4 159.3 263.3 263.3 263.3 248.3 241.2 409.6 409.6 418.6 409.6 400.9 400.9 461.8

EXTERNAL EXCHANGER

type of external exchanger 6

S&T

Water flow rate

l/s 23.6 26.4 32.5 35.8 40.4 44.7 48 52.1 54.9 57.4 60.8 67.7 74.8 84.4

external exchanger

pressure drop

kPa 31.7 29.7 34.5 33.4 34.8 33.4 30.5 33 34 36.9 36.3 35.9 34.9 30.9

Water content

l 38 43 49 54 59 67 75 75 75 80 85 95 101 131

Quantity

Nr 2

CONNECTIONS

Water

fittings

7

5" 5" 6" 6" 6" 6" 6" 8" 8" 8" 8" 8" 8" 8"

Water

fittings

7

5" 5" 5" 5" 5" 5" 5" 5" 5" 5" 5" 5" 5" 6"

POWER SUPPLY

Standard power supply

V 400/3/50

(1) data referred to the following conditions :

internal exchanger water = 12/7°C

external exchanger water = 30/35°C

(2) recovery exchanger water=40/45°C

(3) data referred to the following conditions :

external exchanger water = 40/45°C

internal exchanger water = 12/7°C

(4) DSW = twin-screw compressor

(5) S&T = tube bundle

(6) S&T = tube bundle

(7) Fittings with flexible joint and solder pipe connection

OPERATING LIMITS (COOLING)

Size

2.160 2.180 2.220 2.250 2.280 2.300 2.320 2.340 2.360 2.420 2.450 2.480 2.540 2.600

EXTERNAL EXCHANGER

Max water inlet temperature

1

°C

51 51 51 51 51 51 51 51 51 51 51 51 51 51

Max water inlet temperature

2 °C

55 55 55 55 55 55 55 55 55 55 55 55 55 55

Max water inlet temperature

3 °C

62 62 62 62 62 62 62 62 62 62 62 62 62 62

Min. water outlet temperature

1

°C

26 26 26 26 26 26 26 26 26 26 26 26 26 26

INTERNAL EXCHANGER

Max water inlet temperature

°C 20.5 20.5 20.5 20.5 20.5 20.5 20.5 20.5 20.5 20.5 20.5 20.5 20.5 20.5

Min. water outlet temperature

4

°C

5 5 5 5 5 5 5 5 5 5 5 5 5 5

Min. water outlet temperature

5

°C

-8 -8 -8 -8 -8 -8 -8 -8 -8 -8 -8 -8 -8 -8

(1) unit at full load: internal exchanger water 12/7°C

(2) capacity-controlled unit (automatic capacity control)

(3) unit not operating

(4) Standard Version

(5) Low temperature version

Fluid with ethylene glycol of 40%