M0G940E8-00 04/07/08

pag

18

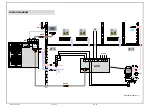

CONNECTION TO THE MAINS

1. Make sure that the sectioning device at the beginning of the unit’s power line is opened, locked and equipped with a signal.

2. Open the general line disconnecting switch (if present)

3. Verify that the net is in conformity with the data shown in the registration plate placed on the electrical board.

4. Check the dimensional drawing for the input of the electrical lines

5. Take away the closing plate placed on the electric board (ONLY IF PRESENT) and drill a hole through it to pass the

cables through)

6. Protect the cables, using the fairlead of an adequate size.

7. Using the layout of the electrical diagram, single out the connecting terminals of the electrical supply cables, of the neutral

(if foreseen) and the PE protection cable

8. Connect the cables to the relevant terminal boards

9. Before supplying power to the unit, make sure that all the safety devices that were removed during electrical connections

are positioned again.

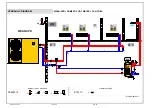

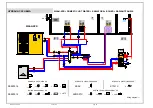

SYSTEM COMPOSITION

The system is composed of the following modules; some are optional that could be not installed.

Some are supplied in packages separate from the unit: check the shipping document descriptions

Test

Comfort

ECO

ELFO

ENERGY

!

!

!

USER AMBIENT TERMINAL

Permits setting the unit function modes (cooling – heating, ECO) and to display the alarms

(ELECTRIC, REFRIGERATOR, WATER).

This is standard on certain types of unit

L

N

91

92

ST

AT

US

SE

T

AL

AR

M

2

1

REMOTE KEYPAD

OPTIONAL

The interface terminal enables to control every machine function, to program the different

adjustment parameters and possibly to display the unit statuses and alarms.

It remotely repeats all functions available on the machine keyboard

SERVICE KEYPAD

OPTIONAL

Useful during the maintenance operations; it is fitted with a cable with automotive rapid connector

for the utilisation in proximity to the unit.

The functionalities are analogous to the remote keypad ones.

MAIN ADJUSTMENT MODULE

It controls unit (inlets, outlets, configuration parameters)

EXPANSION PLUG-IN MODULE

It is connected to the main module by a coupling comb.

This may be fitted on the unit depending on the unit type and the accessories that are installed.

8

1 2 3 4 5 6 7

CN

2

12

10

9

11

16

+5

V

13

14

15

gn

d

19

17

18

2

1

20

SERIALE

TTL / RS485

CN

1

gn

d

1

2VAC

+-

SERIAL CONVERTER TTL/RS485

OPTIONAL

Plugged-in in the main module on the electric board (see lay in the wiring diagram). It is possible

to connect up to 127 units with a single supervision system.

The connection with a PC must use a RS485/232 converter; the serial line RS232 can be max. 10-

m long.

CONNECTIONS:

make reference to the electrical panel and to the SIGNALS AND DATA LINES paragraph

Summary of Contents for WSAN-XPR 21

Page 2: ......

Page 25: ...M0G940E8 00 04 07 08 pag 25...

Page 48: ...M0G940E8 00 04 07 08 pag 48...

Page 49: ...M0G940E8 00 04 07 08 pag 49 TECHNICAL DATA...

Page 59: ......