M0G940E8-00 04/07/08

pag

13

POSITIONING

GENERAL

For installing air-conditioning systems, it is necessary to

consider the following:

•

the technical spaces necessary for the machine and

system

•

the place where the machine will be installed

•

the transport of thermal carrier fluids and relevant

connections to the unit:

o

water

o

air

o

refrigerant (unit in more sections)

•

electrical connections

If these aspects are not evaluated carefully, they can affect

the performances and the working life of the unit.

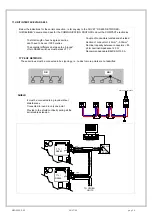

FUNCTIONAL CLEARANCES

When placing the unit, please respect the functional

clearances indicated in DIMENSIONS section.

The functional spaces need to be observed because of the

following:

•

to guarantee the good operation of the unit

•

to allow the performance of all maintenance operations

•

to protect the authorized operators and exposed

people

If more units are placed close to one another, the functional

spaces must be doubled.

POSITIONING

1. The units are designed for

OUTDOOR

installations,

performed in fixed positions and in areas accessible

only to qualified and authorized personnel

2.

SAFETY VALVE

(only if present on the unit) : the

installer is responsible for evaluating the opportunity

of installing drain tubes, in conformity with the local

regulations in force ( EN 378 )

3.

Install the unit

raised

from the ground

4.

avoid installations in places subject to

flooding

5.

Consider the maximum level which can be reached by

snow

6. Verify that the fixing/supporting points are level and

suitable to support the

weight of the unit

(see the

weight and the weights distribution)

7.

It is recommended to put the unit on specific

antivibration devices

Each support point of the unit sustains a different

weight. Therefore, each anti-vibration device is sized

for a specific support point, and can only be placed

there. The anti-vibration devices must therefore be

placed in accordance with the instructions provided

with them and with the dimensional drawings in which

the support points are indicated by W1 , W2 , W3 etc .

On each anti-vibration device (if provided by CLIVET),

its identifying code is stamped, for example C6100100

Flexible joints

are necessary on all the hydraulic/

aeraulic connections (the joints are not supplied by

Clivet)

8.

Anchor

the unit to the ground; foresee windbreak

barriers in case of places where there are strong

prevalent winds .

9. During winter operation, a considerable amount of

condensation

water is produced, which must be

removed from the unit.

Make sure that removal of condensation water does

not create any problems for persons or property, such

as dripping from balconies, onto walkways, etc.

For long periods of heat pump operation with external

temperature below 0°C, the condensation might

freeze,

causing a build-up of ice. The installation of

anti-freeze heating elements should be considered.

For the units that are equipped with a condensation

drain, this is shown on the dimensional drawing.

10. The choice of the location of the unit is of fundamental

importance for correct operation; to avoid:

−

obstacles

that block the flow of air

−

difficulty in air

circulation

−

leaves

or other objects that may block the

exchanger coils

−

winds

that contrast or excessively assist the air

flow

−

phenomena of

stratification

or air

re-circulation

−

nearby

sources

of heat (chemney, extractor ecc)

−

positioning under the round level or near very high

walls

The previous situations cause working anomalies or

stop the machine and cause:

−

during SUMMER operation, increase of the

condensation pressure with the decay of

performances and possible stops due to high

pressure.

−

during WINTER operation, decrease of the

evaporation pressure with increase to the amount

of defrosting and consequent decay of the

performances and possible stops due to high

pressure

Summary of Contents for WSAN-XPR 21

Page 2: ......

Page 25: ...M0G940E8 00 04 07 08 pag 25...

Page 48: ...M0G940E8 00 04 07 08 pag 48...

Page 49: ...M0G940E8 00 04 07 08 pag 49 TECHNICAL DATA...

Page 59: ......