3

Table of Contents

Introduction and Opening Preparation

ST

EP 1 – Things to Know Before You Begin

3

STEP 2 – Read Safety Information

4

STEP 3 – Check Headroom, Backroom, Sideroom

5

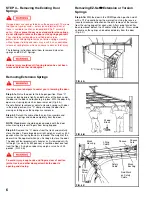

STEP 4 – Removing the Existing Door Springs

6

STEP 5 – Removing Door Sections and Track

7

STEP 6 – Preparing the Opening

7

Preparing the New Door

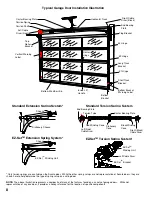

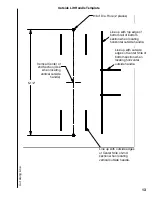

Typical Garage Door Installation Illustration

8

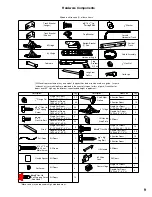

Hardware Components

9

Torsion Spring Hardware Components

10

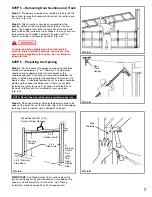

Installing the New Door

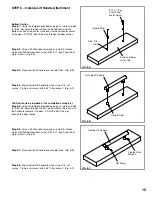

STEP 7 – Preparing Bottom Section

11

STEP 8 – Outside Lift Handle Attachment

15

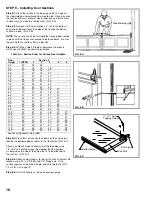

STEP 9 – Installing Door Sections

16

STEP 10 – Reinforcing the Top Section for Opener Attachment

18

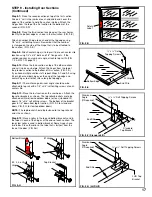

STEP 11 – Assembling and Installing Track

19

STEP 12 – Lock Installation (if included)

21

STEP 13 – Pull Rope

21

STEP 14 – Spring Installation

22

STEP 15 – Attaching an Automatic Opener

27

Maintenance/Adjustments/Options

Painting and Windows

28

Maintenance

29

Checking and Adjusting the Door

29

Replacement Parts

29

STEP 1 – Things to Know Before You Begin

Read the instructions completely before starting the installation

of the door. Becoming familiar with the components before

assembling the door will reduce the installation time.

Be sure all hardware components for your new door are

included before removing existing door (see pages 6,7). If your

door is missing any parts, call the toll-free Consumer Services

number listed on the front of this manual.

Allow enough time to do the work; removing an existing door

will take approximately 1-3 hours.

An assistant may be required for lifting the unsprung door. It

can weigh from 100 to 800 pounds.

A typical installation takes between 9 and 12 hours to

complete.

Keep in mind when planning the installation that the garage

will be open and unsecured when disassembling the old and

assembling the new door.

If the garage door is the only opening in the structure make

sure everything you need is inside. You will have no way of

leaving the garage until the track is assembled and installed.

This will take approximately 5 hours.

To avoid damage to the door, you must reinforce the top

section of the door in order to provide a strengthened

mounting point for attachment of an automatic opener (see

page 18).

Low Headroom doors require special instructions. Options for

doors with low headroom can be found on page 5. Purchase of

additional hardware may be required. Check headroom

requirements in the chart on page 5 before beginning.

To avoid installation problems which could result in personal

injury or property damage, never reuse old track or hardware.

Doors installed in high windload regions (Florida and other

high wind prone areas) may require additional reinforcement

beyond what is detailed in these instructions. Please refer to

supplemental instructions for these areas.

Express warranties apply only to doors installed using original,

factory-supplied sections, parts, and hardware installed in strict

accordance with these instructions.

Tools Needed

“C” Clamps or Locking Pliers

Hammer

Screwdriver

Tape Measure

Level

Socket wrench kit

Pliers

Drill, 9/64”, 3/16", 1/4", & 3/8" drill bits, and 7/16" socket bit

Step ladder

Saw horses (with carpet or other soft material on top surface; 2

for doors up to and including 10’0”, 3 for doors over 10’0”) or

other supports for placing section on while assembling

Hacksaw

Wood Saw

T-Square

3/32” Allen (Hex) Wrench

Two 1/2" diameter, 18" long cold rolled solid steel winding bars

(NOTE: Winding bars are available at most hardware stores)

Locking Pliers

Additional Material Required

Light household oil

1-1/4" x 1-1/4" Minimum punched angle

- 13 ga. (3/32") minimum thickness for Operator

Reinforcement (see page 18)

- 16 ga. (1/16") minimum thickness for rear track hangers

on doors weighing up to 300 lbs. that use torsion

springs. If your door exceeds these weight limitations, or

if you do not know the weight of your door, 13 ga. angle

should be used. (See page 20)

Eight 3/8" x 1" bolts and nuts for rear track hangers

Six 5/16" x 11/2" lag screws for rear track hangers

Twelve 10d 3" nails

Stop Molding

Wood Block

Wood Anchor Pad for Torsion Spring (See page 20 for size and

material specifications)

Rope