27

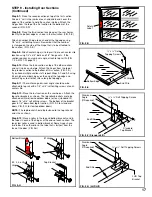

STEP 18 – Attaching an Automatic Opener

IMPORTANT:

To avoid damage to your door, you must

reinforce the top section of the door in order to provide a

mounting point for the opener to be attached. Refer to the

section of this manual titled Reinforcing the Top Section on

page 18 for specific instructions. Failure to reinforce the door

as illustrated will void the warranty on your door.

To avoid risk of strangulation or personal injury to

children, if your door has a pull rope, you must remove

the pull down rope when you install an automatic garage

door opener.

IMPORTANT:

When installing an automatic garage door

operator, make sure to follow manufacturer’s installation and

safety instructions carefully. Remove the pull down rope and

unlock or remove the lock. If attaching an operator bracket

to the wooden anchor pad, make sure the wood anchor pad

is free of cracks and splits and is firmly attached to the wall.

Always drill pilot holes before attaching lag screws.

The operator arm will usually be attached to the vertical

reinforcement member at roughly the same height as the top

roller of the door. Attach the opener arm to the reinforcement

as shown in Figures 18-B to 18-C. To prevent the top of the

door from bending, the opener rail should be mounted no less

than 2" and no greater than 5" from the face of the door with

the door in the open position (FIG. 18-A). Additionally, when

the door is closed, the portion of the operator arm attached to

the door should be at angle of approximately 60 degrees from

the vertical.

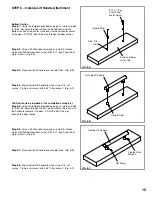

FIG. 18-B (Doors with odd number of panels)

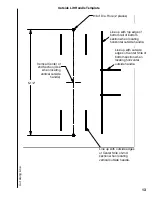

FIG. 18-A

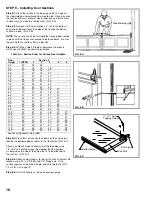

FIG. 18-C (Doors with Angle Iron Reinforcement Bracket

and Stile in Center of Door)

Opener Arm Attachment To Horizontal Angle Or Strut

Opener Arm

Punched

Angle

Horizontal Angle

Or Strut

Punched

Angle

Horizontal

Angle

Or Strut

Opener Arm

Lock These Nuts

Together Securely

Opener Arm Attachment To Vertical Angle

Horizontal

Punched

Angle

3/8” x

1-1/2”

Hex Bolt

Opener Arm

Vertical

Punched

Angle

3/8”

Hex Nut

Mounting Surface

Of Door

Vertical Punched

Angle

Lock These

Nuts Together

Securely

Opener

Arm

Leave

Clearance

Opener Rail Mounting Distance

Ceiling

Opener Rail

Horizontal Track

Keep Clearance at 2” – 5”

60

degrees